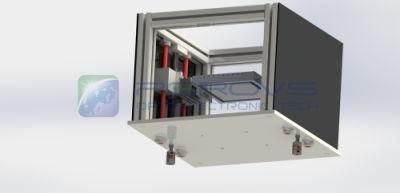

Coating Machine in Vacuum Environment

Hangzhou Zhongneng Photoelectricity Technology Co., Ltd.- Warranty:1 Year

- Condition:New

- Certification:ISO9001

- Customized:Customized

- Material:Metal

- Application:Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Transport Package:Wooden Box Shockproof

- Specification:500-900kg

- Trademark:PEROVS

- Origin:Hangzhou

Description

Basic Info.

Transport Package Wooden Box Shockproof Specification 500-900kg Trademark PEROVS Origin HangzhouProduct Description

Vacuum film formationVacuum film forming system consists of

1) vacuum pumping system, including vacuum pump and pipeline valve set;

2) substrate carrier and vacuum leveling plate;

3) up and down moving leveling table moving parts;

4) shell aesthetic parts;

5) vacuum pumping system including digital display vacuum degree display and electric control button of moving parts.

1.Composition of vacuum film forming system

Vacuum film forming system consists of 1) vacuum pumping system, including vacuum pump and pipeline valve set; 2) substrate carrier and vacuum leveling plate; 3) up and down moving leveling table moving parts; 4) shell aesthetic parts; 5) vacuum pumping system including digital display vacuum degree display and electric control button of moving parts.

2.Introduction to the application of vacuum film forming system

The vacuum film forming system is used to make dry films after wet film production such as coating/spin coating.

It is operated by placing the wet film on the substrate table of the system. The suction hood and suction plate are lowered to the effective position by the electric control button and then a closed environment is created for the subsequent placement of the substrate to be formed. After making sure the sealing O-rings and silicone gaskets are in the pressed position, the vacuum pumping system is turned on. The system consists of a vacuum pump, a valve train and a nitrogen MFC. The vacuum level can be created and maintained for a specified period of time.

When the required vacuum level is reached and guaranteed for a certain time. The inlet valve opens and dry nitrogen is fed into the small chamber. The suction hood and the air leveling plate rise. The substrate can be removed. The dry film is formed.