3D Steel Tile Roll Forming Machine

Zhangjiagang City Saibo Science & Technology Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Electric

- Feature:High Efficiency

- Certification:ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:YX19-185-1100

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Color:Blue and Yellow

- Machine Name:3D Steel Tile Roll Forming Machine

- Coil Width:1220mm

- Thickness:0.4-0.6mm

- Main Power:5.5kw

- Transport Package:No Packing

- Specification:CE, SGS

- Trademark:SAIBO

- Origin:Suzhou, China

- HS Code:84552210

- Production Capacity:300sets,Year

Description

Specification of the material1

Suitable Material Colored Steel plate 2

Width of the raw material 1220mm 3 Thickness 0.4mm-0.6mm

2. Machine Detailed Parameters:

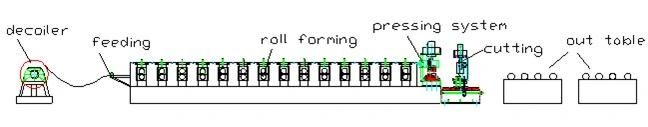

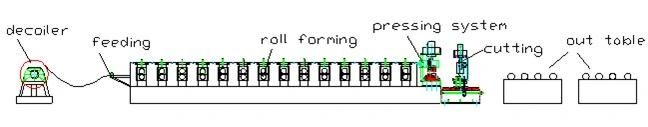

3. The Chart of Process Flow

Manual de-coiler→ Feeding→roll forming→pressing& post cutting →Out table

4. Specification of Components

5. Packing & Delivery

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 100$ per day shall be for purchaser's account if manufacturer's engineer has to be send to purchaser's factory to maintain the machine during the guarantee period.

6. Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment

eel Tile Roll Forming Machine

2. Machine Detailed Parameters:

| 1 | Machine structure | Guide pillar structure |

| 2 | Total power | Motor power-5.5kw Hydraulic power-5.5kw |

| 3 | Roller stations | About 18stations |

| 4 | Productivity | 2-4m/min(excluding pressing and cutting) |

| 5 | Drive system | By chain |

| 6 | Diameter of shaft | ¢70mm solid shaft |

| 7 | Voltage | 380V 50Hz 3phases (Customized) |

3. The Chart of Process Flow

Manual de-coiler→ Feeding→roll forming→pressing& post cutting →Out table

4. Specification of Components

| No | Technical Specification & Remark | |

| 1 | 5T Manual de-coiler |

|

| 2 | Main Roll Forming Machine |

|

| 3 | Machine structure: |

|

| 4 | Pressing & cutting system |

|

| 5 | Hydraulic System |

|

| 6 | Computer Control Cabinet |

|

| 7 | Out table |

|

| 8 | Spare Parts |

|

- Deliver time: take goods after receive deposit 70 days

- Packing: suitable of ocean transportation

- Warranty: 1 year warranty from date of shipment

- Guarantee:

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 100$ per day shall be for purchaser's account if manufacturer's engineer has to be send to purchaser's factory to maintain the machine during the guarantee period.

6. Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment

eel Tile Roll Forming Machine