Molybdenum Base Alloy Plug Used for Manufacturing Seamless Stainless Steel Pipes and Tubes

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Stainless Steel,Alloy Steel

- Transport Package:Woodern Case

- Specification:more than 96.5% moly

- Trademark:FANGLE

- Origin:China

- Production Capacity:40000tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Stainless Steel,Alloy Steel Transport Package Woodern Case Specification more than 96.5% moly Trademark FANGLE Origin China Production Capacity 40000tons/YearProduct Description

Molybdenum Base Alloy Plug Used for Manufacturing Seamless Alloy Steel Pipes

Description

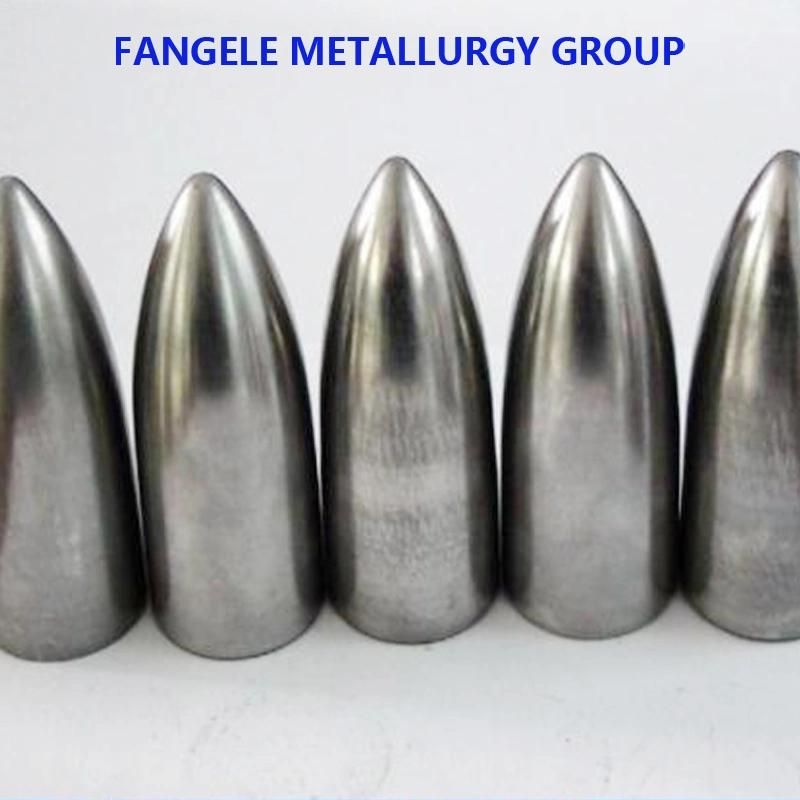

Molybdenum plug is made of molybdenum titanium zirconium carbon alloy, which is used to produce the mandrel plugs for seamless steel tube piercer.

Specifications

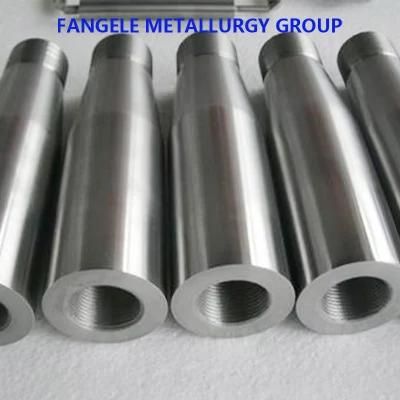

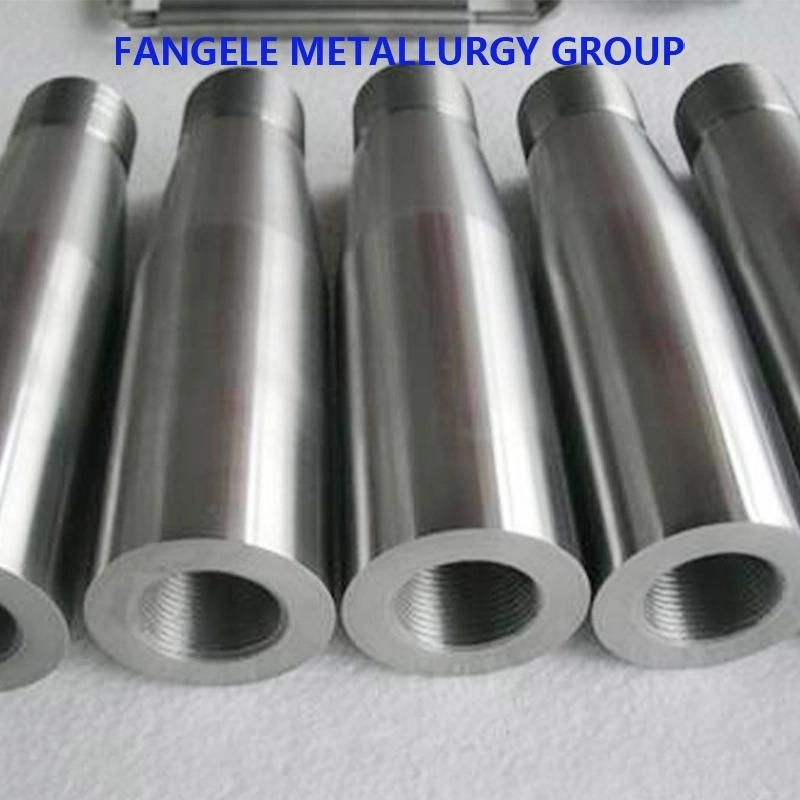

Product diameter specifications: Φ 20-300 mm, and different processing manufacture according to your drawings.

Usage

For piericing seamless steel tube, such as stainless steel, steel, high temperature alloy steel, molybdenum and other special parts.It is mainly used for piericing seamless steel tubes such as stainless steel, brazing steel, bearing steel and high temperature alloy steel.

Chemical composition

It's the molybdenum powder plus the other given element.

China standard chemistry: Ti 1.0-2.0%, Zr 0.1-0.5%,C 0.1-0.5%. Balance Moly and other alloy elements.

Features

High strength at high temperature, good oxidation resistance at high temperature, long service life, corrosion resistance and not easy to make glass coloring.

Molybdenum plug production process

First, molybdenum powder FMO-1 raw material was used to add rare earth materials, and then after mixing, molding, shape processing, high temperature sintering and other processing processes, the finished product density ≥9.4g/cm3.

Customer Visit