Aluminum Metal Rolling Shutter Door Making Machine in Automatic Door

Xiamen Xinhonghua Machinery Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:Automation

- Certification:SGS

- Warranty:12 Months

Base Info

- Model NO.:JM85

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Model No.:Jm85

- Application:Machinery & Hardware

- Type for Cutting Machine:Hydraulic Cutt

- Type for Fold-Bending Machine:Hydraulic Fold-Bend Machine

- Dimension:4000*900*1400mm

- Weight:1500kgs

- Working Speed:8-12m,Min

- Forming Steps:14

- Effective Width:85mm

- Thickness:0.6-0.8mm

- Transport Package:Standard Package for Export

- Specification:SGS

- Trademark:XHH

- Origin:Xiamen, China

- HS Code:84552290

- Production Capacity:20sets,Month

Description

Basic Info.

Model NO. JM85 Customized Customized Advantage Use Widely Condition New Model No. Jm85 Application Machinery & Hardware Type for Cutting Machine Hydraulic Cutt Type for Fold-Bending Machine Hydraulic Fold-Bend Machine Dimension 4000*900*1400mm Weight 1500kgs Working Speed 8-12m/Min Forming Steps 14 Effective Width 85mm Thickness 0.6-0.8mm Transport Package Standard Package for Export Specification SGS Trademark XHH Origin Xiamen, China HS Code 84552290 Production Capacity 20sets/MonthProduct Description

JM85 Metal Rolling Shutter Door Foming Machine detailed informations are as follows:

(1). Material Thickness: 0.6-0.8mm;

(2). Thickness for common use and test: 0.8mm;

(3). Tolerance: +/-2mm.

Main Accessories:

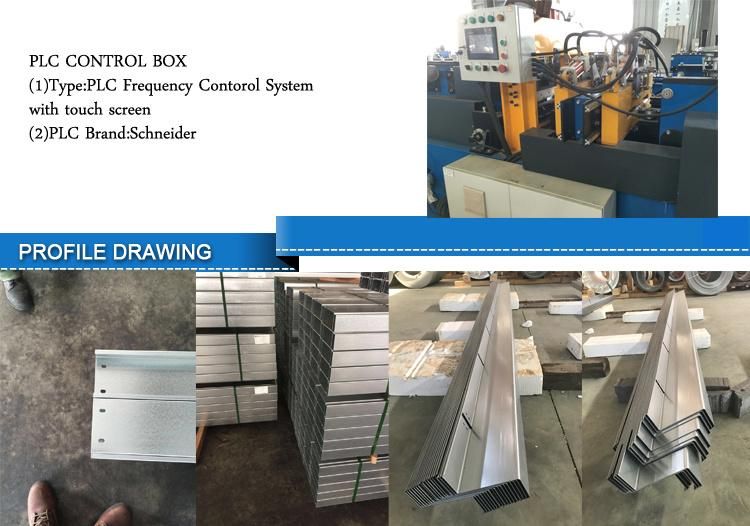

(1). Main Forming Machine;

(2). 3 Tons Manual Uncoiler;

(3). Hydraulic System;

(4). PLC Computer Controlling System With Touch Screen;

(5). Hydraulic Forming Cutter;

(6). Run Out Table (3 sets);

(7). Tools;

(8). Operation Manual.

1. | Size | 4000*900*1400mm |

| 2. | Weight | 1500 KGS |

| 3. | Motor Power | 4 KW |

| 4. | Hydraulic Power | 2.2KW |

| 5. | Volage | 220V/60HZ/3PH |

| 6. | Effective Width | 85mm |

| 7. | Material Width | 136mm |

| 8. | Forming Steps | 14 steps |

| 9. | Forming Speed | 8-12m/min |

| 10. | Thickness for common use and test | 0.8mm |

| 11. | Tolerance | ± 2mm |