Small Casting Sand Screen Machine

Qingdao Ding Li Machinery Co., Ltd.- After-sales Service:After-Sales Service

- Warranty:One Year Warranty,

- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Automatic

Base Info

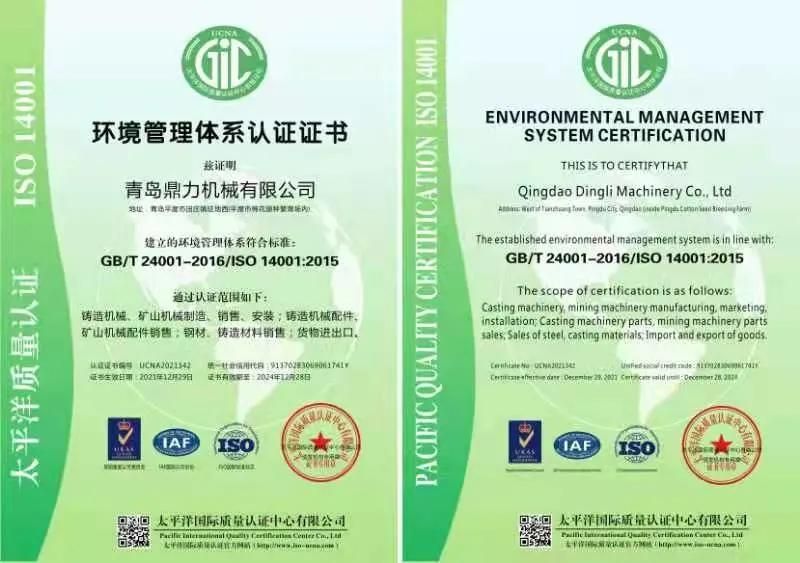

- Certification:CE, RoHS, GS, ISO9001

- Type:Sand Casting

- Transport Package:Custom

- Trademark:DL

- Origin:Qingdao, China

- HS Code:8474802000

- Production Capacity:600

Description

Basic Info.

Certification CE, RoHS, GS, ISO9001 Type Sand Casting Transport Package Custom Trademark DL Origin Qingdao, China HS Code 8474802000 Production Capacity 600Product Description

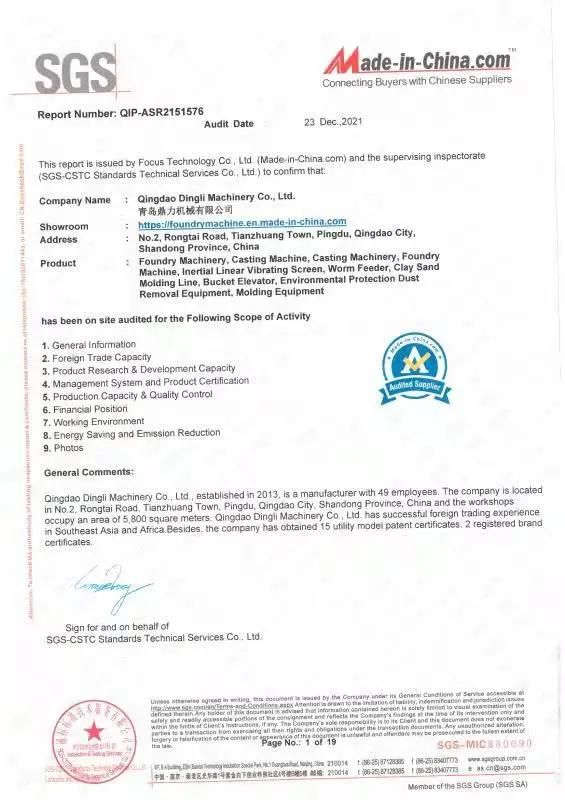

Qingdao Dingli Machinery Co., Ltd. is located in the beautiful seaside-Qingdao Pingda. the company set research,manufacturing,installationandcommissioning,after-sales service in one. It mainly produces resin sandproductionline,clay sandproductionline,coated sandproductionUne equipment, various sand treatment single machine equipment,etc. The company has advance casting machinerymanufacturinganddevelopmenttechnology,theproductionof products can full meet theinternationaland domestic market demand.The company has excellent design and R&D team, skilledconstructionteam, domestic leadwi casting equipment design concept,perfect after-sales service system, is willing to cooperate with the majority of foundryenterprisesto create a better tomorrow.

In line with the"down-to-earth, integrity-based, focus on service,continuousinnovation"businessphilosophy,throughcontinuousefforts. We use our own efforts and focus on thedevelopmentof a series of perfectprocessingequipment to meet the different needs of users.

Application: suitable for screening powder and granular materials in metallurgy, mining, chemical industry, building materials and casting workshops. At the same time of screening, ventilation and dust removal followed by cooling.

Features:

Smooth operation, reliable operation, fine screening.

Hexagonal big end feeding, the screen area is equivalent to increasing 30-40% near the theoretical speed of the material from the screen cylinder near the high point, to achieve crushing and fine screening;

Cold drawn stainless steel high strength coarse wire braided net, long service life; It can effectively screen and remove the hard particles larger than 4-5mm in the old sand, so as to make the sand quality uniform and improve the casting yield.

The screen mesh is fixed in the way of pulling and pressing, the net surface is tight, it is not easy to break, and the rebound crushing effect is good, and easy to replace.

Can be strong ventilation, control the mud content, and achieve a certain cooling effect. At the same time to reduce wet, hot, sticky material to sieve dew and adhesion.

Parameters Model | (t) Productivity(t/h) | (kw) Driving power(kw) | (mm) Hexagon at inlet end of screen cylinder Right angle(mm) | (mm) Mesh size(mm) | (M) Recommendedair volume (m²/h) |

| S4310 | 20-40 | 4 | 1100 | 6×16 | 6000 |

| S4313 | 40-60 | 5.5 | 1300 | 6×16 | 7000 |

| S4315 | 70-90 | 7.5 | 1500 | 6×16 | 8000 |

| S4318 | 90-110 | 11 | 1800 | 6×16 | 10000 |

| S4321 | 110-130 | 18.5 | 2100 | 6×16 | 13000 |