Customized Different Shape Ball Stud Bracket for Auto Industry

NINGBO JH MACHINERY CO., LTD.- Condition:New

- Certification:ISO9001

- Standard:GB, Non-Standard

- Customized:Customized

- Material:Stainless Steel

- Application:Metal Cutting Machine, Metal Processing Machinery Parts, Metal Coating Machinery

Base Info

- Model NO.:JH-M054

- Color:Metal Luster or Per Customer′s Request

- Type:Non-Standard

- Size:Per Customer′s Request

- Surface Treatment:Zinc Plated or Per Customer′s Request

- Thread:Per Customer′s Request

- Transport Package:Bulk Pack in Plastic Bag, Wooden Pallet

- Specification:non-standard

- Trademark:OEM

- Origin:Ningbo, China

- Production Capacity:5000~10000 PCS,Month

Description

Basic Info.

Model NO. JH-M054 Color Metal Luster or Per Customer′s Request Type Non-Standard Size Per Customer′s Request Surface Treatment Zinc Plated or Per Customer′s Request Thread Per Customer′s Request Transport Package Bulk Pack in Plastic Bag, Wooden Pallet Specification non-standard Trademark OEM Origin Ningbo, China Production Capacity 5000~10000 PCS/MonthProduct Description

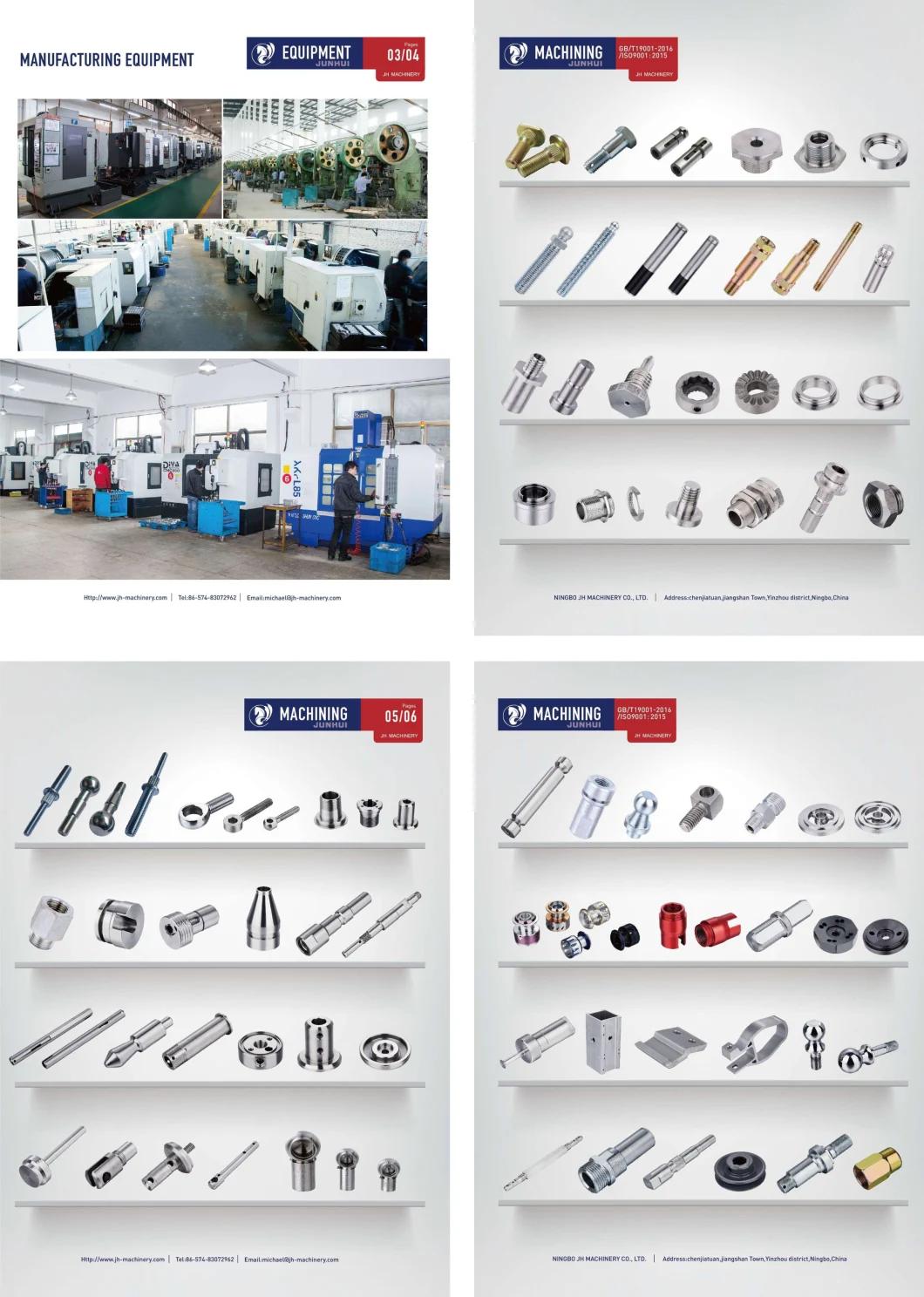

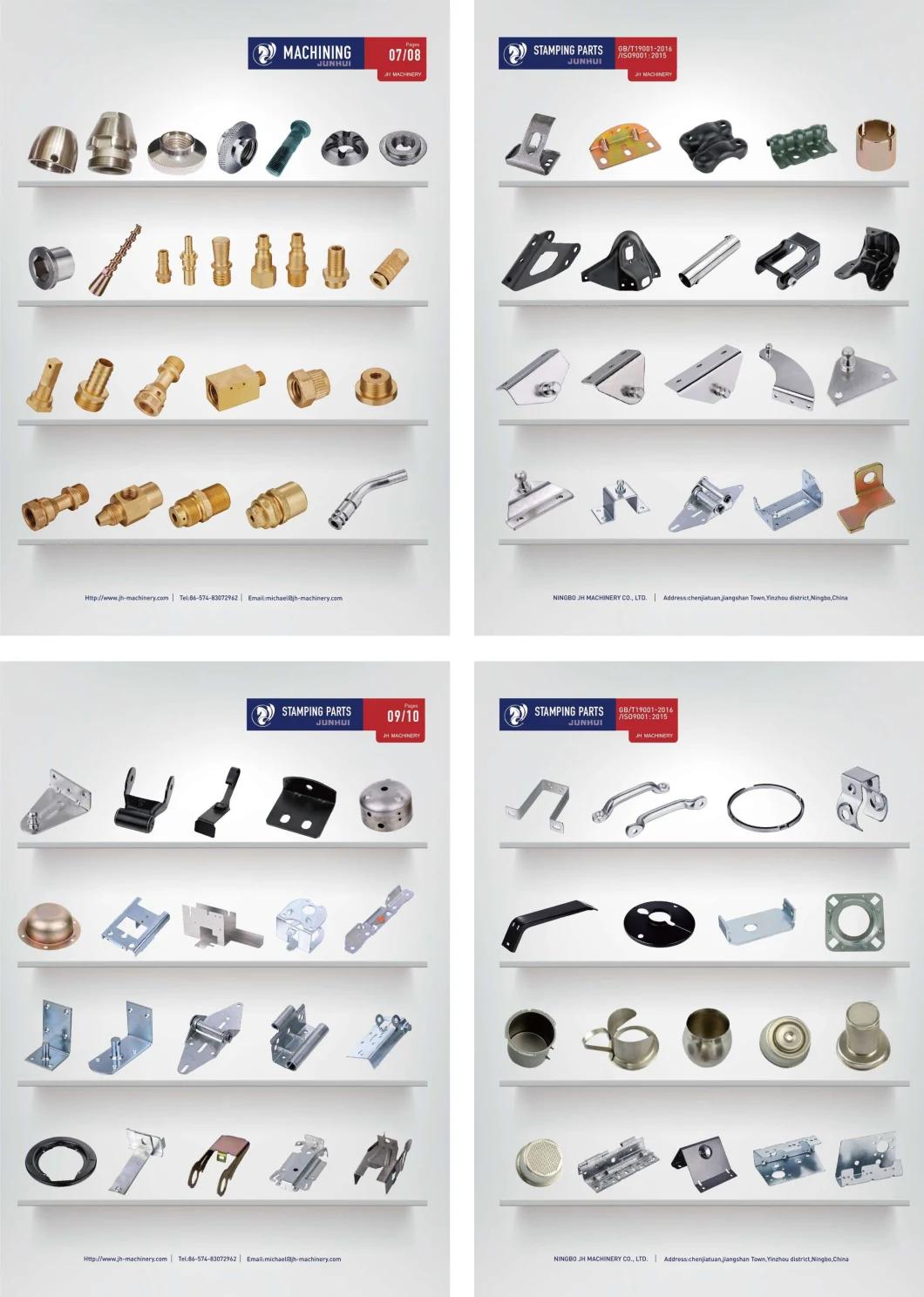

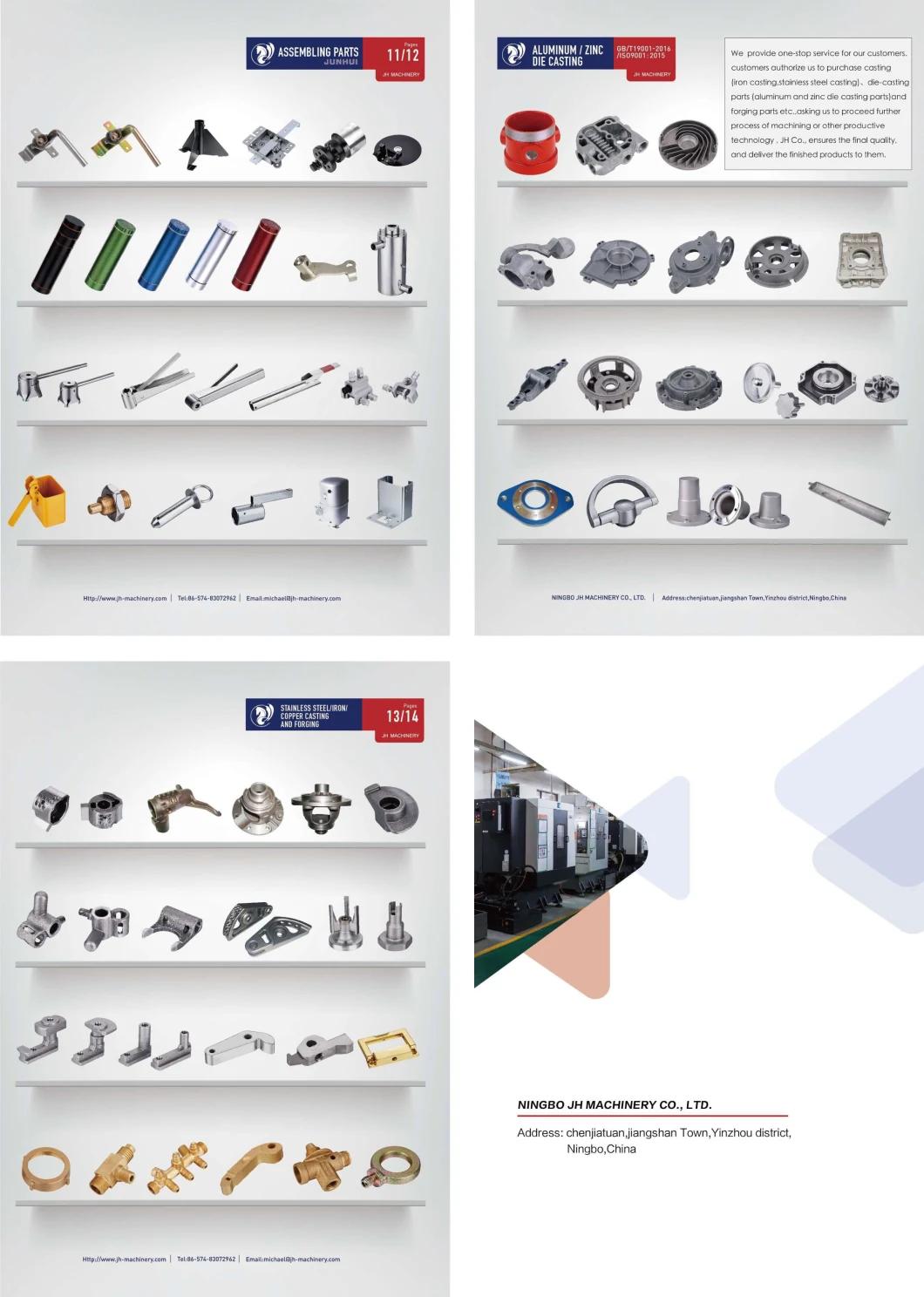

JH Introduction&Partial Products DisPlay

JH Advantages

JH Advantages| Price | Reasonable and competitive | Since we have established almost 10 years, we have plenty of experience in quoting and we always could get the raw material with lowest price. |

| Delivery | Timely | Family Business with more flexible delivery than other suppliers |

| Service | One-to-One service | We will appoint a special personnel to serve you, including quote, quality ,financial, after-service and so on. You won't be bothered and get confused with different people.Make you feel more comfortable. |

| Transportation | Convenient | We have our own truck and quite close to Beilun Deep-water Harbor. It's location advantage that can help you save cost and avoid lots of unexpected problem. |

1.What are the production capacity of your company?

a). fabrication works include precision stamping, deep drawing, fine blanking, cnc punching, cnc bending, laser cutting, flame cutting, cnc milling, cnc turning, tube bending, aluminum extruding, welding, die casting, etc.

b). Metal materials include stainless steel, iron, carbon steel, spring steel, aluminum, copper, brass, bronze etc.

2.What equipments do you own?

a). Punch Press, Progressive Die

b). Welding: Carbon dioxide welding, spot welding, tig welding, automated robotic welding.

c). Machining: CNC lathe and machine centers, light machines(drilling, milling and tapping).

d). Surface treatment: Polishing, Deburring

3.What finishes can you provide?

The finishes which we could provide is powder coating, painting, galvanizing, baked enamel, anodizing finish, and other plating finishes.

4.How can you guarantee the quality?

Quality control department build the control plan before starting the project, the strict inspection will be applied throughout the whole production.

Contact us freely and we would provide you our best solutions!