Compact Busbar Housing Saw Machine, Sandwich Busduct Profile Shearing Machine

Suzhou Kiande Electric Co., Ltd.- After-sales Service:24-Hour Online Service

- Warranty:1 Year

- Customized:Customized

- Layout:Vertical

- Cutting Material:Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

- Automatic Grade:Semi-Automatic

Base Info

- Model NO.:KDEQ-02-081

- Power Source:Hydraulic Pressure

- Cutting Mode:Saw Cutting

- Dimension:12000mmx1500mmx1360mm

- Transport Package:Plywood Case

- Specification:800mm*800mm*1700mm

- Trademark:Kiande

- Origin:China

- HS Code:8461500090

- Production Capacity:10 Set Per Month

Description

Basic Info.

Model NO. KDEQ-02-081 Power Source Hydraulic Pressure Cutting Mode Saw Cutting Dimension 12000mmx1500mmx1360mm Transport Package Plywood Case Specification 800mm*800mm*1700mm Trademark Kiande Origin China HS Code 8461500090 Production Capacity 10 Set Per MonthProduct Description

Busbar profile cutting machine, busbar housing shearing machine| Item | Parameters |

| Cutting angle | 45°/ 90° |

| Max. sawing width | 300/300/400/600/680mm |

| Max sawing height | 125/155/220/340/460mm |

| Sawing capacity; round bar | 120/140/220/310/420mm |

| Sawing capacity; square tube | 110*110mm; 130*130mm; 190*190mm; 280*280mm; 400*400mm |

| Main motor power | 4.0/4.0/5.5/7.5/11KW |

| Blade size | Φ355-455mm; Φ355-500mm; Φ355-610mm; Φ355-850mm; Φ500-1200mm |

| Spindle speed | 3600/2850/2200/1950/1000rpm |

| The height of the worktable | 850/850/920/1050/1380mm |

| Required air pressure | 5-8kg/cm2 |

We are the company specialized in busbar machine.Busbar machine means busbar production machine or busbar processing machine including mylar sleeve forming machine, busbar assembly machine, busbar riveting machine, busbar testing & inspection machine, busbar packing machine and busbar conveying machine. If you want to know how we use the machine to assemble the busbar, please kindly get the referenced pictures as below.

Step 1 Prepare all busbar finished components

Step 2 Use related busbar machines to process the busbar

Busbar machine copper processing

Need Kiande's busbar gas-hydraulic copper bar punching machine(This is one-time punching forming. In the market, some busbar manufacturer buys three-in-one busbar machine to bend and punch copper or aluminum bar. As the bar experiences many procedures, the accuracy is not good which will cause the phase distance too small to cause the short circuit.)

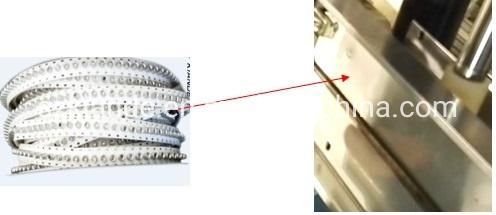

Busbar machine mylar sleeve processing machine polyester film forming machine

Need Kiande's mylar/polyester film forming machine. In the market, some busbar manufacturer requests workers to wrap the bar manually. Different workers have different workmanship. If employer meets the inexperienced workers, the wrapping part will have some gaps which will cause the short circuit.

Busbar machine busbar accessory 3M insulation film Conductor(Copper bar/Aluminum bar) end wrapping

Busbar machine busbar accessory Aluminum profile capped casting capped end / Busbar support

Busbar machine Busbar riveting machine

Busbar machine busbar accessory rivet the rivet is to connect the profiles instead of bolts more stable and strengthen