Furnace to Heat The Components

Zouping Hongyuan Eco-Friendly Mechanical Technology Co., Ltd.- After-sales Service:Available

- Warranty:12months

- Type:Powder Coating Curing Oven for Metal Parts

- Coating:Powder Coating

- Substrate:Steel

- Certification:CE, ISO, SGS

Base Info

- Condition:New

- Outer Size:4800*2300*2400

- Panel:100mm Thickness Rockwool Insulated Panel

- Heating System:Gas

- Burner:Riello Gas Burner

- Circulation Fan:1set

- Ground Rail:1set

- Highest Temp:200degree

- Control Box:1 Set, English Panel, Other Language for Option

- User Manual:Available

- Drawing:Available

- Control Mode:Automatic

- Transport Package:Standard Package for Sea Shipment

- Specification:10cbm for LCL

- Trademark:N,A

- Origin:Shandong, China

- Production Capacity:100 Set Per Month

Description

Basic Info.

Condition New Outer Size 4800*2300*2400 Panel 100mm Thickness Rockwool Insulated Panel Heating System Gas Burner Riello Gas Burner Circulation Fan 1set Ground Rail 1set Highest Temp 200degree Control Box 1 Set, English Panel, Other Language for Option User Manual Available Drawing Available Control Mode Automatic Transport Package Standard Package for Sea Shipment Specification 10cbm for LCL Trademark N/A Origin Shandong, China Production Capacity 100 Set Per MonthProduct Description

The powder coating process involves three basic steps:

- Part preparation or the pre-treatment

- The powder application

- Curing

1. Part preparation processes and equipment

2. powder coating spray gun(manually or automatically)

3. powder coating spray booth(manually or automatically)

4. powder coating curing oven(gas, diesel, or electric heating energy for option)

5. powder coating production line(manually or automatically)

Quick details of the furnace to heat the components

Outer size(D*W*H): 4800*2300*2400mm

Inner Clear size(D*W*H): 4500*2000*2000mm

heating power: gas burner.

entry door: 1set, one for in and out.

Function of the furnace to heat the components

The powder coating curing oven is mainly for curing the object coated by powders, which is the most important and vital part during the powder coating process.

Parameters of the furnace to heat the components

| Model | HY-PO4800G1 |

| Outer size(mm) D*W*H | 4800*2300*2400 |

| Inner Clear size(mm) D*W*H | 4500*2000*2000 |

| Cabin system | 100mm/75mm thickness rockwool sandwich panel. |

| Entry/off door | One set of end-door, for in and out. |

| Power supply | GAS |

| Voltage | 110V/220V/380V/450V |

| Frequency | 50-60Hz |

| Warm-up time | 15 min. (180-220° C) |

| Temp Homogeneity | < ± 3°C if 185°C |

| Temperature stability | < ± 1°C |

| Temperature max. | 230° C |

| Air circulation | Hot air circulation |

| Band of burner | Italy Riello Gas burner |

| Warranty | 12 months |

| Transport | By sea |

| Optional | Size could be custom-made. |

| Transfer trolley | excluded |

| Related products | Powder coating gun, powder coating machine, powder coating spray booth, powder coating plant, powder coating spray line |

Related products of our furnace to heat the components

powder coating spray booth, powder coating spray machine, powder coating plant, powder coating spray production line, powder coating spray gun and so on.

Parts show of furnace to heat the components

Production area and equipment for furnace to heat the components

Package Show of furnace to heat the components

Certificate of our product and company

Our Team is serving you at any time

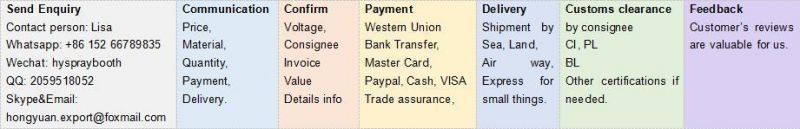

Send us inquiry for more info about furnace to heat the components

Without communication, there is no relationship;

without respect, there is no love;

without trust, there is no reason to continue!

Happy new year to you all! Wish the best to your family!