Cold Crucible Vacuum Levitation Melting Furnace with Magnetic Stirring Function

Zhengzhou CY Scientific Instrument Co., Ltd.- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Semi-Automatic

- Certification:CE, TUV

- Type:Special Casting

Base Info

- Model NO.:EQ-FMF-65

- Output Frequency:20-50 kHz

- Max. Load: 250 G of Ti

- Water Flow Rate:6~8m³,H

- Working Temperature:Max. 1800ºC

- Vacuum Chamber:Stainless Steel

- Warranty:One Year

- Transport Package:Wooden Box

- Specification:65KW

- Trademark:CY

- Origin:Zhengzhou, China

- HS Code:85141090

- Production Capacity:310 Sets Per Month

Description

Basic Info.

Model NO. EQ-FMF-65 Output Frequency 20-50 kHz Max. Load 250 G of Ti Water Flow Rate 6~8m³/H Working Temperature Max. 1800ºC Vacuum Chamber Stainless Steel Warranty One Year Transport Package Wooden Box Specification 65KW Trademark CY Origin Zhengzhou, China HS Code 85141090 Production Capacity 310 Sets Per MonthProduct Description

Cold Crucible Vacuum Levitation Melting Furnace (65KW, 250g Ti Max.) with Magnetic Stirring Function - EQ-FMF-65EQ-FMF-65 is floor-stand Cold Crucible Vacuum Levitation-Melting system for exploring new generation magnetic alloy and metallic materials. With the powerful 65KW induction heater, the system can effectively heat metallic samples upto 250g (Ti), 1800C max. The special designed water-cool copper crucible in the SS vacuum chamber is contamination free to charge material benefits from the non-contact levitation heating. Strong electromagnetic stirring also promotes excellent thermal and chemical homogenization of the melt.

| Induction Heater | Working Voltage: 220VAC +/-10%, Three phases, 50/ 60 Hz. Output Frequency: 20-50 kHz Max. Output Power: 65KW |

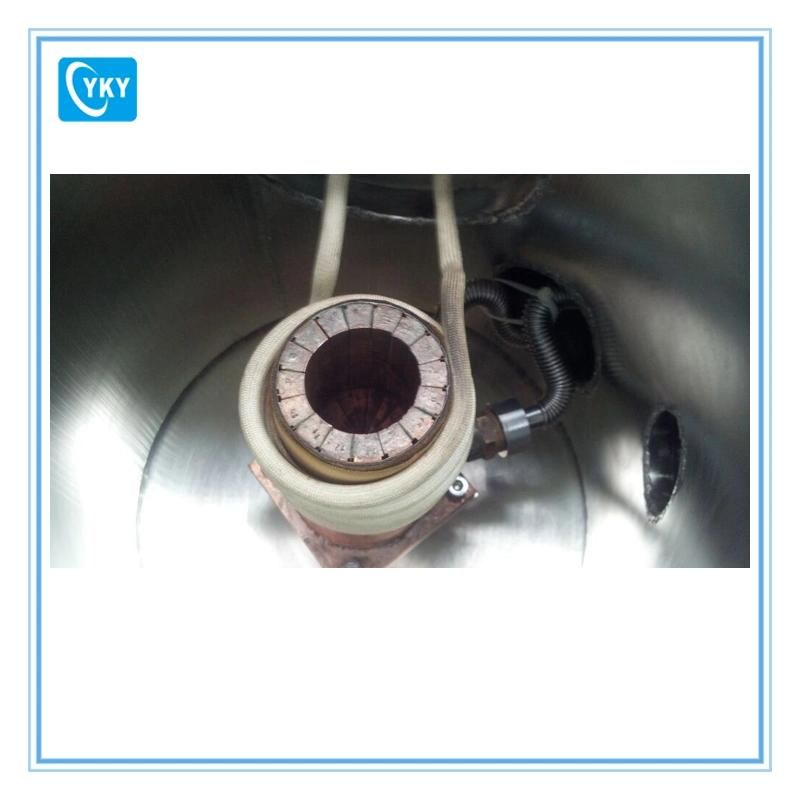

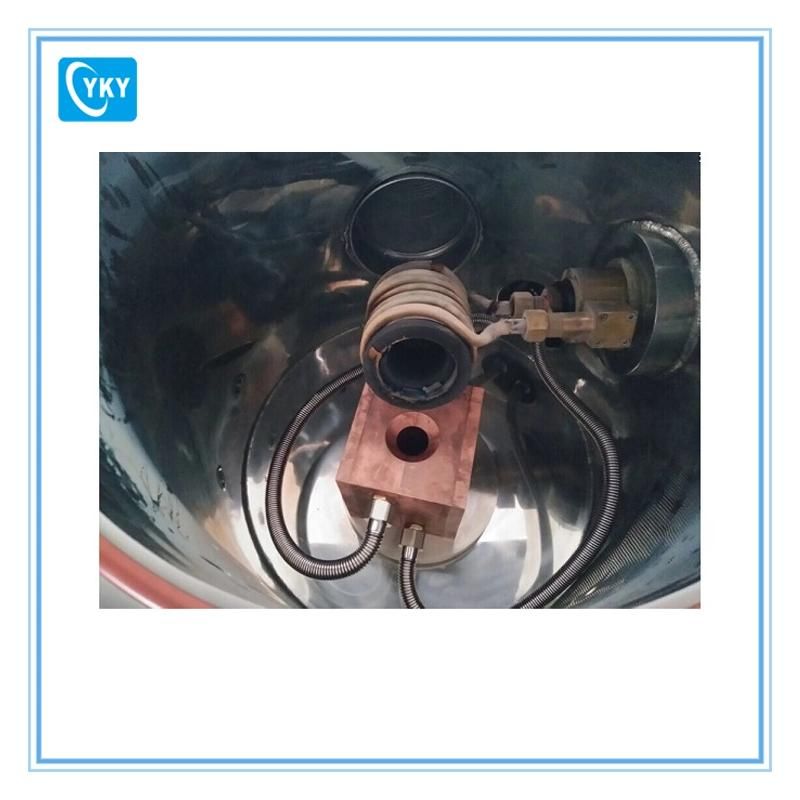

| Copper Crucible | Refractory-free induction melting under vacuum or controlled gas atmosphere eliminates the possibility of contamination from the ceramic crucibles. The magnetic field produced by the coil intensely stirs the liquid pool and promotes a very homogeneous melt. Dimensions:50 mm(ID) x 100 mm depth The copper cold crucible is made up of 16 water-cooled segments which has joint connection to the bottom. Max. Load: 250 g of Ti , 140g Fe Water flow rate: 6~8m³/H (100~133.3L/m) |

| Optional | A vacuum charger adding port is available upon request at extra cost Tilltable coil and crucible for casting sample into a water cold coopermold is available at the extra cost |

| Working Temperature | Max. 1800ºC Infrared pyrometer for temperature measurement |

| Vacuum Chamber and Lid | 304 Stainless steel made chamber with double layer water cooling jacket ensures low surface temperature < 40ºC SS flange with quartz observation window allows the user monitor the crucible melt during the process. Tinted observation glass is integrated for eye protection purpose. |

| Vacuum Pump | One turbo pumping system (620L/s) with two stage backing pump (6L/s) are included Rotary and turbo pumps are integrated in the bottom of machine casing Pirani and Ionized Gauge are installed for vacuum measurement. Max. achievable vacuum level: 6.67x0^-4 Pa (RT, unloaded) |

| Water Chiller and Gas requirement (Not included) | Please consider using tap water or water chiller (flow rate >100L/min) |

| Warranty | One Year limited warranty with lifetime support |