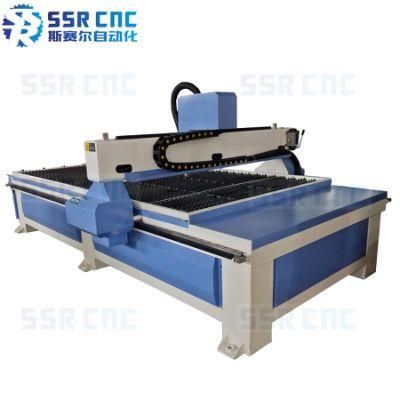

Plasma Cutting CNC 100A Machine High Plasma Power Machine Made in China

Shandong SSR CNC Equipment Co., Ltd.- After-sales Service:24 Hours on Line Support

- Warranty:2 Years

- Customized:Customized

- Layout:Coaxial

- Cutting Material:Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

- Automatic Grade:Automatic

Base Info

- Model NO.:SSR-1530P

- Power Source:Electric

- Cutting Mode:Plasma Cutting

- Machine Model:SSR-1530p

- Machine Structure:Welded Steel

- Machine Dimensions(Length * Width * High:Machine Dimensions(Length * Width * High)

- Table Structure:Sawtooth

- X Y Z Axis Guides:Taiwan Imported Hiwin Square Rail

- Plasma Source:Huayuan Lgk 63A Series (Options100A , 120A , 160A

- Transport Package:Wooden Package

- Specification:1500mm*3000mm

- Trademark:SSR CNC

- Origin:China

- HS Code:8456401000

- Production Capacity:300 Sets,Month

Description

Features

Product Parameters

Detailed PhotosWorking SamplesFAQ

What types of material can I cut with my CNC plasma?

Due to the technology advantages of our plasma cutter, we are able to provide you with more capabilities than typical plasma cutting machines. Our plasmas are most commonly used to cut steel, aluminum, brass, copper, and other conductive metals.

Please Note proper safety measures should be considered and taken for various materials. See the Cutters Recommendations or ask us for limitations.

How To Choose The Right CNC Plasma Cutter?

1. It is necessary to figure out the material and thickness to be cut. This is how to determine the cutting method.

For metal with a thickness of no more than 10mm, please choose plasma cutting,

For metals with a thickness of 10-30mm, plasma cutting and flame cutting can be used.

It is recommended to perform flame cutting on metals above 30mm.

2. Need to figure out the effective cutting width and length. According to the effective cutting, the size determines the product model range.

3. Determine the required structural form. CNC plasma cutting machine has a variety of structural forms, we have desktop type and portable type.

4. Determine the number of cutting torches needed and how to adjust the height. Two or more cutting torches using the same cutting method can cut a pattern at the same time, which can improve work efficiency (that is, the working efficiency of the two cutting torches is twice that of the cutting torch with the same pattern) (flame and plasma cutting) Torches cannot be used at the same time).

5. Requirements for the system and drive mode. You need to know the cutting system you need. The drive mode is stepper motor drive or servo motor drive.

6. The choice of power supply brand. The cutting quality and cutting price of different brands of power supplies are also different, and the choice of power supply brands should be determined according to needs.