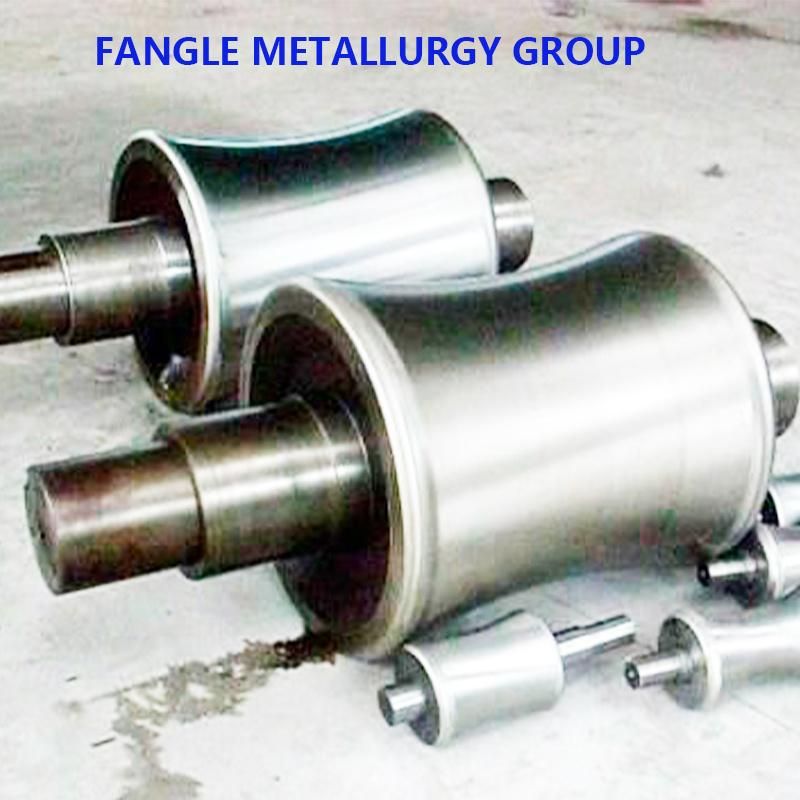

Straightening Roller for Hot Rolling Seamless Steel Tubes Production Line

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Straightening Mill

- Transport Package:Woodern Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- Production Capacity:20000 Tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Straightening Mill Transport Package Woodern Case Specification Export package Trademark FANGLE Origin China Production Capacity 20000 Tons/YearProduct Description

The straightening roller is the key part of the straightening mill.Its material is mainly 9Cr2Mo.The straightening process is to make the tube straightening and reduce the cylindricity of the tube, and the surface of the pipe is also polished and strengthened.The basic structural parameters of the roller straightener are the diameter of the waist of the straightening roller and the length of the body of the straightening roller.The diameter of the waist of the straightening roller depends on the pressure of the pipe on the straightening roller and is determined according to the load characteristics.In the range of the diameter of the straight steel pipe, the tube with the smallest diameter has the worst rigidity and the largest rotation speed, so the design should adopt the parameters of the tube with the smallest diameter to determine the roll shape.