Cemented Carbide Roller Ring for Rod Rolling Mill

Yantai Fangle Metallurgy Group Co., Ltd.- After-sales Service:Very Professional and Patient

- Warranty:Six Months

- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GB

- Customized:Customized

Base Info

- Model NO.:as the drawing

- Material:Alloy

- Application:Metal Processing Machinery Parts

- Application Range:Medium Rolling, Prefinishing and Finishing Mills

- Transport Package:Polywood Case

- Specification:Export package

- Trademark:FANGLE

- Origin:China

- Production Capacity:12000tons,Year

Description

Basic Info.

Model NO. as the drawing Material Alloy Application Metal Processing Machinery Parts Application Range Medium Rolling, Prefinishing and Finishing Mills Transport Package Polywood Case Specification Export package Trademark FANGLE Origin China Production Capacity 12000tons/YearProduct Description

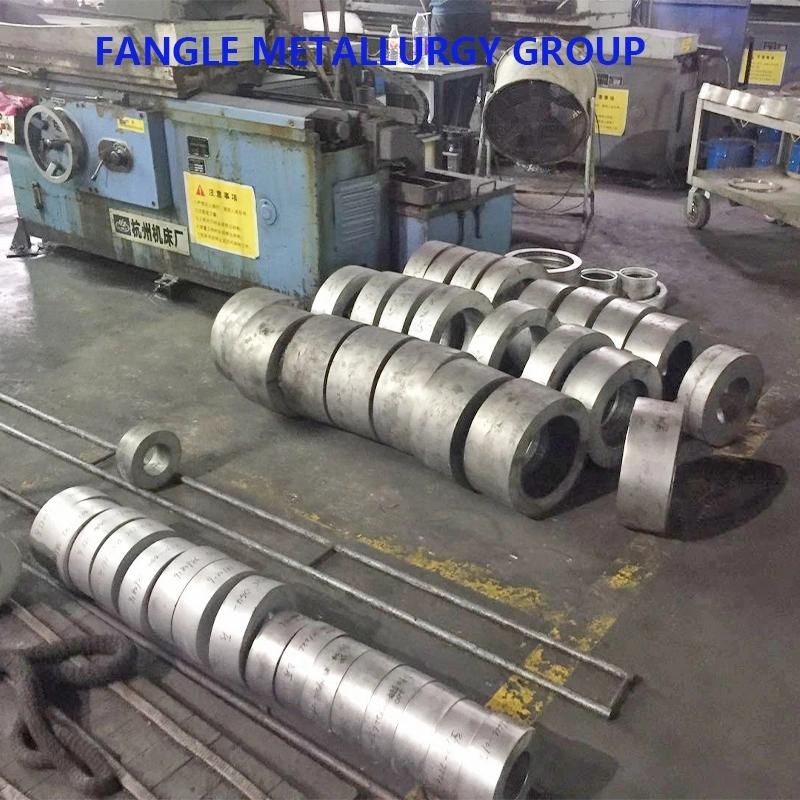

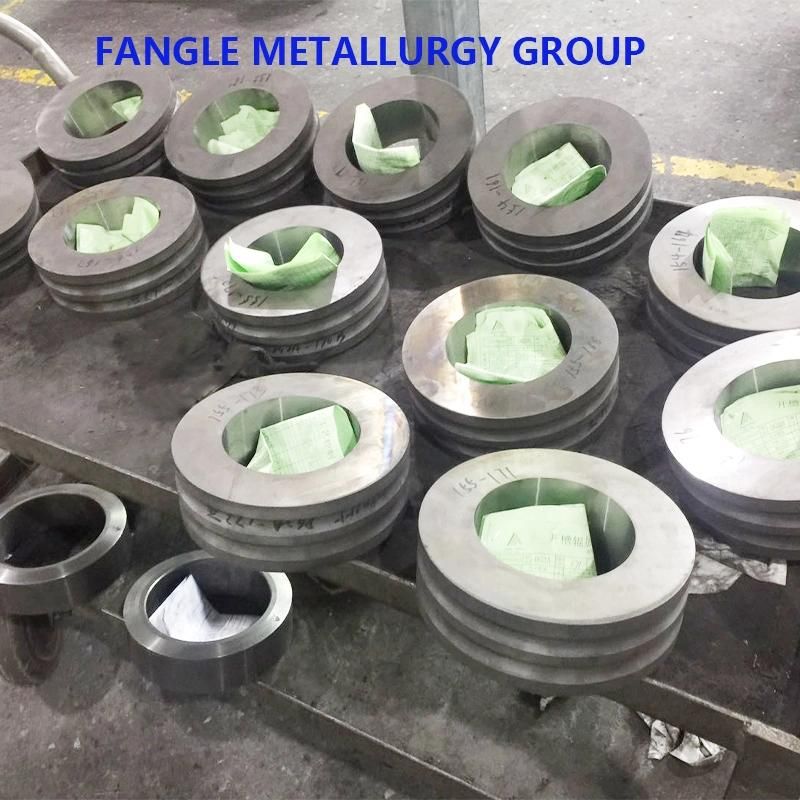

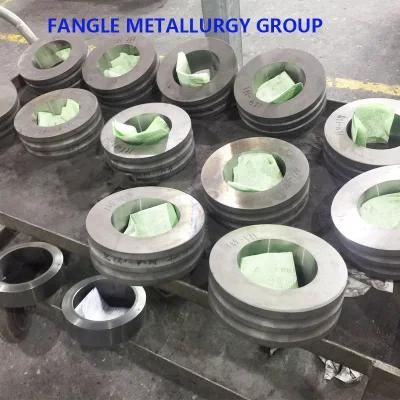

Cemented carbide rings (tungsten carbide rings) are widely used in high speed wire rolling lines. It is the new material and made by the production process of powder metallurgy. Cemented carbide rings are consisted of W and Co-Ni-Cr. According to the request of different stands for high speed wire rolling line, We adjusts the best proportion of W and Co-Ni-Cr to achieve good rolling tonnage.

We have three series.Grades series G have excellent property of crack resistance and heat resistance,good oxidation and corrosion resistance under high temperature,wide application.Grades series T have superior wear resistance,oxidation resistance,good abrasion resistance,corrosion resistance under high temperature,applicable for alloy steel wire rod production.Grades series M have excellent crack resistance and impact resistance,corrosion resistance,especially applicable for production of alloy steel wire rod. All the three series could bring good rolling tonnage for customer. We will give best suggestion to our customers.

Using solid cemented carbide rolls for intermediate, pre-finishing

and finishing stands for hot rolling.

Max outer diameter up to 520mm and width 150mm

It can roll continuously for 24 hours

Less downtime comparing with cast rolls.

Pass life is more 20 times than ordinary cast rolls

Pass and notching machined upon customers' requests.