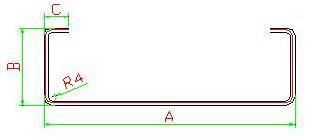

Automatic Adjustale C Purlin Roll Forming Machine Manufacture

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Roll Forming

- Power Source:Electric

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:YX50-100

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Machine Name:C Purlin Roll Forming Machine

- Material:Gi, Carbon Steel, 235MPa

- Thickness:1.5-3.0mm

- Drive System:Gear Box

- Transport Package:No Packing

- Trademark:SAIBO

- Origin:Jiangsu, China

- HS Code:84552210

- Production Capacity:300sets,Year

Description

I: Composition of machine

Roll forming main machine------------------unit

Manual Uncoiler-------------------------------unit

Control panel----------------------------------unit

Hydraulic station------------------------------unit

Manual out table------------------------------unit

Spare tools------------------------------------unit

II: Details of each composition

A: Roll forming main machine

1: Coil width: based on profile drawing

2: Working speed: 12m_15m/min (not include cutting)

3: Roll station:

Roll forming: 14stations )ASTM52100, polished and coated with chrome HRC58-62)

Leveling station: 7 rollers ( up three rollers, down four rollers)

Diameter of roller: 76mm

Material of roller: ASTM1045, polished and coated with chrome HRC58-62

Revising station: 1 station aterial(STM52100 polished and coated with chrome HRC58-62)

4: Material of main shaft: ASTM1045 diameter roller 6mm

5: Main power: 15kw DC motor

6: Forming thickness: 2mm

7: Transmission: By single line chain 1.5inch

8: Machine adopt new stations to make machine stronger

9: Punching:

Base on customer request this machine need one set of punching system

Machine adopt hydraulic after cutting

Punching mould: Cr12 HREC58-62

Punching distance is adjustable by computer

10: Size of machine: About 10m*1.5m*1.2m (L x W x H) need one 40GP container

11: Color: Blue (it is also can change base on customer request)

12: Cutting:

(1)Machine adopt hydraulic after cutting

(2)Cutting after forming: Cut the sheet after roll forming to required length

(3)Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

(4)Material of blade: D2with heat treatment total 3 cutters

(5)Length measuring: Automatic length measuring

(6)Tolerance of length: 3m +/- 1.5mm

13: Base on customer request, this machine should be include cooling system for roll forming parts. So in hot air temperature such cooling system can protect the rollers.

Water pump: 1.5KW

Spout: About 5-6 pieces (it is base on final design)

Water box which can make water can circulate working: One piece

B. Uncoiler

Dimensions: 1700mm*1000mm*800mm

Width of feeding: 600mm

Capability: 5 Ton

Bound of expand &fight: 450mm_550mm

Mode of expand &fight: Inner expand &fight by manual

Way of feeding: Manual

C: Control panel Panasonic

(1)Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

(2)Automatic length measurement:

(3)Automatic quantity measurement

(4)Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved

(5)Length inaccuracy can be amended easily.

(6). Control panel: Button-type switch and touch screen

(7)Unit of length: Millimeter (switched on the control panel)

D: Hydraulic station

1: Hydraulic station power: 5.5kw

2: Hydraulic pressure: 20Mpa

E: Manual out table:

(1)Jointed by 60mm*40mm tube

(2)Size: 1.0m long*0.8mwide*0.6-1mhigh

(3)One out table with two support roller

Delivery

About Saibo

Saibo Science & Technology - 20 Years Experience Manufacturer in Developing and Exporting.Zhangjiagang City Saibo Science & Technology Co., Ltd. is a professional manufacturer specializing in the developing and exporting of different kind of high speed roll forming machine, Main use of our roll forming machine is for Solar Structures, PEB project and also for Cable tray, Guard Rail, Roofing Sheets, Floor Decking and all of the different kind purlin/channel which makes from GI/PPGI/PPGL/Aluminium/Aluminium alloy/SS . Our company, which is located in Zhangjiagang city, Jiangsu province, near Shanghai City with superior geographic position and convenient transportation.

We engaged in the steel structure industry in 20 years and devoted to developing some steel structure machines with professional technology and reasonable price, we supply the best machines for our new and regular customers. All of our technology team and marketing person all more than 10 years working. In particular, we are a leading exporter in the field of steel structure construction and can provide professional service, high quality, through design, and installation. Our goal is" future by heartiness, faith leads to the world".

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in Saibo Machinery.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark registration, etc.