Thick Steel Automation Machine Plates Straightening Straightener with Competitive Price

GUANGDONG RUIHUI INTELLIGENT TECHNOLOGY CO., LTD.- Type:Uncoiler Straightener Feeder

- Usage:Coiled Material Straightening

- Voltage:380V

- Automatic Grade:Automatic

- Principle:Large Deformation

- Certification:TUV, ISO9001, CE

Base Info

- Model NO.:MAC4-1300

- Warranty:12 Months

- Customized:Customized

- Condition:New

- Stock Width(mm):100-1300

- Stock Thickness(mm):0.6-8.0

- Line Speed(M/Min):16-24

- Coil Weight(Kg):10000

- Transport Package:Wooden Box

- Specification:3150*4700*3450

- Trademark:RUIHUI

- Origin:China, Dongguan

- HS Code:8462219000

- Production Capacity:10 Sets Per Month

Description

3 Phase 220V/380V/50HZOperating Air(Mpa) 0.49 0.49 0.49 0.49 0.49

Straigtening Performance:ModelMAC4-400 MAC4-600 MAC4-80 MAC4-1000 MAC4-1300 Stock Thickness

(mm) 0.6~1.3 400 600 800 1000 1300 2.0 2.3 2.5 1170 2.8 933 933 3.2 714 714 714 4.0 457 457 457 457 4.5 361 361 361 361 361 5.0 293 293 293 293 293 6.0 203 203 203 203 203

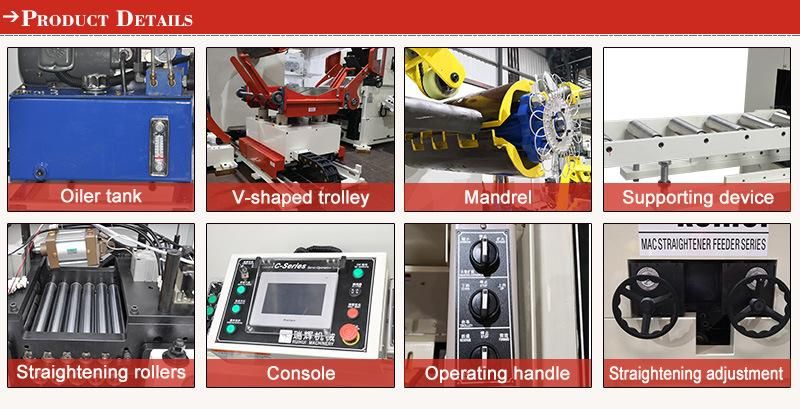

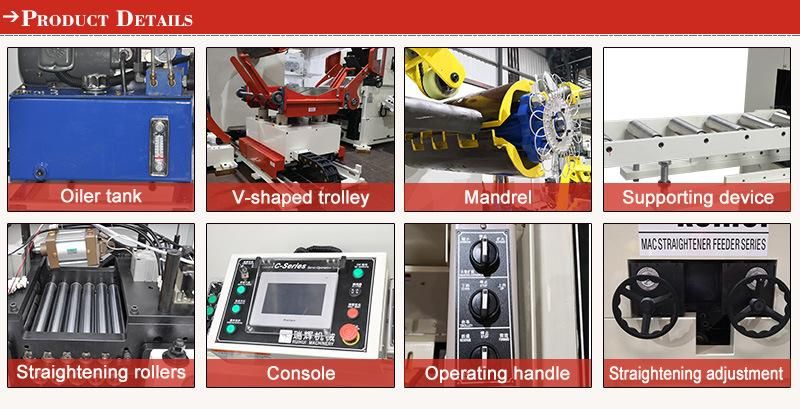

The three-in-one feeder is composed of three functions: rack, leveling, and feeding, and its loading, feeding, blocking, folding, leveling, feeding, and reloading are all controlled by one person on an independent console. The operation can be completed, which greatly saves labor, which effectively solves the problem of inconsistent leveling and feeding, and realizes the effect of high-speed leveling and feeding. At the same time, the overall appearance is strong and beautiful.

1. High-precision feeding: Jinzhide three-in-one feeder uses Mitsubishi PLC with Japanese imported servo motors and supporting drivers to achieve stable and high-precision feeding, with an accuracy of up to 0.01mm.

2. Save floor space and space: The three-in-one leveling feeder has the functions of discharging, leveling and feeding together. There is no need to equip the leveling machine and material rack. The main feature is space saving and reducing waiting area. Higher accuracy of feeding and leveling.

3. Convenient and fast loading and unloading: equipped with a loading trolley: the material is smoothly moved to the expansion and contraction structure of the uncoiler's main shaft, which is used to hold the material when uncoiling, so that the material belt can smoothly enter the leveling machine. (Optional)

Why choose us?

1st,We have a high level of technical research and development team;

2nd,We can provide the design and planning of the whole plant to realize the turnkey project;

3rd, our philosophy: quality is the social responsibility;

4th,our products have been recognized by the market, in the major automotive OEM, home appliance industry, hardware industry has been applied;

5th,We have a highly effective after-sales service team and get customer approval

Straigtening Performance:Model

(mm)

The three-in-one feeder is composed of three functions: rack, leveling, and feeding, and its loading, feeding, blocking, folding, leveling, feeding, and reloading are all controlled by one person on an independent console. The operation can be completed, which greatly saves labor, which effectively solves the problem of inconsistent leveling and feeding, and realizes the effect of high-speed leveling and feeding. At the same time, the overall appearance is strong and beautiful.

Three-in-one feeder Dongguan RUIHUI has an annual warranty of one year, you can buy it with peace of mind, and use it with confidence. After-sales service can be solved within 24 hours in nearby areas and within 48 hours from other provinces. Quality and service are guaranteed, low risk Feature description:

1. High-precision feeding: Jinzhide three-in-one feeder uses Mitsubishi PLC with Japanese imported servo motors and supporting drivers to achieve stable and high-precision feeding, with an accuracy of up to 0.01mm.

2. Save floor space and space: The three-in-one leveling feeder has the functions of discharging, leveling and feeding together. There is no need to equip the leveling machine and material rack. The main feature is space saving and reducing waiting area. Higher accuracy of feeding and leveling.

3. Convenient and fast loading and unloading: equipped with a loading trolley: the material is smoothly moved to the expansion and contraction structure of the uncoiler's main shaft, which is used to hold the material when uncoiling, so that the material belt can smoothly enter the leveling machine. (Optional)

Why choose us?

1st,We have a high level of technical research and development team;

2nd,We can provide the design and planning of the whole plant to realize the turnkey project;

3rd, our philosophy: quality is the social responsibility;

4th,our products have been recognized by the market, in the major automotive OEM, home appliance industry, hardware industry has been applied;

5th,We have a highly effective after-sales service team and get customer approval