Self-Lock Roof Sheet Roll Roof Sheet Roll Standing Seam Tile Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:Customized

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Auto:Fully Automatic

- Feeding Material:Metal Coil

- Feeding Width:400,500mm

- Feeding Thickness:0.25-0.7mm Thickness

- Production Speed:4-6m,Min

- Roll Forming Speed:8-12m,Min

- Control system:PLC Computer Control with Inverter

- Size:6500mm*1500mm*1500mm

- Weight:3.2 Tons

- Transport Package:Waterproof Package

- Specification:CE SGS ISO

- Trademark:DIXIN

- Origin:China, Hebei

- HS Code:84552210

- Production Capacity:50 Sets Per Month

Description

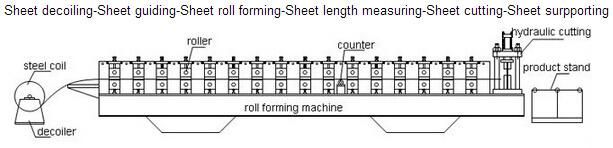

Working flow

Manual decoiler

It is passive type could load coil by expend the blots fix at coil inner diameter. It's easy to operate and economical solution.

Guiding device

Adopt guiding bar and sliding block to control the width and position of the steel sheet. The coil is guided in the correct position and passed to the roll forming system. Can adjust the guiding bar with loosing the fixing bolts to feed sheet in right position. It's fixed structure to make sure can not move easily.

Roll Forming System:

Roll forming system consist of machine frame, transmission system, electrical motor and roll forming system.

A. Machine frame adopts welding structure with shot blasting and painting treatment

B. All rollers material adopt high quality No. 45 steel, with hard chrome coated on surface, all treatment by full CNC machines, to make sure the rollers with good rigidity and precision, and form perfect roofing sheet as per design.

C. All rolling shafts are made by high quality No. 45 steel with quench and temper treatment, so the shafts with good rigidity which could use for long tern without deformation.

D. Rolling shafting supporting structure type is steel wall and welded with the basement together to have rigidity.

E. Cycloidal pin gear speed reducer motor driven, the back/forward roller driven by chain, part of upper/lower rollers driven by gear

F. Adjust the screw bar manually to adjust the distance between upper/lower rollers for difference thickness of sheet.

(Attention: all rolling system has adjusted in our company as a perfect situation, we don't suggest to adjust the rollers at random, if necessary, should adjust by a experienced technician or after train by our engineer. Otherwise will cause the machine can not form a good profile

Cutting device

A. Adopts post cutting, the cutting blade material is Cr12 with quenched treatment, after cutting, there is no material wasted.

B. Adopts welded frame for good rigidity.

C. The cutting action is droved by the power from hydraulic station which guarantees the procession of the cutting and low noisy, long life.

Hydraulic System

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job.

The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves.

Power of the oil pump: 3kw

Hydraulic oil: 40#

Cangzhou Dixin Roll Forming Machine Co.,Ltd,Our company is the professional and leading manufacture,can manufacture ,design,installation and debug various roll forming machines and metal processing sheet equipments ,which produce metal roof wall panel,glazed roof tile , CZ steel purlin,floor desking,roof ridge cap,sandwich panel ,roof rtruss,shutter panel,shutter slat,door frame, guardrail ,and metal sheet uncoiler ,bending ,slitting,cutting,flattening,punching,crimpingl. especially can design machine according to customer's request.

Packaging & Shipping

1.Packaging Details:Nude,with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

2.Port:TIANJIN XINGANG PortLead .

3.Time: Shipped in 35 days after payment.

Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.

1. Free technical support and free accessories supply.

2. Engineer available to service machinery overseas.

3. One year warranty is provided.

4. Long life technical guidance for free.

5. We always offer technical support, quick response, all your inquire will be replied in 24 hours.

FAQ

Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.

Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What's your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV(Alibaba) Certificate.

Q5. How about the after-sale service?

A5: We provide 12 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Q6. If I am in Beijing,or Shanghai ,how to visit your company?

A6: 1)Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

2)Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.