Dixin Roof Panel Steel Rolling Forming Machine/ Trapezoidal Metal Roof Sheet Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Type:Mechanical Press

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:plate rolling machine

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Mode:Plate Rolling Machine

- Feeding Width:1200mm

- Finial Product:988-76-18 Corrugated Roof Panel

- Main Motor:4 Kw

- Pump Motor:4 Kw

- Shaft Diameter:75mm

- Forming Steps:15 Rows

- Main Frame:350 H,U Steel

- Forming Speed:8-12 M,Min

- Machine Size:7200mm*1400mm*1200mm

- Transport Package:Waterproof Package

- Specification:DX-988-76-13

- Trademark:DIXIN

- Origin:China, Hebei

- HS Code:845522

- Production Capacity:50 Sets Per Piece

Description

Basic Info.

Model NO. plate rolling machine Customized Customized Advantage Use Widely Condition New Mode Plate Rolling Machine Feeding Width 1200mm Finial Product 988-76-18 Corrugated Roof Panel Main Motor 4 Kw Pump Motor 4 Kw Shaft Diameter 75mm Forming Steps 15 Rows Main Frame 350 H/U Steel Forming Speed 8-12 M/Min Machine Size 7200mm*1400mm*1200mm Transport Package Waterproof Package Specification DX-988-76-13 Trademark DIXIN Origin China, Hebei HS Code 845522 Production Capacity 50 Sets Per PieceProduct Description

Dixin Roof Panel Steel Rolling Forming Machine/ trapezoidal metal roof sheet forming machine

1). To design and make the best roll forming machine, we took EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 17+ years experience;

3). We achieves that the machine capacity is double of the competitors;

4). The machine working speed can be 15m/min;

5) . Very easy to install and operate the roll forming machine.

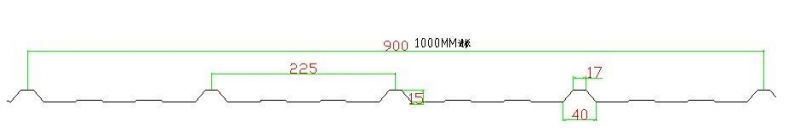

1.Panel drawing as customers request .

2.Equipment detailed parameters:

| 1.Processing material | aluzinc/galvanized steel/colored steel coil |

| 2.Material thickness | 0.3-0.8mm |

| 3.Feeding width: | 1000mm |

| 4.Effective width | 900mm |

| 5.Main motor power | 4kw |

| 6.hydraulic pump power | 4kw |

| 7. Shaft diameter | 75mm |

| 8.Forming steps | 13steps |

| 9.Main frame | 300H Steel frame |

| 10. Side plate thickness | 16mm |

| 11.Roller material | 45# forged steel, with hard chrome plating |

| 12.Control systerm | PLC control system with touch screen |

| 13.Cutting blade material | Cr12 |

| 14.Working speed | About 10-12m/min |

| 15. Transmission way | 1 inch chain drive |

| 16. Machine size (mm) | About 6800*1500*1400mm |

| 17. Machine weight | About 2.5ton |

| 18.Power supply | 380v,3phase,50hz or accodring to customer request |

3.Working flow:

Uncoiler-- roll forming machine-- PLC control box-- hydraulic cutter- receiving table

4.Some machine pictures for your reference.

5.Packing and shipping details

1.Main Galvanized Aluminium IBR Roof Sheet Roll Forming Making Machine and un-coiler is nude packing (If you need, we can also packed it with water-proof plastic)

2. PLC control system and motor pump are packed with water proof paper,spare parts in carton box.

3.One set of machine needs a 40' container to shipping.

FAQ

1. Q:Are you manufacturer?

A:Yes, we focus on cold roll forming machine manufacture over 12 years.

2. Q: if you can accept OEM? Design and manufacture according our photo.

A: Yes, we can accept OEM,we owned expert engineer team, professional design CAD drawings and use famous brand components according your demands.

3. Q:What's the warranty for your machine?

A: we provide 2years guarantee and provide lifetime technical support.

4. Q:How many workers is needed for the machine operation

A: One worker is enough, the machine use automatic PLC control system.

5. Do you have after sales support?

A: Yes,Our engineer can supply remote-video technical support and online support teach your worker.

6. Q.Can you be responsible for transport?

A.Yes,we owned expert export team, we can arrangement for you to your destination port or address.

7. Q:What service can you provide before order?

A:About the pre-sale service, We provide professional solutions according your demands,such as design,technical parameter,delivery flow etc. At the same time, we can supply invitation letter for your visit our factory and showing the machine operationfor you .

8. Q: What is the after- sale service?

A: we will supply lifetime technical support,quick-wear parts within 2years,Also can provide field maintenance and repair service.

9. Q:Any other service?

A: We can help you purchase raw material for machine,help you check ship date,update for you ship date etc