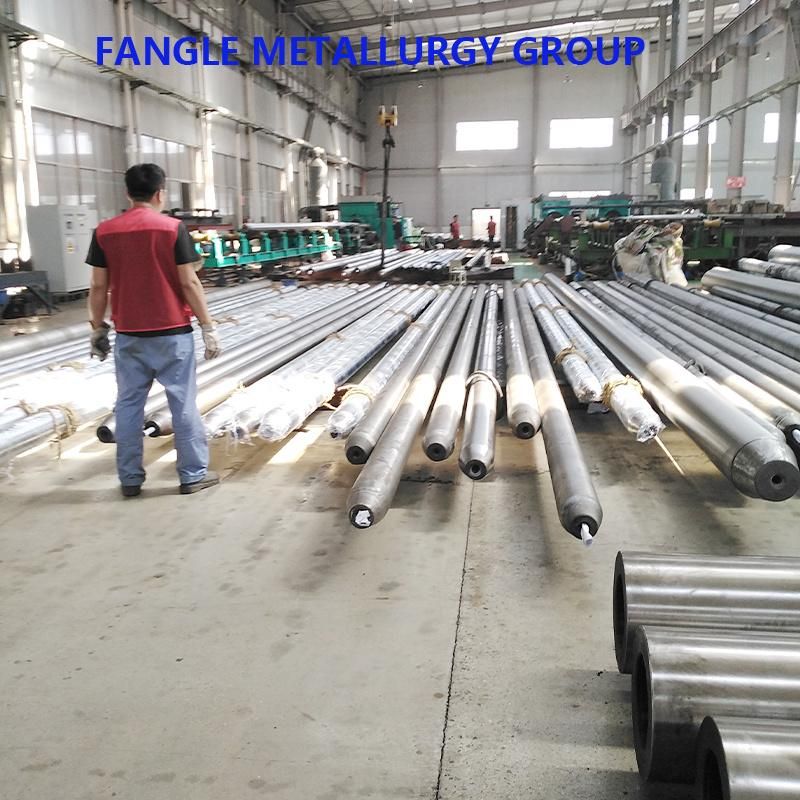

H13 Mpm Mandrel Bar for Producing Seamless Steel Pipes

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:Forging Operation

- Application Range:Mpm, Pqf, Fqm Mill

- Material Type:X38crmov51-H11; X35crmov05-H13

- Transport Package:Woodern Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- HS Code:84559000

- Production Capacity:20000 Tons,Year

Description

Basic Info.

Model NO. Forging Operation Application Range Mpm, Pqf, Fqm Mill Material Type X38crmov51-H11; X35crmov05-H13 Transport Package Woodern Case Specification Export package Trademark FANGLE Origin China HS Code 84559000 Production Capacity 20000 Tons/YearProduct Description

The Mandrel is the important tool for MPM or FQM during seamless tube production .during production ,it needs 6-7 pieces mandrel to stand by in turns .its surface temperature will reach 700ºC during production and then cooled to 80-120ºC after production ,it requires good quality and long lifetime. We can produce mandrel diameter from 100mm to 500mm and length is max 20m .We have the ability to produce mandrel bars for MPM and FQM, with yearly capacity around 20000 tons.Production process:1) forging 2) rough machining

3) magnetic test 4) heating treatment

5) ultrasonic test 6) finish machining 7) chromium plating

8) thread phosphating 9) package