Factory Supply DSP-100kw Digital Induction Heater for Hot Forging, Annealing, Tempering, Quenching, Melting

Foshan Sinfor Electro-Machanical Equipment Co., Ltd.- After-sales Service:24hours*7days Free Parts

- Warranty:18months Delivering, 12months Receiving

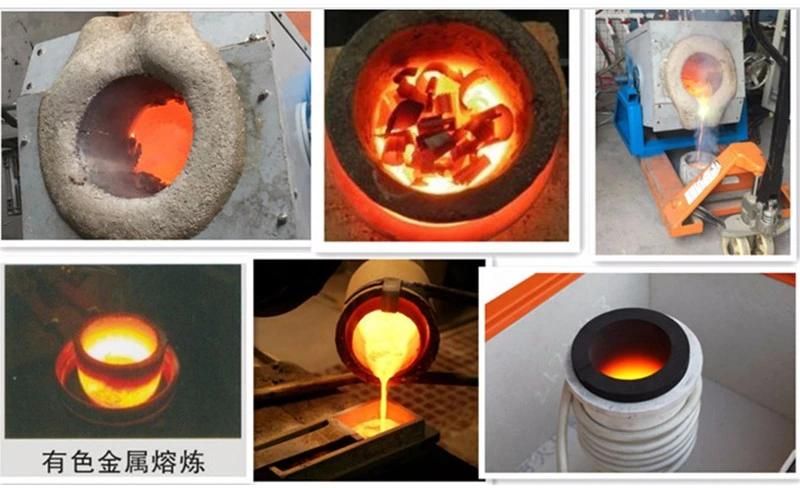

- Application:Heating, Quenching, Forging, Melting, Welding

- Power:100kw

- Frequency:10-40kHz

- Input Current:150A

Base Info

- Model NO.:DSP-100KW

- Working Voltage:380V,415V,440V,480V 50-60Hz

- Main Machine Size:800*600*1000mm

- Transformer Size:650*450*600mm

- Weight:Mainparts:155kg Transformer:127kg

- Work Power:3*380V,415V,440V,480V 50-60Hz

- Display:Digital Display

- Front Panel:Touch Screen

- IGBT:Infineon

- Working Way:Manual, Temperature,Timer, Section

- Time:1-9999s

- Protection Level:Over Current, Over Voltage , Under Voltage, Lack W

- Transport Package:Wooden Box

- Specification:CE, SGS, ISO

- Trademark:ORD

- Origin:China

- HS Code:8514400090

- Production Capacity:10, 000sets

Description

Basic Info.

Model NO. DSP-100KW Working Voltage 380V/415V/440V/480V 50-60Hz Main Machine Size 800*600*1000mm Transformer Size 650*450*600mm Weight Mainparts:155kg Transformer:127kg Work Power 3*380V/415V/440V/480V 50-60Hz Display Digital Display Front Panel Touch Screen IGBT Infineon Working Way Manual, Temperature,Timer, Section Time 1-9999s Protection Level Over Current, Over Voltage , Under Voltage, Lack W Transport Package Wooden Box Specification CE, SGS, ISO Trademark ORD Origin China HS Code 8514400090 Production Capacity 10, 000setsProduct Description

DSP-100KW Factory Supply Digital Induction Heating Machine

Advantage:

1 More than 22 years experience, stable and goods performance

2 CE certificated

3 Copperated with CHOW TAI FOOKS, Matsushita, Foxconn, Media, Gree and ZHIGAO Air conditioner.

4 Suitable for a large range, heating, quenching, forging, melting, solding and so on.

Main Characteristic:

1 Front Panel use the LCD Touch Screen, Key and Power Switch, all digital display, can use Switch Signal( Electrical frequency signal) to control the

machine start and stop, and control the power via PLC.(RS232 or RS485 is options).

Visual Human-computer Interface makes the operator feel more intimate and intuitive. Because of its abundant industrial interfaces, it has stronger andmore flexible matching ability with robots, various automation equipment and remoe control (unmanned) devices.

2 Induction Heating Machine have remote control function and adopt digital circuit control, power regulation can be adjusted from 0% to 100% resolution, and digital PID temperature control module can be configured to set the target temperature of workpiece (infrared temperature measurement or thermocouple temperature measurement) automatically. The accuracy of temperature control is + 1'C for power regulation in heating process.

3 There are 5 working model, manual, timer, Stop temperature, Constant temperarure, section heating model.

1) Manual, On and stop in the Switch

2 ) Timer, setting heating time, after reach the heating time, then stop.

Stop Temperature: Set the heating temperature that we need it, when the reach to the temperature that we need it, then stop the machine.

3) Constant Temperature: Adjust the heating power automatic to keep the same temperature to the workpiece.

4) Section Heating model, there are 8(S1-S8) options, each section can set the heating power, timer, temperature or constant temperarture, temperature or constant temperature just can choose any one. Power as 0 means no need to heat, put the paramater that you need to set, if not choose that functionthen show"--

5) There are 9 (P1-P9)programs, which can memorize 9 different workpiece in the machine, and select programs by clicking P(P1-P9). Can save much time if you have many workpiece in one machine, you can choose the programs (P1-P9) to fast working

| Type | DSP-100AB |

| Work Power | 3*380v/415v/440v/480v 50-60hz |

| The range of operating voltage | 340-430V AC |

| Output power | 100KW |

| Input current | 150A |

| Fluctuating frequency | 10-40khz |

| Timing (Heat time,Retain time,Cool time) | 1-9999S |

| The flow rate of cooling water | 0.15 Mpa 25L/Min |

| Water temperature protection point | 40centidegree |

| Duty cycle | 100% (40degree room temperature) |

| Weight | Mainparts:155Kg Transformer:127kg |

| Size | Main Parts:800*600*1000MM Transformer: 650*450*600MM |

1. recommend the most suitable machine for customers, according to their requirements.

2. Inquiry and consulting support.

3. Sample testing support.

4. View our Factory.

In-sale service:

1. Strictly manufacture the machine, according to relevant technical standards.

2. Take run test, according to relevant equipment test run regulations.

3. Strictly check up the machine, before delivery

4. Delivery on time.

After-sale service:

1. Warranty time: Within 18 months from the date of delivering, 12months from date of receiving.

2. Within warranty all parts are free for customer, any fault caused by non-artificial reason, any quality problems such as design, manufacture, or procedure occurs, We shall provide replacement parts after detecting the faults.

3. If any big quality problems occurs out of the guarantee period, we will send maintenance

technician to provide visiting service after checking with the customer and charge for a favorable price.

5. We will provide a lifetime cost price to the buyer with the materials and spare parts used in system operation, equipment maintenance.

6. The above mentioned are only basic aftersale service requirements,we will make more promises related to quality assurance and operation

guarantee.