Latest Multi-Power Customized Aluminum Powder Painting System Coating Machine with ISO9001

Zouping Hongyuan Eco-Friendly Mechanical Technology Co., Ltd.- Type:Coating Production Line

- Coating:Powder Coating

- Substrate:Steel

- Certification:CE, ISO

- Condition:New

- Transport Package:Plywood Box

Base Info

- Model NO.:HY-PLD

- Specification:40gp container

- Trademark:Hongyuan

- Origin:China

- Production Capacity:100sets Per Month

Description

Basic Info.

Model NO. HY-PLD Specification 40gp container Trademark Hongyuan Origin China Production Capacity 100sets Per MonthProduct Description

detailed specification of the Automatic Industrial Powder Coating Line for anything You produceIntroductions:

Choose the most suitable powder coating line according to your actual condition.

| A type: loading→spray pretreatment→drying oven→powder coating application automatically&manual repair→bridge type curing oven(tunnel with air curtain for option)→cooling naturally→off-loading |

| B type: loading→spray pretreatment→drying oven→powder coating application automatically&manual repair→curing oven with air curtain(bridge type for option)→cooling naturally→off-loading |

| C type: loading→spray pretreatment→drying oven→powder coating application automatically&manual repair with fast color change system curing oven with air curtain(bridge type for option)→cooling naturally→off-loading |

| D type: loading→spray pretreatment→drying oven→powder coating application manually→bridge type curing oven(tunnel with air curtain for option)→cooling naturally→off-loading |

| E type: loading→spray pretreatment→drying oven→powder coating application manually→curing oven with air curtain(bridge type for option)→cooling naturally→off-loading |

| F type: loading→spray pretreatment→drying oven→powder coating application automatically→curing oven with air curtain(bridge type for option)→cooling naturally→off-loading |

| G type: direct transverse system(the booth and the oven could be parallel or could be on a same line horizontally) |

| H type: power&free automatic powder coating convey line with shorter oven to improve the output. |

The followings are 4 common powder coating line, you can also contact me to help you to design the most suitable plan.

Mode 1: Manual powder coating:

Pretreatment, manual spraying, manual transfer to high temperature curing oven,then powder coating finish.

Advantages:

Low cost; Easy to operate; less occupied area.

Disadvantages: High demand for labor and Production capacity is slightly lower

Suitable for large and small batch production

Mode 2: Full automatic powder coating line:

Loading-spraying pretreatment (not including pickling)-drying in low temperature drying tunnel-automatic spraying-manual repair painting- high temperature oven curing-cooling the workpiece-unloading-powder coating finish.

Advantages: When spraying large quantities of the same workpiece, it will reduce the labor costs and energy consumption.

Disadvantages: Not suitable for small batch production. Requires high technical operation, complex maintenance and high maintenance costs, large area occupied.

Applicable to long-term batch spraying of fixed workpiece.

Mode 3: semi-automatic powder coating line:

Pretreatment (not in the coating line)-loading-manual spraying- high temperature oven curing-cooling-unloading -coating finish.

Introduction: The workpiece walking automatically with the spray chain, when passing through the coating booth with two spraying stations, 2 workers each holding a spray gun complete the spraying work; the workpieces after coating come out from coating booth, entering the constant temperature curing oven, then complete curing work.

Advantages: Much less investment and maintenance cost and difficulty than full automatic powder coating line. Almost the same daily output capacity with full automatic line.

Disadvantages: does not apply to irregular workpieces with small batch spraying, small batch will still cause high energy consumption and spraying cost.

Mode 4: the small circulation spraying chain and curing oven with 2 sides openning:

Building a small cycles spraying chain with 2 working station manual coating booth, workpiece hanging on the chain running automatically, passing through the coating booth in a constant speed, 2 workers each holding a manual spray gun spraying on the workpieces; then manually transferred the coated workpieces to curing oven; This spraying method, the spray ability accessible to" semi-automatic powder coating line ", but lower investment and smaller occupied area.

Advantages: high spraying efficiency, spraying quality is easier to control than mode 1; Daily output get close to mode 3, semi-automatic coating line if workers are matched well.

Disadvantages: does not apply to irregular workpieces with small batch spraying, small batch will still cause high energy consumption and spraying cost.

Certificate of our product and company

Certificate of our product and company

Our Team is serving you at any time

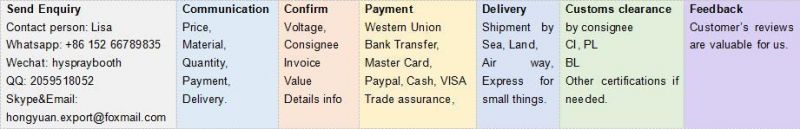

Contact person: Lisa, Mob.& : +86 152566789835