- Model NO.:TOB-TBJY300-1J

- Material:SUS304 Stainless Steel

- Heating Power of Single Section Oven:6kw

- Fan Control:Contactor Control

- Transport Package:Standard Export Packing

- Trademark:TOB

- Origin:Fujian, China

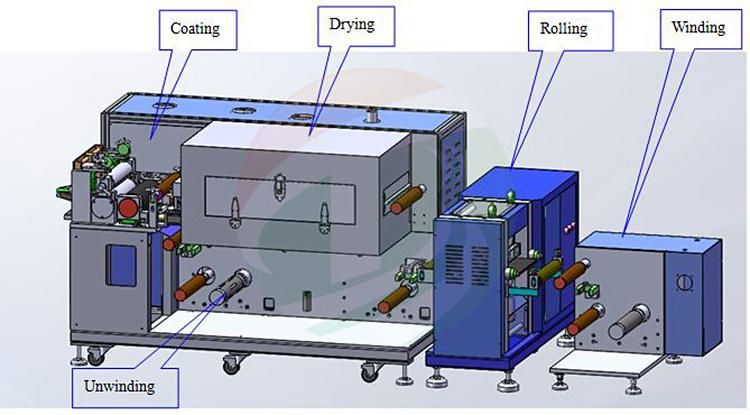

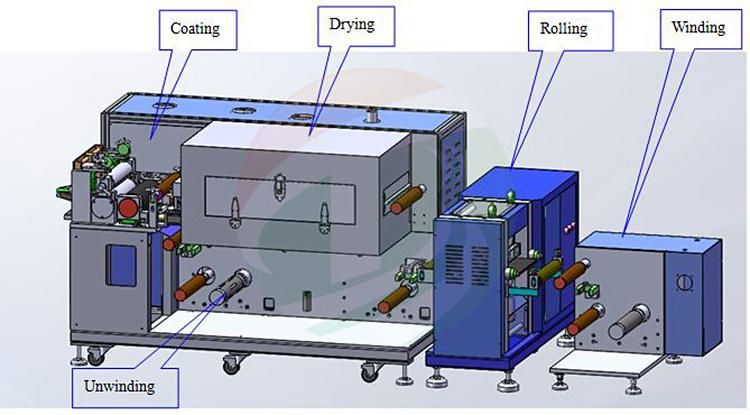

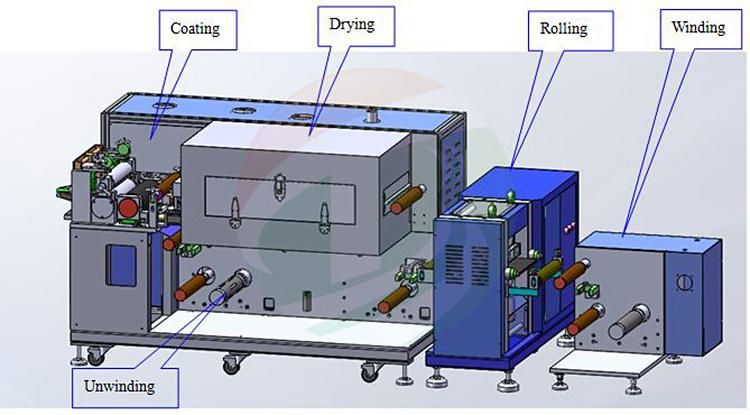

Feeding Unwinding material method| The material roll is fixed by a 3-inch inflatable shaft; | | | Unwinding single air expansion shaft | |

| 6. | Maximum unwinding diameter | Ф250mm | |

| 7. | Maximum load of inflatable shaft | 80Kg | |

| 8. | Number of unwinding and inflation shafts | 1Pcs | |

| 9 | Main drive motor | Servo motor | |

| 10 | Roller surface treatment | Surface oxidation of metal aluminum roll | |

| 11 | Scraper structure | Double-sided comma scraper | |

| 12 | Coating roller (steel roller) | Hard chrome plating | |

| 13 | Back roller (rubber roller) | The surface is wrapped with imported EPDM | |

| 14 | Scraper intermittent height adjustment | Manual adjustment; | |

| 15 | Single head position | Installation and operation before drying tunnel | |

2. Coating drying tunnel| No | Item | Technical Parameters | Remark |

| 1. | Oven structure | Double-layer independent heating, arranged up and down | |

| 2. | Oven length | 1 meter / section | |

| 3. | Material | SUS304 stainless steel | |

| 4. | Temperature control | Divided into normal working temperature control, over-temperature monitoring and alarm protection control, and cut off the heating main power supply; each section is completely independent control | |

| 5. | Heating method | Analog signal control power heating, hot air circulation structure | |

| 6. | Heating power of single section oven | 6KW | |

| 7. | Temperature in drying tunnel | Design Max150 ºC, temperature difference in single section oven≤ ± 2.5 ºC | |

| 8. | Blowing method | Upper and lower air blowing, common heating body for upper and lower air chamber | |

| 9. | Wind nozzle structure | The nozzle slot is slotted by a special mold | |

| 10. | Fan control | Contactor control | |

| 11. | Heating control | solid state relay | |

| 12. | Fan material | SUS304 stainless steel | |

| 13. | Solvent recovery system | Optional | |

*Roller winding function:| 1 | Rolling purpose | Roller press the battery material coated on aluminum foil or copper foil | Remark |

| 2 | Maximum opening thickness of rolling mill | 2 mm | |

| 3 | Rolling width | Max 300 mm | |

*Roller winding parameters:| 1 | Rolling force | Max. 35T(Can be customized to increase) | Remark |

| 2 | Mechanical speed | Max.10m/min | |

| 3 | Roll diameter: | Ф200 mm;Material:9Cr3Mo | |

| 4 | Roller surface hardness | >HRC65 | |

| 5 | Roller surface width | 330 mm | |

| 6 | Pushdown mode | Hydraulic | |

| 7 | Rolling accuracy | ±2.5 um | |

| 8 | Maximum opening of rolling mill | 2 mm | |

| 9 | Reducer and gear box | Modular | |

| 10 | Rolling mill motor | AC frequency conversion motor | |

| 11 | Winding | With correction function and tension control function | |

*Control System:| No | Item | Technical Parameters | Remark |

| 1 | Main control system | Touch screen, PLC, servo system | |

| 2 | Operation mode | Manual, automatic, emergency stop; the whole machine can be operated before and after | |

| 4 | Alarm situation | When the device fails, the touch screen will display the corresponding correction screen | |

*Hardware accuracy| No | Item | Technical Parameters | Remarks |

| 1. | Scraper | Round jump≤ ± 1.5um, Ra0.4, straightness≤ ± 1.5um | |

| 2. | Coating roller (steel roller) | Round jump ≤ ± 1.5um, Ra0.4 straightness≤ ± 1.5um | |

| 3. | Glue roll | Round jump ≤10um,straightness≤10um | |

| 4. | Roll | Round jump≤ ± 2um, Ra0.4, straightness≤ ± 2um | |

| 5. | Deviation correction | ±0.2mm | |