Ce Standard Automatic Welding Line Polishing Machine for Hot Sale

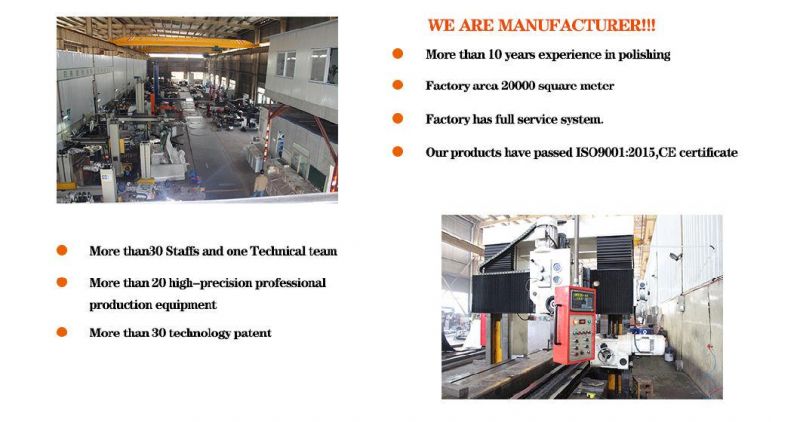

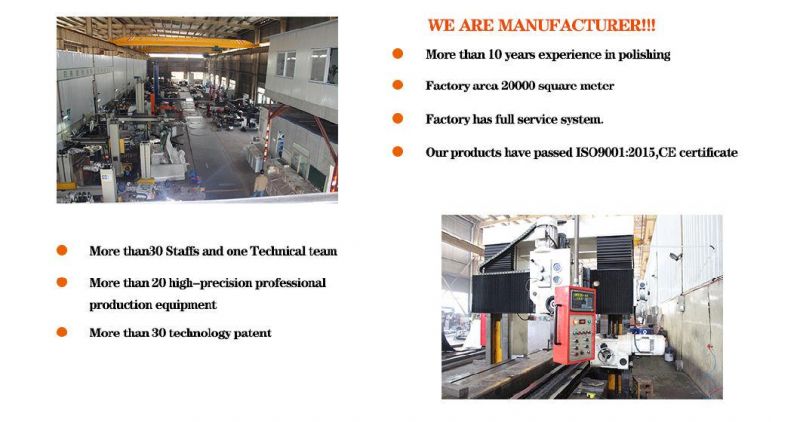

Anhui Xinyida Polishing Machine Co., Ltd.- Certification:ISO, CE

- Condition:New

- Voltage:380V

- Application:Stainless Steel Tank Polishing

- Transport Package:Wooden Cage with Protection Fixed by Sea

- Specification:3800*1600*3080

Base Info

- Model NO.:JY-HFPG

- Trademark:XYD

- Origin:China

- HS Code:8460902000

- Production Capacity:60sets,Month

Description

Max. Loading5T

Product Features:

Suitable for welding seam rolling and grinding of cycle welding parts. Thousand impellers, cloth wheels and nylon wheels are easily exchangeable to meet different polishing needs. An optional GHS dust collector is also available.

Packaging Details

1.PE film cover on machine.

2.Carton protection in Plywood case.

3.Or based on your requirements.

Port

Shanghai Port / Nanjing Port / Customer Demand

Technical Service:

1) Design rational process for customers according to their product positioning.

2) Help customers carry out technological transformation on the entire process to improve their production efficiency and capacity.

3) Customize polishing machine configurations and other manufacturing equipment for customers; provide spare parts to equipment users.

4) Help customers test, inspect and analyze new processes, and offer reasonable suggestions and improvement proposals.

5) Improve customer operation on polishing equipment; train their ability to use the equipment and improve their application efficiency.

6) Provide software train for customers and software design of special patterns.

7) Provide processing service for special products.

8) Provide professional designers of technological application to equipment users.

9) Provide technical advice, equipment maintenance and repair services.

After-sales Service:

• Free on-site installation and commissioning. (Customer provides air ticket + accommodation)

• 24-hour service hotline; providing free instruction and answering your questions.

• Life-time maintenance; one-year warranty. After warranty, we provide reasonable prices of spare parts and service.

• Once a year on-site free maintenance. (Customer offers airfare + accommodation, or completed by our local agent)

• Comprehensive and systematic technical training, to ensure your correct operation of the equipment.

Product Features:

Suitable for welding seam rolling and grinding of cycle welding parts. Thousand impellers, cloth wheels and nylon wheels are easily exchangeable to meet different polishing needs. An optional GHS dust collector is also available.

Packaging Details

1.PE film cover on machine.

2.Carton protection in Plywood case.

3.Or based on your requirements.

Port

Shanghai Port / Nanjing Port / Customer Demand

Technical Service:

1) Design rational process for customers according to their product positioning.

2) Help customers carry out technological transformation on the entire process to improve their production efficiency and capacity.

3) Customize polishing machine configurations and other manufacturing equipment for customers; provide spare parts to equipment users.

4) Help customers test, inspect and analyze new processes, and offer reasonable suggestions and improvement proposals.

5) Improve customer operation on polishing equipment; train their ability to use the equipment and improve their application efficiency.

6) Provide software train for customers and software design of special patterns.

7) Provide processing service for special products.

8) Provide professional designers of technological application to equipment users.

9) Provide technical advice, equipment maintenance and repair services.

After-sales Service:

• Free on-site installation and commissioning. (Customer provides air ticket + accommodation)

• 24-hour service hotline; providing free instruction and answering your questions.

• Life-time maintenance; one-year warranty. After warranty, we provide reasonable prices of spare parts and service.

• Once a year on-site free maintenance. (Customer offers airfare + accommodation, or completed by our local agent)

• Comprehensive and systematic technical training, to ensure your correct operation of the equipment.