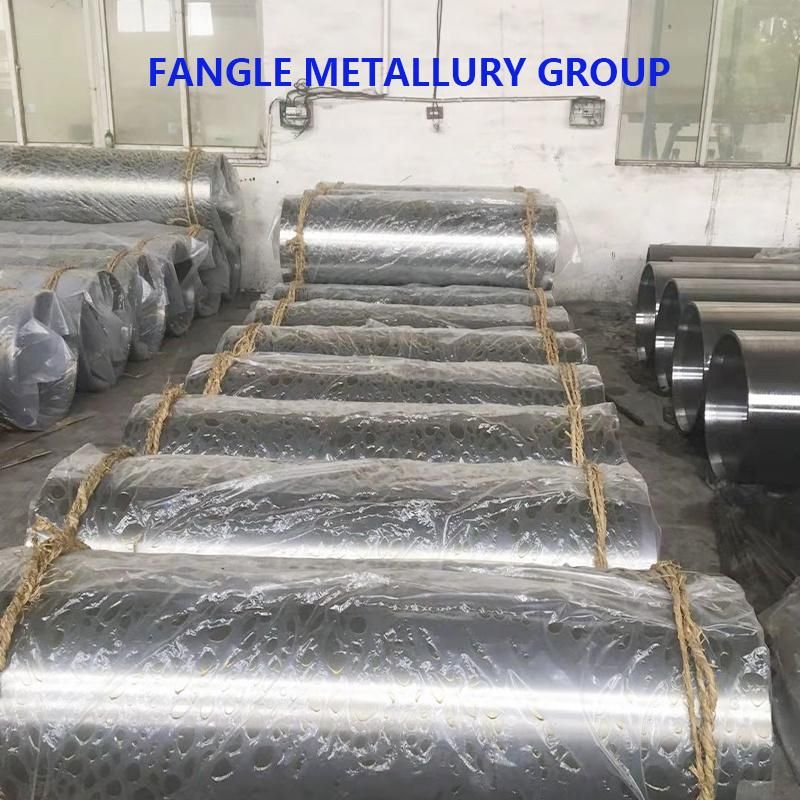

Steel Sleeve or Steel Spool for Aluminum Strips Rolling Mill Winder

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

- Material:Alloy

- Application:Winder of Aluminum Strip Rolling Mill

Base Info

- Model NO.:as the drawing

- Application Range:Aluminum Strip Mill, Steel Strip Mill

- QA+QC:Centrifugal Casted Type, Static & Dynamic Balance

- Inspection:Ut,Static and Dynamic Test

- Material Customized:Available

- Transport Package:Woodern Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- HS Code:84559000

- Production Capacity:20000 Tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Aluminum Strip Mill, Steel Strip Mill QA+QC Centrifugal Casted Type, Static & Dynamic Balance Inspection Ut,Static and Dynamic Test Material Customized Available Transport Package Woodern Case Specification Export package Trademark FANGLE Origin China HS Code 84559000 Production Capacity 20000 Tons/YearProduct Description

1. Scope of Usage and Classification

1-1.Scope of Usage

The steel sleeve will be used for the left & right winder of aluminum strip rolling mill

1-2. Size :as drawing

1-3 .Usage Conditions

As the customer requirement

2. Benchmark Related to Pilot Project

2-1. Hardness Inspection

Three point inspection: By using "Hardness Meter" device conduct inspection on either and middle of the sleeve, and collect data for three times from each test point and compare them with the theoretical value, then determine if it is qualified or not.

2-2. Size Inspection

By using steel tape measure, check the Out Diameter and Length, collect data and take the average to compare with the therotical value.

Inner Diameter will be checked by using inside micrometer, and data will be collected for three times from each test point and compare them with the therotical value, the reading accuracy will be one tenth.

3. Necessary Conditions And Quality Assurance

Material:Alloy forged steel

Roughness:as requirement

Mechanical properties :as requirement

When the Left / Right Winder create tension, the steel sleeve must be no deformation, rupture, or less inner / outer strength and abrasion that lead to slippage.

we will submit the Manufacturing Drawings before starting the manufacturing process, after the client verify it, manufacturing process can have a start. ( 3 Copies: 1 copy for returning, two copies for keeping)

4. Packaging and Transportation

4-1. Packaging:Each steel sleeve shall be packed in a wooden box, surface will be coated with grease oil, and covered with plastic materials fully in order to protect from rusting and surface corrosion.

4-2. Transportation: protected from any damages and deformations.

5. Quality Ensurance

we guarantee that performance of the steel sleeve meets the requirements and the related standards, and should satisfy the buyer with the usage for 12 months from date of acceptance.

Certificate: