Multi Color Coated Painting/Coating Line Coating Machinery for The Meta Roof Sheet

Qingzhou Reachfly Environment Technology Co., Ltd.- After-sales Service:Yes

- Warranty:1 Year

- Type:Coating Production Line

- Coating:Coil Coating

- Substrate:Steel

- Certification:ISO

Base Info

- Model NO.:REACHFLY 003

- Condition:New

- Width of Strip Steel:600-1650mm

- Thickness of Strip Steel:0.12-1.5mm

- Outer Diameter of Steel Coil:φ;800-2000mm

- Process Speed:25-180m,Min

- Material of Base Plate:Ci,Gi,Gl

- Coating Type:Coil Coating

- Power:250~550kw

- Weight:450000(Kg)

- Thickness of Coating:Regulated as Required

- Thickness of Printing Layer:≤25μm

- Supply Ability:20 Set,Sets Per Year

- Voltage:380V

- Dimension(L*W*H):Customized

- Core Components:PLC, Engine

- Delivery Time:5 Month

- Transport Package:Standard Seaworthy Package

- Specification:Customized

- Trademark:Reachfly

- Origin:China

- HS Code:8479819000

- Production Capacity:20 Sets Per Year

Description

Chemical coaterTOP 3 g-5g/m2 Water base BOTTOM 3 g-5g/m2 Water base

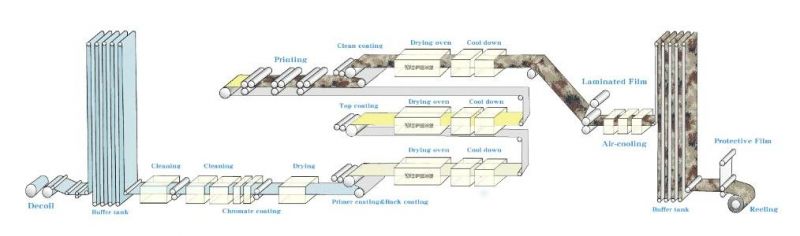

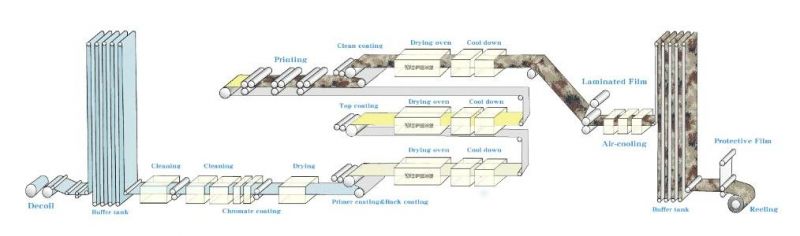

4. Processing Procedure:

_______________________________________________________________________________

Decoiler------Gripper------Clipper------Sewing Machine------Burr Masher------Tension Machine------Entry Looped------Tension

Machine------Soak Degreasing------Drying Machine------Defatted Liquid Spray------Brush Machine------Drying Machine--------

Drying Machine------Water Cleaning------Brush Machine------Drying Machine------Soak water------Steam dry oven------Passiv

ating machine------Passivating dry oven------Rectify deviation machine------Tension Machine------Bottom coating machine---

---Primary coating dry oven------Recetify deviation machine------Tension machine------Printing machine------Finishing machin

e------finishing coating dry oven------cooling system------rectify deviation machine------water cooling------drying machine------

Tension machine------Exits looped------Tension machine------Film covering machine------Clipper------Recoiler

5. Customer Visit:

5. Customer Visit:

_______________________________________________________________________________

6. Delivery:

_______________________________________________________________________________

4. Processing Procedure:

_______________________________________________________________________________

Decoiler------Gripper------Clipper------Sewing Machine------Burr Masher------Tension Machine------Entry Looped------Tension

Machine------Soak Degreasing------Drying Machine------Defatted Liquid Spray------Brush Machine------Drying Machine--------

Drying Machine------Water Cleaning------Brush Machine------Drying Machine------Soak water------Steam dry oven------Passiv

ating machine------Passivating dry oven------Rectify deviation machine------Tension Machine------Bottom coating machine---

---Primary coating dry oven------Recetify deviation machine------Tension machine------Printing machine------Finishing machin

e------finishing coating dry oven------cooling system------rectify deviation machine------water cooling------drying machine------

Tension machine------Exits looped------Tension machine------Film covering machine------Clipper------Recoiler

5. Customer Visit:

5. Customer Visit:_______________________________________________________________________________

6. Delivery:

_______________________________________________________________________________