Stainless Steel Pipe Polishing Machine Mesh Screen Pipe Pipe Belt Machine

Foshan Gaoming Yongshunfa Building Materials Co., Ltd.- Certification:ISO, CE

- Condition:New

- Voltage:220,380,415,420,440V

- Application:to Polish Pipes Surface

- Warranty:1 Year

- Capacity:3-18m,Min

Base Info

- Pipe Diameter:38-219mm

- Pipe Thickness:Automatic New Type

- Wheel Head Main Power:4,5.5,7.5kw*10,4kw*8

- Product Name:Round Pipe Polishing Machine

- Useful Time:20 Years

- Color:Blue,Green,Grey,White or at Your Request.

- Pre-Sales Service:Workshop and Production Output Design

- After-Sales Service:Field Installation,Commissioning and Training.

- Pipe Shape:Round

- Wheel Head Shaft Diameter:36mm

- Market:The Middle East, Southeast Asia,etc

- Polishing Effect:Mirror Polish

- Pipe Polishing Material:Flap Wheel,Sisal Wheel,Polishing Wax

- Transport Package:by Container

- Specification:7500*1500

- Trademark:YONGJIAN MACHINERY

- Origin:Guangdong, China(Mainland)

- HS Code:84639000

- Production Capacity:30 Sets,Month

Description

APPLICATION

Round Pipe Polishing Machine

Polishing machine mainly used for polishing and drawing the surface of stainless steel pipe.Polishing technology processes:feeding,polishing(flap wheel,sisal round,cloth round,wind cloth round)plus polishing wax,and discharging.The polishing machine is widely used in the decoration industry.

Parameters

we can also design and produce according to customer requirements.

| Model | Pipe Diameter(mm) | Wall thickness(mm) | Production Capacity(m/min) | Tube tolerance(±mm) | Wheel head(kw) | Wheel Head Shaft Diameter | Material |

| Group 32 of Tube Polisher | F10xF10-F100xF100 | Automatic New Type | 3-30 | ±0.05 | 4KWx32 | ∮36 | ss,cs,etc |

| Group 28 of Tube Polisher | F10xF10-F80xF80 | Automatic New Type | 3-30 | ±0.05 | 4KWx28 | ∮36 | ss,cs,etc |

| 8 Wheel Head Small Tube Polisher | ∮8-50.8 | 0.25-1.8 | 6-30 | ±0.05 | 4KWx8 | ∮36 | ss,cs,etc |

| 10 Wheel Head In Tube Polisher | ∮19-76 | 0.4-2.5 | 5-24 | ±0.05 | 4KWx10 | ∮36 | ss,cs,etc |

| 10 Wheel Head Big Tube Polisher | ∮50.8-114 | 0.7-3.0 | 3-18 | ±0.05 | 5.5KWx10 | ∮36 | ss,cs,etc |

| 10 Wheel Head Big Tube-1 Polisher | ∮114-219 | 1.0-4.5 | 3-18 | ±0.05 | 7.5KWx10 | ∮36 | ss,cs,etc |

| Auto-Press Round Polishing Machine | ∮19-114 | Automatic New Type | 3-18 | ±0.05 | 7.5KWx10 | ∮36 | ss,cs,etc |

| Auto-Press Round Polishing Machine-Large | ∮38-219 | Automatic New Type | 3-18 | ±0.05 | 7.5KWx10 | ∮36 | ss,cs,etc |

Details

Motors

Rubbers

Loading Shelf

1. Using automatic operation mode. After artificial laying of pipe. The equipment is self-urrioading and delivers the pipe to the polishing host.

2. Using roller conveying mode, can effectively reduce the probability of pipe scratches. After the pipe is conveyed, the pipe is removed by pneumatic device/material turning devic.Then collecting and packing by manually.

Efficiency

Adopt to 8-10 group high frequency motor as driving, its production speed is up to 30m/min.

Anti-corrosion

1. The grinding group machine table which easy to erode have installate the stainless steel plate.

2. Corrosion of parts to do protective surface treatment to extend the service life of the machine.

3. Useful time is more than 20 years by the practice.

Packing & Shipping

1. We use steel wire and wooden frame to fix the pipe mill

2. In addition, used shockproof film to protect the main motors.

3. We use the container to deliver goods to our customer. Generally speaking, we start at Foshan port, but we also can start at other port according to customers need.

Intergrated services:

1. Provide customers with a reasonable investment plan, filter the appropriate models recommended to customers.

2. Free equipment drawings, customer plant equipment planning drawings.

3. Provide the base map required for installation free of charge.

4. Provide equipment installation and commissioning until the buyer operates normally.

5. Provide professional technical training, as soon as possible to allow the buyer's operator to master the operation and use of the equipment.

6. Provide and coordinate auxiliary equipment, accessories, and consumables.

7. The warranty period is one year, except man-damage.If you have any question in operation in operating the machines, you can call us or send emails, we will solve the problem for you asap.

Other popular products

Foshan Yuanyongjian Pipe Making Mold&Machinery Co., Ltd. is a professional manufacturer of stainless steel welded pipe molds, welded pipe machinery, high frequency pipe welding machine and stainless steel pipe machine, polishing machine, composite pipe machine, online bright solution annealing equipment and other ancillary equipment. Manufacturer of stainless steel production lines. Advanced production equipment, strong technical force, modern management system The company has the ability to independently design and develop various new products, and the equipment is sold all over the country.

Industrial Pipe Making Machine

Decorative Pipe Making Machine

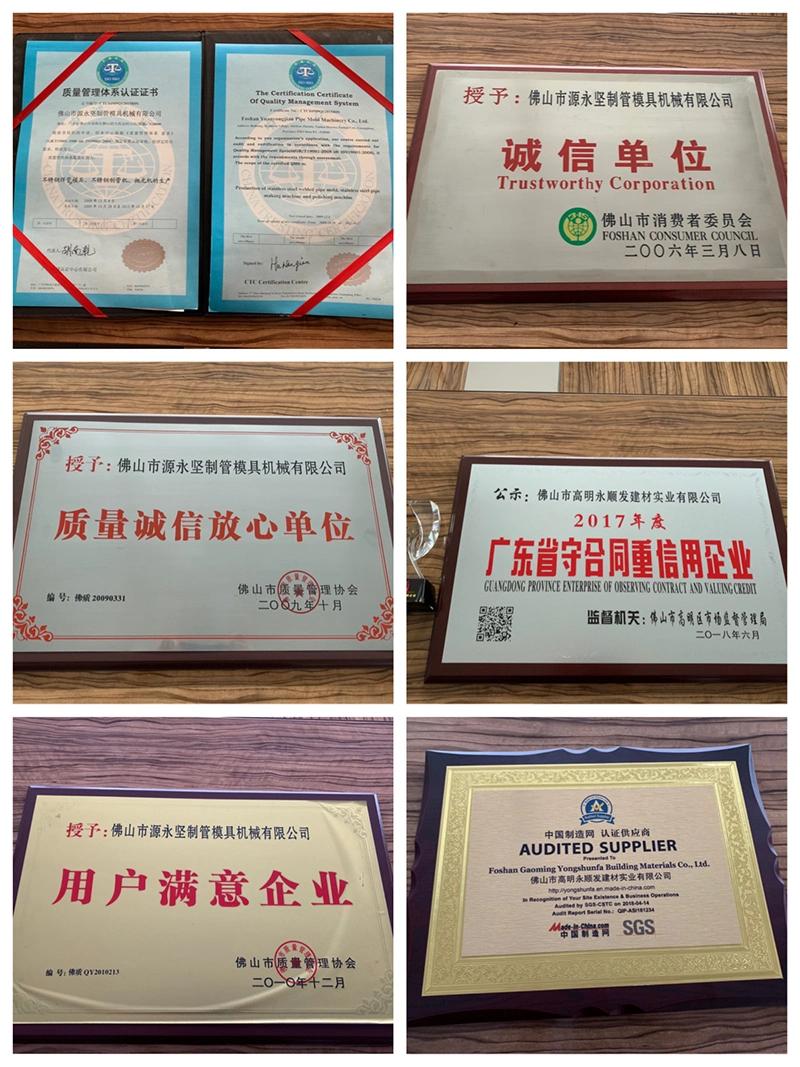

Certification

Participate in the exhibition

FAQ

Q: Do you had building an independent factory?

A: We have our own factory.Our company is based on the original factory and birth out the professional sales company.

Q: What kind of services can you give us?

A:1. Pre-sale can be targetd to give some constructive comments.

2. Develop a specific plan for your needs.

3.After-sales reference to specific products, different with different service. Refer to the specific product description.

Q: What does the quality of pipe polishing machine?

A: Our company always in line with the high quality standard of the current market, we try our best to meet the requirements for the oversea and domestic customers.

Q: Is there any other equipment buyer need to purchase?

A: Buyer need to purchase some spare parts such as bearing, magnet bars for welding, saw blades for cutting, which is necessary in the later production. Buyer also need to purchase eletric wires for connection, water pump for recycling water and material for making machine foundation, etc. We can also provide buyers with everything if buyer want one-stop service.

Q: What is the difference between you and other Chinese suppliers? What is the advantage?

A:1. We are sale enterprise, but we have our own factory. Products quality can be promise.

2. We can feedback the process at any time, making you to stay at home will be able to clear in the heart.

3.We have 20 years technology experience.

4. If conditions permitting, we can provide the appropiate services at any time.

Q: If we provide parameter requirement, can be customized?

A: We provide the corresponding customized services, as long as you provide the appropriate drawings and product requirements can be fine.

Q: How long about your delivery time? Can be delivered on time?

A: Our leading time varies according to order quantity, at usually is 30-45 days (within 10 sets decorative pipe making machine) ; 45-60 days (within 10 sets industrial pipe making machine).