Environmental Friendly Electric Heavy Steel Shell Furnace with Dust Ring for Metal Casting

Foshan Hengyang Furnace Manufacturing Co., Ltd.- Control Type:PLC

- Customized:Customized

- Condition:New

- Automatic Grade:Semi-Automatic

- Certification:CE, ISO9001

- Type:Sand Casting

Base Info

- Model NO.:GW-5T

- Melting Material:All Metal

- Furnace Capacity:5-6 Tons

- Melting Time:50-60 Minutes

- Max Temperature:1800 Degrees

- Cooling System:Water Cooling System

- Water Comsumption:100t,H

- Pouring:Hydraulic Pouring

- Tilting Angle:Vertically at 95 Degrees

- Power Consumption:About 550kwh,T

- Rated Power:3000kw

- Rated Voltage:950V

- Input Current:912*2A

- Input Power Frequency:50Hz,60Hz

- After Sales Service:Engineers Oversea Service Available

- Warranty:1 Year

- Transport Package:Customized

- Specification:3330*3000*2930mm

- Trademark:HENGYANG

- Origin:China

- HS Code:8514200090

- Production Capacity:600sets,Years

Description

b. aluminum shell furnaces

c. small capacity melting furnaces

d. heating furnaces

e. cooling tower

f. transformer

g. linning material

h. crucibles

i. ladles

J. other spare parts

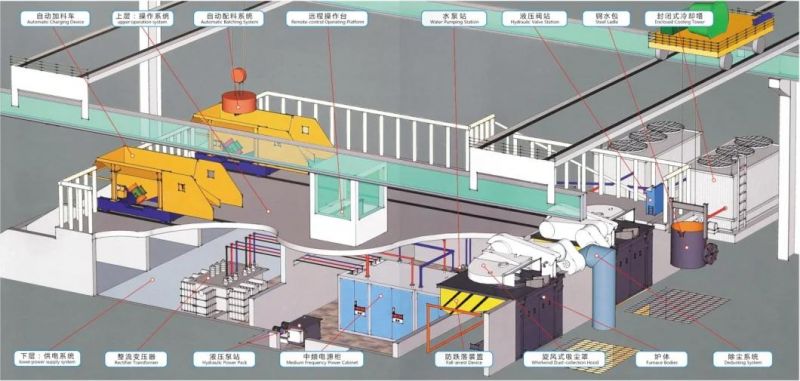

b. automatic feeding car

c. automatic batching machine

d. dust removal system

e. continuous casting machine

f. rolling mill

Common Questions & Solution

1 ) How is the temperature of the furnace measured / calculated?

There are two ways to measure it.

One is artificial way. You can buy a temperature probe to measure the temperature by yourself.

Another is automactical way. Automatic Thermostatic Function is available.

You can set up temperature needed in advanced by controlling the temperature button.

2 ) Is there a measurement to determine when the furnace liner needs to be replaced?

Leakage detected system is available. which has the following two advantages:

a. In case the molten iron leaked from furnace and touch the induction coil, workers will be protect from electric shock even when they are holding a metal rod to touch the molten metal for slag removal or temperature measurement. Besides, there is no induction electricity in the melting metal during regular working.

b. Earthing and leakage condition can still be detected, though the power supply has stopped working.

3 ) Compared with gas /oil /coal fired furnace, what are your advantages?

a. High productivity. As heating fast, the material utilization of induction furnace up to 95-99%. Its oxidation loss is less than0.5%, while gas furnace loss 2%, and coal-fired furnace loss 3%. It can reduce 1.5% slag.

b. Reduce the cost of production. As uniform heating, induction furnace extends the using life of casting mould(10%-15%) .

c. Energy saving. induction furnace use electricity as fuel, it can save 31.5% ~ 54.3% power than oil-fired furnace, 5% to 40% than gas furnaces.

d. Environmental-friendly. Workers have better working environment, and it improve company's image. Being no pollution, low energy , company can reach the targets environmental protection departments and establish a future with the forging industry trends.