Steel Aluminum 914-610 K Span Large Span Curve Furring Channel Roll Forming Machine

Taicang Global Machinery Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:Automation

- Certification:CE

- Warranty:12 Months

Base Info

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Material Thickness:0.6 - 1.5 mm

- Production Speed:12 - 15 M,Min

- Roller Station:About 17 stations

- Main Motor Power:11KW

- Electric Control:PLC

- Transport Package:Wood Box

- Trademark:TGMCO

- Origin:China

- HS Code:8455221000

- Production Capacity:50 Sets,Year

Description

Basic Info.

Customized Customized Advantage Use Widely Condition New Material Thickness 0.6 - 1.5 mm Production Speed 12 - 15 M/Min Roller Station About 17 stations Main Motor Power 11KW Electric Control PLC Transport Package Wood Box Trademark TGMCO Origin China HS Code 8455221000 Production Capacity 50 Sets/YearProduct Description

Welcome to Taicang Global Machinery Co., Ltd

https://global-machinery1.en.made-in-china.com/

At Global Machinery, we provide Tube Mill, Roll Forming Machine, Slitting & Cut to length Line and corresponding components, and meet your customized requirements. Contact us right now!

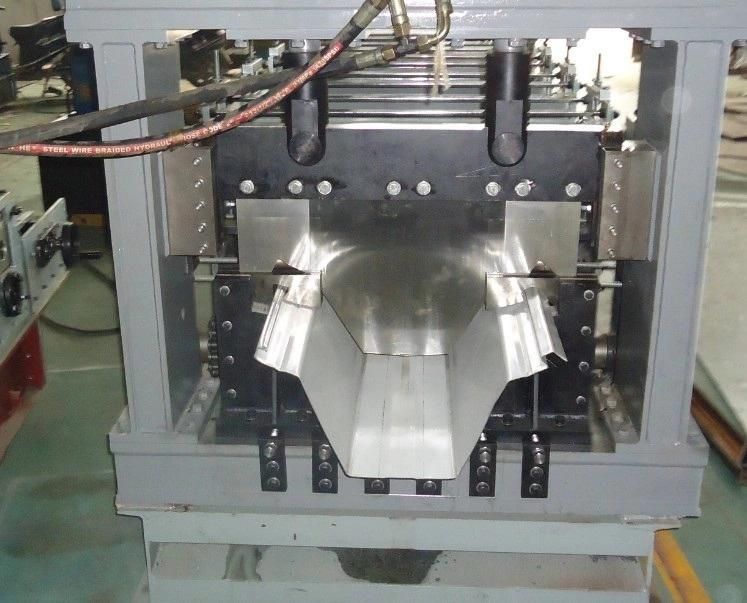

Main Specification

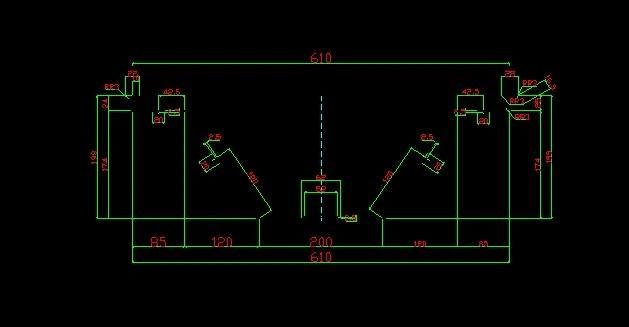

| Coil Width | 914 mm |

| Thickness of Color Steel Sheet | 0.6 - 1.5 mm |

| Output Speed | 12 - 15 m/min |

| Rolling Station | 15 Station |

| Electical Contral | PLC |

| Tolerance | 3m±1.5mm |

1. Coil width: 914mm

2. Output speed: 12 - 15m/min

3. Coil thickness: 0.6 - 1.5mm

4. Tolerance: 3m±1.5mm

5. Roller station: 15 stations

6. Main motor power: 11kw

7. Hydraulic oil pump motor: 5.5kw

8. The pressure of hydraulic: 12Mpa

9. Curving machine power: 5kw+1.5kw (two), Locking machine power: 0.85kw

10. Frequency inverter: Panasonic

11. Computer control system, PLC control length, encoder: Omron

12.Diameter of roller: Ф75

13. Material of roller: Gcr15

14. Material of cutter: Cr12Mov, heat treatment HRC 58 - 62, chrome coating

15.Transmission type: 1 inch double chain drive

16. Main machine dimension: 8.5m*1.4m*1.4m

17. Material of blade: GCR12 with heat treatment

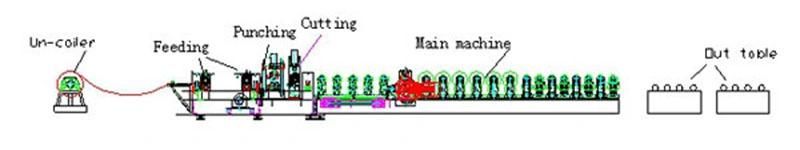

Flow Chart

Certificate

FAQ

1) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided). We have cooperated with many customers all over the world with high market reputation, no worries.

2) Q: How to choose the Tube Mill Line?

A: You have to inform us following details:

- The pipe material

- Round pipe range

- Square pipe range

- Rectangle pipe range

- Wall thickness range

- The pipe usage

3) Q: How to choose the Roll Forming Machine?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil weight

- Cutting type

- Profiles drawings

- Other special attention

4) Q: How to choose the Slitting Line & Cut to Length line?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil width

- Coil weight

- Finished sizes

- Other special attention

55) Q: Where is the nearest airport to your company?

A: Shanghai Putong or Hongqiao Airport.

6) Q: How about your service?

A: Before sales:

- Technical Support: TGMCO will provide detailed technical information such as technical & commercial offer, machine photos, running video, layout, operation manual, and show you working machines in our factory.

- Apply Visa: TGMCO will provide officially invitation letter to apply Visa in china embassy as authority procedures and requirements.

After sales: TGMCO provides comprehensive After Sales Support and Service to meet our customer need.

- Drawings: Provide the foundation drawing, electric scheme and wiring diagram, hydraulic drawing, pneumatic & electric pipeline drawing and other drawings requested by customer.

- Installation and commissioning: TGMCO will send our technicians to customer's workshop for supervision of installation and commission

Training of Customers' technician/workers during commission

- Breakdown Support: We offer 1 year warranty service for main crucial components except consumables

Inform immediate technical assistance and advice to customer by phone or e-mail.

Skilled and experienced engineers are capable of dealing with any type of breakdowns.

Technical service work performed in Customer's site if required.

Urgently supply mechanical or electronic components.

Fast supply of spare parts and wearing parts to cover foreseeable requirements

Packing & Delivery

Not only the Good Machine, but also the Most Attentive Service

Integrity Solution & Turnkey Project

Creat the Value of Steel