Hard Chrome Electroplating Equipment Factory Copper Nickel Plating Machine

Junan Tongda Electronic Equipment Factory- After-sales Service:Yes

- Voltage:380V

- Automatic Grade:Portable

- Warranty:1 Year

- Certification:GS, CE, ISO, Co, Form E, Form F and etc.

- Application:Plating on Ss, Metal, Steel, Aluminum, Brass

Base Info

- Model NO.:TD-H

- Usage:Zinc, Nickel, Chrome, Decorative Chrome

- Coating:Copper, Brass Siliver, Gold, Tin and etc

- Model:Portable, Manual, Semi-Automatic, Full-Automatic

- Material:PP , PVC , Ss Plate Welding

- Portable:The Most Simple, Cheap

- Manual:Cheapest Standard Plating Line

- Semi-Automatic:Control by Remote for Labor

- Full-Automatic:Controlled by PLC Programee

- Pre-Treatment Machine:Polishing Machine, Virbarting Machine

- Pre-Treatment Porcess:Ultrasonic , Electronic ,Heating Oil Remove

- Extranl Equipment:Rectifier, Filter, Water Chiller

- After-Treatment Machine:Hot Rinse, Dry Machine, Oven

- Auxiliary Equipment:Di Water Machine

- Crane Lifting:Manual, Automatic, Electronic Hoist

- Transport Package:Plywood Packaged; Shipping by Sea

- Specification:Customized

- Trademark:TONGDA

- Origin:Linyi City Shandong Province

- HS Code:8543300090

- Production Capacity:5-10 Sets Per Month

Description

1. Material : 15mm PP(Polypropylene) / PVC(Polyvinyl chloride) plate

2. PP/PVC plating tank

3. Hangers (For the Rack/hang plating line):

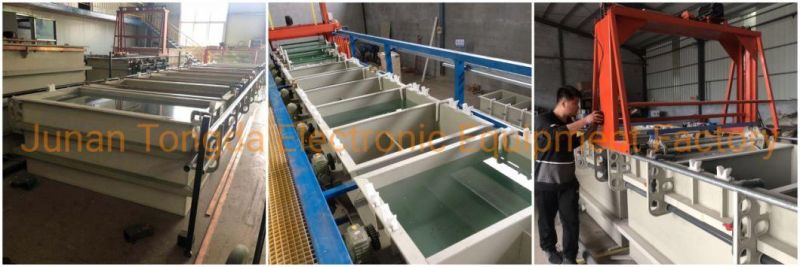

BEFORE DILIVERY:

We will assemble all tanks , install lifting crane , and run the machine to test .

Then we could check all parts well , making sure that the machine could run well when our client receive the machine .

In addition, we will make a Loading List as well . On the one hand , our people could clear all items when they Load . On the other hand , it will be helpful for our clients to check and confirm all parts when they receive the machine .

PACKAGE & DELIVERY

Package mode : by plywood or shipping by container directly .

Shipping : Ocean shipping

Lead time : 30-35 working days

FACROTY AND SERVICE:

This is our factory JUNAN TONGDA ELECTRONIC EQUIPMENT FACTORY which lie in Junan County , Linyi City ,

Shandong province . We are professional electroplating equipment manufacturer , zinc , nickel , chrome , copper, gold and etc.

plating equipment , welcome your inquiry .

1. We use 15 mm PP (polypropylene)/PVC (polyvinyl chloride) to make tanks . ( Also could accept customized )

But actually , we also do survey on our market ,we found that most of suppliers used 10-12 mm PP plate to make tanks . We have the confident of our quality of tanks . It's more strong , and could use for a long time .

2. As manufacturer : We could give you a affordable price as well .

and provide lifelong technology supports , online supports etc.

And we warmly welcome you come our city to have a visit .

3. Free parts as gift

1 year warranty

Lifelong technology supports

4. Advanced technology

We have more than 13years manufacture experience , More than 80% of high-quality employees have many years of production technology experience

5. Multiple Quality Control

Double testing of semi-finished and finished products in the production process to maximize the quality of all cleaning machine.

6. Independent research and innovation

1) Cooperate with major R&D institutions to develop innovative products in response to market demand .

2) Independent research and development, we will create exclusive cleaning equipment according to the special needs of customers to meet the customization needs of customers.

WELL , ABOVE ARE THE DETAILS WHAT I WANT TO TELL YOU , OUR FACTORY , OUR COMPANY , OUR EQUIPMENT , OUR SERVICE , THIS IS A PROFESSIONAL TEAM , WELCOME YOUR INQUIRY .

AWAIT YOUR KINDLY INFORMATION !!!

BEST WISHES TO YOU AND YOUR FAMILY !!

THANK YOU !