Full Cover Screw Header Metal Forging Machine, Screw Bolt Threading Machine

Xuchang Huarui Machinery Co., Ltd.- After-sales Service:Lifelong Technical Support

- Type:Forging Operation

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:Automation

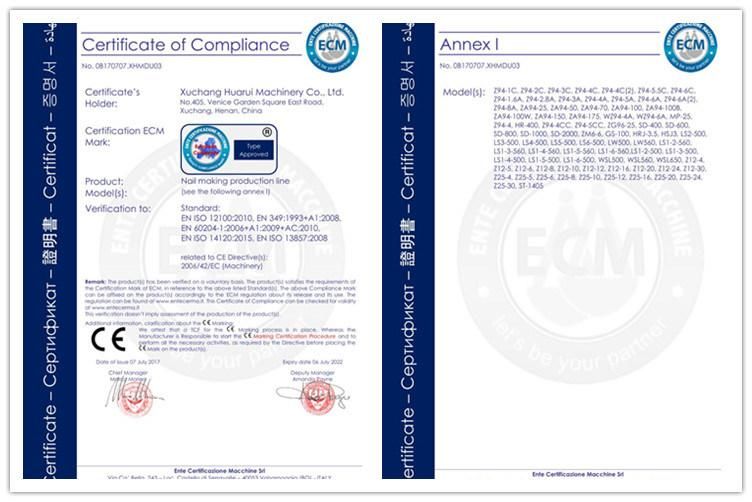

- Certification:CE

Base Info

- Model NO.:Screw cold header machine

- Warranty:2 Years

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Voltage:380V, Customized

- Power(W):0.75-15kw

- Weight:0.6t-11t

- Screw Diameter:3-14mm

- Screw Length:10-360mm

- Color:Green(or Customized)

- Transport Package:Sea Worthy Wooden Case or as Required

- Trademark:Huarui

- Origin:China

- Production Capacity:300 Sets,Month

Description

Basic Info.

Model NO. Screw cold header machine Warranty 2 Years Customized Customized Advantage Use Widely Condition New Voltage 380V/ Customized Power(W) 0.75-15kw Weight 0.6t-11t Screw Diameter 3-14mm Screw Length 10-360mm Color Green(or Customized) Transport Package Sea Worthy Wooden Case or as Required Trademark Huarui Origin China Production Capacity 300 Sets/MonthProduct Description

Screw/Bolt Making Machine, Thread Rolling Machine, Cold Heading Machine, Screw heading machine1. Automatic bolts making machine

This equipment adopts cold heading way to make the wire rod upsetting by double-click the whole mould form. Finished Feeding, straightening, cutting material, forming, discharging by one machine.

| Model | Max. Screw Dia (mm) | Max. Screw length (mm) | Capacity (pcs/min) | Motor (kw) | Weight (Ton) | Overall size (m) |

| M3-18A/B | 3 | 18 | 160-180 | 0.75/0.37 | 0.6 | 1.3*0.75*0.9 |

| M3-28A/B | 3 | 28 | 160-180 | 0.75/0.37 | 0.6 | 1.3*0.75*0.9 |

| M4-28B | 4 | 28 | 120-160 | 1.5/0.37 | 0.97 | 1.5*0.9*0.9 |

| M4-28D | 4.5 | 28 | 180-200 | 1.5/0.37 | 1.2 | 1.6*1*1.2 |

| M4-40B | 4 | 40 | 120-150 | 1.5/0.37 | 0.97 | 1.5*0.9*1 |

| M4-40D | 4.5 | 40 | 180-200 | 1.5/0.37 | 1.2 | 1.6*1.1*1.1 |

| M5-40B | 6 | 40 | 120-150 | 2.2/0.37 | 1.8 | 1.8*1.1*1.1 |

| M5-60B | 6 | 60 | 110-140 | 2.2/0.37 | 1.8 | 1.8*1.1*1.1 |

| M5-80B | 6 | 80 | 80-100 | 2.2/0.37 | 1.9 | 2*1.1*1.2 |

| M5-100B | 6 | 100 | 60-80 | 3/0.18 | 2.1 | 2.4*1.2*1.2 |

| M5-120B | 6 | 120 | 50-70 | 3.6/0.37 | 2.3 | 2.8*1.3*1.3 |

| M6-60B | 8 | 60 | 80-110 | 4/0.37 | 2.8 | 2.3*1.3*1.3 |

| M6-100B | 8 | 100 | 60-90 | 4/0.37 | 2.7 | 2.3*1.3*1.3 |

| M6-120B | 8 | 120 | 60-70 | 4/0.37 | 3 | 2.4*1.3*1.4 |

| M6-170B | 8 | 170 | 40-70 | 4/0.37 | 3.7 | 3*1.3*1.5 |

| M6-200B | 8 | 200 | 40-55 | 4/0.37 | 3.7 | 3*1.3*1.5 |

| M8-120B | 10 | 120 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.5*1.5 |

| M8-130B | 10 | 130 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.51.5 |

| M8-130C | 10 | 130 | 50-90 | 5.5/0.37 | 4.6 | 3.4*1.51.5 |

| M8-150C | 10 | 150 | 40-50 | 5.5/0.37 | 5 | 3.5*1.7*1.7 |

| M8-200B | 10 | 200 | 25-60 | 7.5/0.37 | 6 | 3.8*1.6*1.7 |

| M10-120B | 12 | 120 | 40-70 | 11/0.75 | 7 | 3.3*1.71.7 |

| M10-170C | 12 | 170 | 40-60 | 11/0.75 | 7.5 | 4.2*1.81.7 |

| M10-220C | 12 | 220 | 35-60 | 11/0.75 | 7.5 | 4.2*1.81.7 |

| M10-250C | 12 | 250 | 30-45 | 11/0.75 | 8.5 | 5*1.8*1.7 |

| M10-300C | 12 | 300 | 25-35 | 15/0.75 | 9 | 5*1.9*2.1 |

| M10-360C | 12 | 360 | 20-30 | 15/0.75 | 12 | 6.7*2*2.6 |

| M12-150C | 14 | 150 | 40-50 | 15/0.75 | 10 | 3.9*1.9*1.8 |

| M12-250C | 14 | 250 | 35-50 | 15/0.75 | 11 | 5.3*2.2*1.9 |

| M14-150C | 16 | 150 | 40-50 | 11/0.75 | 10 | 4.5*2.2*2.15 |

| M14-250C | 16 | 250 | 35-45 | 15/0.75 | 11 | 5*2.2*2.15 |

2. Full automatic thread rolling machine

This equipment adopts two thread profile thread rolling plate staggered 1/2 screw distance design, dead plate is fixed, movable plate equal to dead plate do straight line motion back and forth, when the work piece feed between two plates, movable plate move forward twist work piece, make its surface plastic deformation into thread.

Thread rolling machine is portable, flexible, high efficiency and has some irreplaceable advantages compared with similar equipment, avoid the limit of lathe, drill or hand tapping, save time, labor, not easy to rotten teeth, screw tap not easy to break off.

The machine is easy to operate, convenient to maintenance, which greatly decrease the technical requirements for workers.

| Model | Max. Screw Dia (mm) | Max. Screw length (mm) | Motor (kw) | Capacity (pcs/min) | Weight (Ton) | Overall size (m) |

| R3-20A | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

| R3-20B | M2.6 | 20 | 1.1 | 350 | 0.3 | 1.1*0.53*1.2 |

| R4-25A | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

| R4-25B | M4 | 25 | 1.5 | 320 | 0.45 | 1.3*0.63*1.32 |

| R4-40A | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

| R4-40B | M4 | 40 | 2.2/0.37 | 280 | 0.97 | 1.5*1.15*1.35 |

| R5-55B | M5 | 55 | 3+0.37 | 160 | 1.2 | 1.6*1.35*1.7 |

| R5-65A | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

| R5-65B | M5 | 65 | 3+0.37 | 130 | 1.3 | 1.75*1.4*1.65 |

| R6-60A | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

| R6-60B | M6 | 60 | 4/0.37 | 180 | 1.5 | 1.7*1.65*1.3 |

| R6-100B | M6 | 100 | 5.5+0.37 | 110 | 1.9 | 2.7*1.3*1.3 |

| R8-80B | M8 | 80 | 5.5/0.37 | 110 | 1.8 | 2.1*1.55*1.3 |

| R8-100B | M8 | 100 | 7.5+0.37 | 100 | 2.1 | 2.7*1.7*1.3 |

| R8-120B | M8 | 120 | 5.5 | 100 | 2.1 | 2.4*1.8*1.4 |

| R10-120B | M10 | 120 | 7.5 | 80 | 1.8 | 2.35*1.95*1.4 |

| R12-120B | M12 | 120 | 11 | 60 | 3 | 2.45*2*1.45 |

| R12-160B | M12 | 160 | 13 | 60 | 3 | 2.45*2*1.45 |

| R12-220B | M12 | 220 | 15 | 50 | 3.5 | 2.5*2*1.45 |

| R16-120B | M16 | 120 | 15 | 50 | 3.8 | 2.5*2.1*1.45 |

| R16-160B | M16 | 160 | 15 | 50 | 4 | 2.5*2.1*1.45 |

| R16-220B | M16 | 220 | 15 | 45 | 4.8 | 3.7*1.9*1.7 |

Detail pictures

Packing and delivery

After - sales service

1.All products purchased in our company are guaranteed to keep in good repair for two years. If quality problems happen in guarantee period, our company will maintain for free.

2.Before sending the machine, we will test and adjust, so you can use directly when you get it. Operation video & instruction will be sent to clients, to help them use the machines better.

3. Additionally, our company provides technical support and fittings for life. After-sales service isn't restricted by time and we will solve your problems in time. If you are caught in some problems when using our products, welcome to contact us at any time.

4. Any problems occur while using, professional advice will be offered.

5. All kinds of frequently used parts are supplied all the year round.

6. 24 hours on line service.

CE Certification

Customer visit

Any enquiry are welcome, please feel free to contact us.