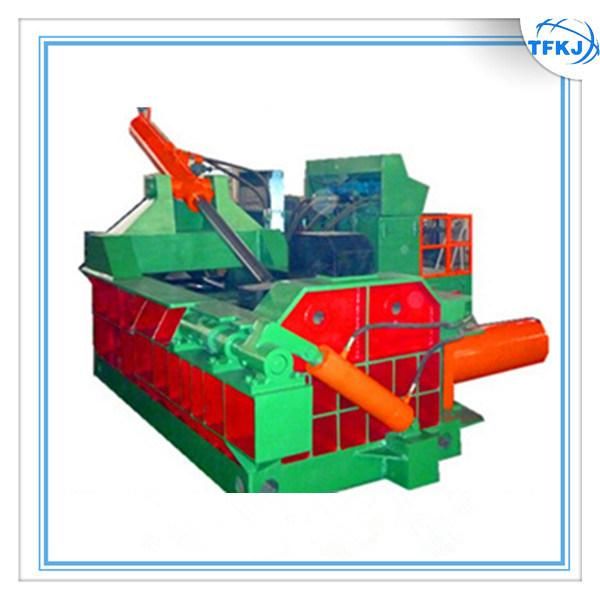

Y81/F-2500b Hydraulic Scrap Aluminum Baling Machinery

Jiangyin Tianfu Technology Co., Ltd.- Application:Metal Scrap, Steel,Iron,Copper,Aluminum etc.

- Compression Room:1800*1400*800mm

- Bale Size:450*450mm

- Capacity:4-5t,H

- Cooling:Water or Air Cooler

- Operation:Automatic or Hand Valve

Base Info

- Model NO.:Y81,F-2500B

- Warranty:12months

- Transport Package:Host Nude Packing, Parts Can Be in Wooden Cases

- Specification:CE,ISO9001: 2000

- Trademark:Tianfu

- Origin:Jiangsu China

- HS Code:8462919000

- Production Capacity:1000 PCS,Year

Description

Basic Info.

Model NO. Y81/F-2500B Warranty 12months Transport Package Host Nude Packing, Parts Can Be in Wooden Cases Specification CE/ISO9001: 2000 Trademark Tianfu Origin Jiangsu China HS Code 8462919000 Production Capacity 1000 PCS/YearProduct Description

1.Application:Y81 series of hydraulic metal baler is applicable in steel plants, recycling companies, ferrous & non-ferrous smelting industry to press metal scraps(steel, copper, aluminum, stainless steel, discarded automobiles)into acceptable fumace charges(shapes: Cuboid; Cylinder or octagon), so as to reduce cost of transportation, to increase speed of fumace charging.

2.Features:

1)Hydraulic drive for all machine types, manual valve control or PLC control.

2)Bale-discharging: "turn-out", "push-out", "forward-out" or manual discharging.

3)No footing bolts needed in installation; Diesel engine can be equipped for power.

4)Baling force 10 grades from 63 to 400 tons; Productivity from 4 to 40 tons per shift(8 hours).

3. How to choose your baler correctly:

1) If your scrap material is scrap metals, non-ferrous metals, color metals we recommend Y81/F series metal baler to you, which has high pressing force with bales tilting out design.

2) If your scrap material is lightweight metals, such as scrap aluminium, scrap copper, tin cans,Buckets, we recommend our Y81/Q series metal baler to you, the bales will be pushed from Baler forward.

3) If your scrap material is heavy metals, then we recommend our Y81/T series metal balers to

You, the bales will be pushed out from the side of the metal baler.

4. Advantages:

1). Our baler machine under 250 ton is integral structure. Hydraulic station connects with the host machine together. So it doesn't need to install. One machine puts in one 20" container. And it saves ship cost.

2). Our company use high-strength wear-resistant plate import from America, the plates are available 15 years, do not need to change, the price is as 5 times as the common, common plate life is three years.

3). We use good quality seals, so no oil leak.

4). Inner blades, water cooler, protective net, hosepipe, flange, big pressure head, relief valve, oil temperature gauge.

5. Service:

1) Lifelong maintenance and considerate technical support!

2) Any problem before or after delivery, you could find and talk with us anytime anywhere.

3) Technicians can be sent to abroad, door to door service.

4) Video / CD of test running and installation, User's Manual.

5) Complete parts & tools in box sent with machine.

Model | Nominal Force (KN) | Material box size(L*W*H) (mm) | Bale Size (mm) | Bale Density (kg/m 3 ) | Capacity (kg/h) | Cycle Time (s) | Power (kw) |

| Y81-630 | 630 | 1000*600*500 | (180-250)*200*200 | > 1800 | 500-1000 | 90 | 7.5 |

| Y81-1000 | 1000 | 1000*600*500 | (200-300)*230*230 | > 1800 | 1000-1200 | 120 | 11 |

| Y81/T-1000 | 1000 | 1000*600*500 | (200-300)*230*230 | > 1800 | 1000-1200 | 120 | 15 |

| Y81-1250 | 1250 | 1200*700*600 | (150-360)*300*300 | > 1800 | 1000-1500 | 120 | 15 |

| Y81/T-1250 | 1250 | 1200*700*600 | (250-400)*300*300 | > 1800 | 1500-2000 | 80 | 18.5 |

| Y81Q-1350 | 1350 | 1400*600*600 | (240-450)*600*240 | > 1800 | 1800-2500 | 80 | 22 |

| Y81-1600 | 1600 | 1600*1000*700 | (400-600)*400*400 | > 1800 | 2000-3000 | 150 | 22 |

| Y81/T-1600A | 1600 | 1600*1000*800 | (400-600)*400*400 | > 1800 | 2000-3000 | 150 | 22 |

| Y81/T-1600B | 1600 | 1600*1200*800 | (400-600)*400*400 | > 1800 | 2000-3000 | 160 | 30 |

| Y81-2000 | 2000 | 1600*1200*800 | (400-600)*400*400 | > 1800 | 2500-4000 | 160 | 30 |

| Y81/T-2000A | 2000 | 1600*1200*800 | (400-650)*400*400 | > 1800 | 2200-4000 | 160 | 30 |

| Y81/T-2000B | 2000 | 1800*1400*900 | (400-700)*450*450 | > 1800 | 2500-4500 | 160 | 37 |

| Y81-2500 | 2500 | 2000*1400*900 | (400-700)*500*500 | > 1800 | 3500-5000 | 160 | 37 |

| Y81/T-2500A | 2500 | 2000*1400*900 | (400-700)*500*500 | > 1800 | 3500-5000 | 160 | 44 |

| Y81/T-2500B | 2500 | 2000*1750*1000 | (450-800)*500*500 | > 1800 | 3500-5000 | 160 | 60 |

| Y81-3150 | 3150 | 2000*1400*1000 | (400-700)*500*500 | > 1800 | 3500-5000 | 160 | 60 |

| Y81/T-3150 | 3150 | 2000*1600*1200 | (450-700)*550*550 | > 1800 | 4000-5000 | 160 | 66 |

| Y81/T-4000A | 4000 | 2000*1600*1200 | (450-800)*550*550 | > 1800 | 5000-6000 | 160 | 74 |

| Y81/T-4000B | 4000 | 2600*2000*1200 | (500-1000)*600*600 | > 1800 | 5000-7000 | 180 | 90 |

| Y81/T-4000C | 4000 | 5000*2000*1200 | (500-1200)*700*700 | > 1500 | 8000-10000 | 200 | 135 |

| Y81/T-6000 | 6000 | 3200*2000*1200 | (500-1200)*700*700 | > 1800 | 7000-9000 | 180 |