High Speed CNC Metal Plasma Cutter Machine for Ss CS

Jinan Lansen Laser Equipment Co., Ltd.- After-sales Service:Free Spare Parts

- Warranty:2 Years

- Customized:Customized

- Layout:Vertical

- Cutting Material:Carbon Steel, Iron, Stainless Steel

- Automatic Grade:Automatic

Base Info

- Model NO.:LSP1530

- Power Source:Electric

- Cutting Mode:Plasma Cutting

- Plasma Current:100A

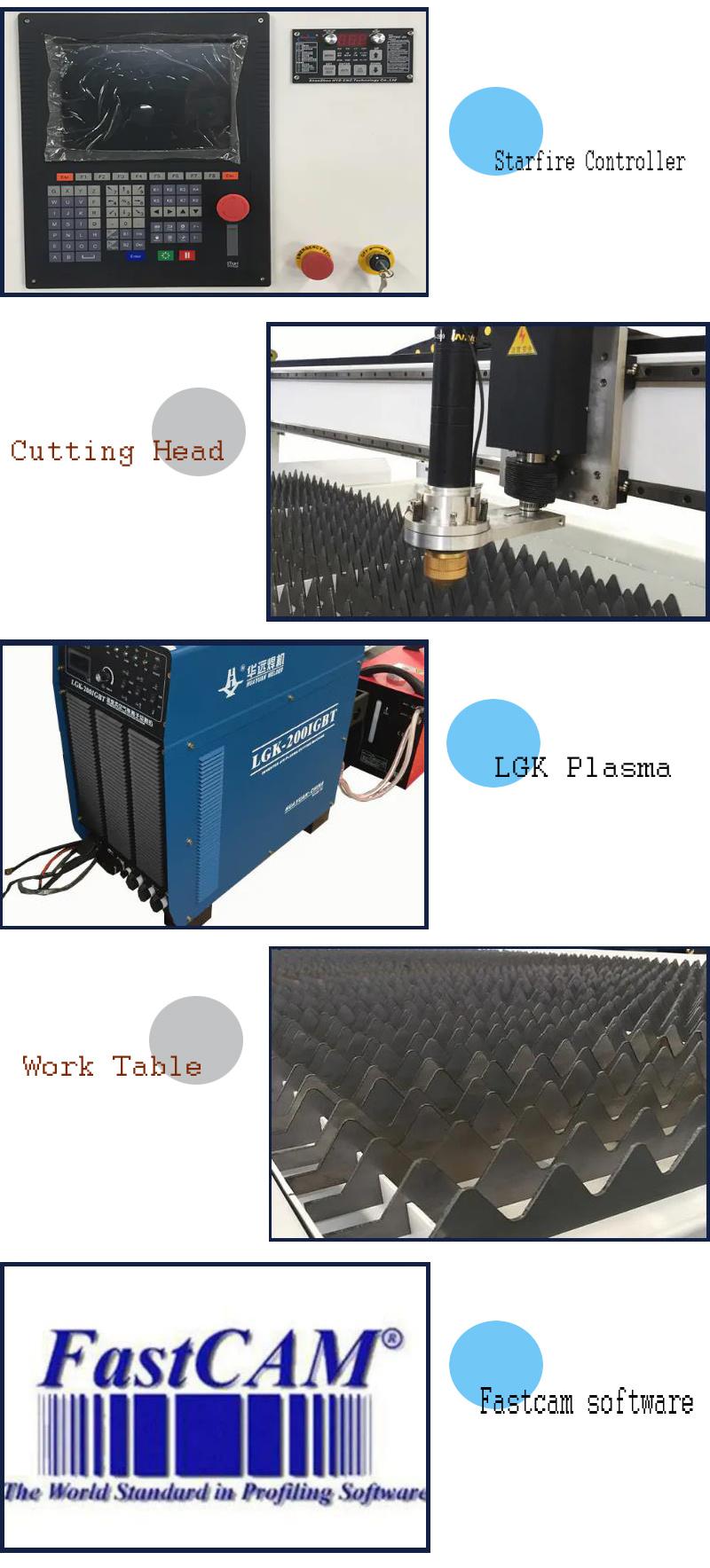

- Control System:Starfire

- Transmit Way:Gear Wheel

- Guide Rail:Linear Guide Rail

- Transport Package:Plywood Box

- Specification:Work size 1500*3000

- Trademark:Lansen

- Origin:China

- HS Code:8465990000

- Production Capacity:500 Sets,Year

Description

Model

LP-M1530P

Working area(mm)

1500x3000mm

Power supply

Huayuan(China), Thermadyne or Hypertherm (Import from USA)

Plasma currency

40A/60A/100A/160A/200A

Control system

DSP or Beijing Start

Cutting thickness

Depend on plasma currency

Cutting speed

100-8,000mm/min

Moving speed

0-50,000mm/min

Precision

±0.1mm

Repeating precision

±0.8mm

Power

8.5-10.5kw

Voltage

380v/50Hz

Working atmospheric pressure

0.65-0.7Mpa

Communication interface

USB port

Arc pressure adjuster

Hipost AHC-2C

Software support

FASTCAM, AutoCAD, Type 3 etc. Software

Instruction format

G code

Machine parts:

Machine body: Thick steel welded bed (rugged and reliable, no distortion, carrying heavy, strong stability)

Gantry:Use 10mm thickness steel (very stronger, more durable and stability)

Plasma Power: international famous brands, low failure rate

Rail: Taiwan Hiwin side rails (bearing, guide, control precision effects)

Rack: straight teeth (high speed, high precision)

Control System: Beijing StarFire (Sino-US joint venture, stable performance, simple operation)

Countertops: 4mm serrated rack (load capacity, accuracy is more accurate)

Bed structure: GB artificial aging overall secondary vibration welding bed

Electrical accessories: High quality electronic components, high flexible shielded cable (resistant to water, bending, anti-oil).

Packages:

Warranty:

1. Installation

After the machine reach the buyer's site,the engineers from the seller are responsible for machine installation and commissioning by using the special tools under the help of the buyer. And then start training the workers. Tickets, hotel and food charge need to afford by buyers

2. Training

The common protection knowledge of laser safety

The basic principle of laser module and the structure of laser cutting machine

The operation skills of fiber laser cutting machine

Equipment operation and the application notice

Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.

Training time is about 5 to 10 days.

3. After sales service

·2 year warranty for the whole machine

·2 years warranty for the fiber laser source

·Life-long maintenance

·In the warranty period,if it break down or some parts damaged(Except the human factors and the factors of force majeure),the seller should be responsible for repair for free,the parts need to be replaced will be provided from seller for free(Except the Consumable parts)

·After the warranty period expired,the buyer only need to pay the actual maintenance cost

·Lansen will pay a return visit all customers for several times one year,and will provide technical support service anytime, and also provide spare parts anytime the buyer want

·After sales service response time: quick response within 8 working hours,after receive the repair call, our after sales engineer will reply as soon as possible

Company:

FAQ:

Q: How can I choose suitable machine?

A: Please communicate with us via inquiry or email, we can guide you. Please kindly tell us:

1) .What work table size you will need?

2).What work you will do?

Q: What's your payment terms? Delivery time and MOQ?

A: We accpet T/T(bank transfer), L/C, Paypal, Western union etc. Usually we need 30% as deposit, balance paid before shipment.

Delivery Time: 3-5 days after payment

MOQ: 1set

Q: If I bought a machine, how could you make it safe while shipping.

A: We have a professtional package suitable for oversea transpotation. Machine will be fixed well in the case.

Q: What's your quality control system?

A: All machines will be tested after finished. We have QC department response for this job. And we already got CE approved.

Q: If I don't know how to use the machine, can you teach me?

A: 1) There is a DVD disc including machine user manual and software user manual c/w machine.

2) Online (skype & phone)

3) Remote desktop software (Teamviewer)

4) Demo Video