OEM Custom Stainless Steel/Aluminium/Copper Machining Machinery Spare Part

Qingdao Tongyunxin Industry and Trade Co., Ltd.- Condition:New

- Certification:RoHS, ISO9001, ISO14001, BV , TUV

- Standard:GB

- Customized:Customized

- Material:Iron

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Transport Package:Pallet

- Trademark:TYX or OEM

- Origin:China

- HS Code:8451900000

Description

Basic Info.

Transport Package Pallet Trademark TYX or OEM Origin China HS Code 8451900000Product Description

product description| Material | Stainless steel, carbon steel, alloy steel, aluminium, brass, bronze and plastic (according to customer's requirements) |

| Processing | CNC machining, CNC milling and turning, drilling, grinding, cutting, stamping, tapping |

| Surface Treatment | Anodizing ,Heat treatment, polishing, powder coating, galvanized, electroplating, spraying, and painting |

| Dimensions | According to customer's drawing |

| File Format | PDF/JPEG/AI/PSD/CAD/Dwg/Step/LGS |

| Inspection | 100% inspection and random inspection before shipment, with QC passed label |

| Application | industry machinery, railway traffic equipments, automation machine, household appliance, mould manufacture and more. |

| Processing Equipments | CNC lathing machine, CNC gantry milling machine, CNC horizontal boring machine, drilling and grinding machine, cutting machine, welding machine, polish machine |

| MOQ | 1pcs |

| Packing | pallets or customized |

| Trade Terms | FOB, CIF, CFR or as per customers' request |

| Payment Terms | Larger amount by T/T with 30% as deposit,70% before shipment |

| Delivery Time | For sample 5-7 days, for mass productiong depend on the quantity |

| Shipping Ports | Qingdao |

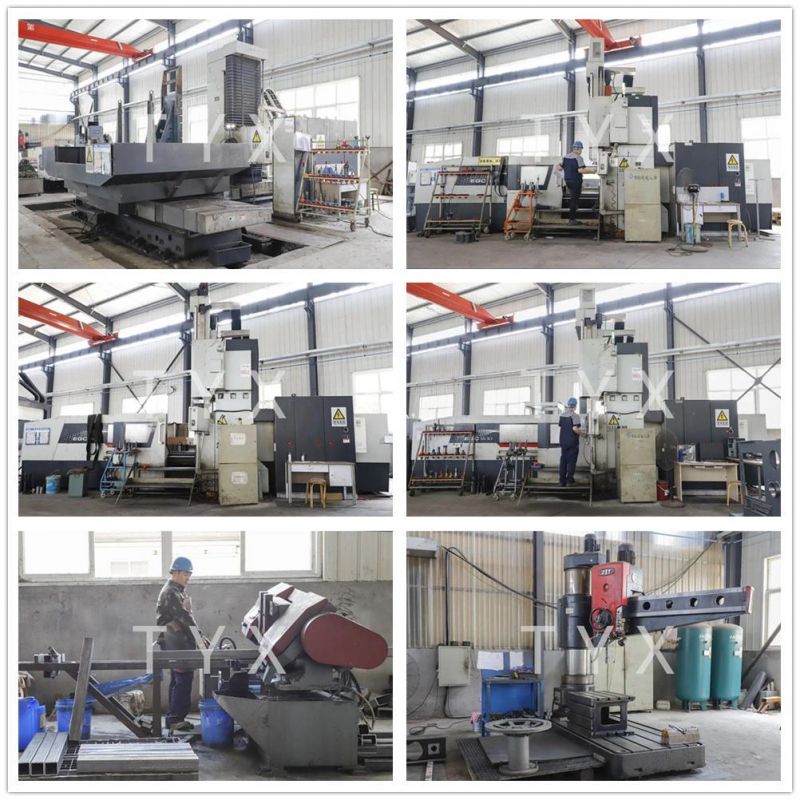

factory overview

Qingdao Century Tongyun Industry Developing Co., Ltd. , belongs to Qingdao Century Tongyun Group, set up in 2012, main business in mould making, mechanical equipment machining, installment and maintance, especially for the plastic mould and metalplate mould, widely used in household appliance and automobile. We already owned the advanced designing and machining technics in the worldwide market. And been the superior supplier of traffic equipment processing from CRRC.

By the integrated and scientific quality management system, certification system of GB/T19001-2008/ ISO9001: 2008 got in Jan. 2014, for the long-term cooperative supplier with Haier and Hisense, and win the good reputation in technics, quality as well as production efficiency.

There are kinds of CNC equipments total for 70 sets, including the large precision machining equipments,

3 sets of large gantry machining centre(3200*1850*800),

1 set of horizontal boring machining center(3000*2000*1600),

1 set of precision deep hole drilling(1500*1000*1500),

1 set of deep hole drilling(1500*1000*1300),

2 sets of slow feeding wire cutting machine(800*500, 500*350),

2 sets of multi-function gas shielded welder(NBC-500N),

3 sets of digital inverse argon arc welding machine(WS-315),

2 sets of EDM(1500*900*600, 1000*500*400).

As well as other general CNC, vertical milling machine, flat grinder, large sawing machine, planer, bench drill, large rock drill, hardness tester, trilinear coordinates measuring instrument etc.

product show

production equipment

Certification

How to place your order :

1.Please send us your drawings( 2D&3D) or sample.

2.Our engineers will design and submit competitive quotation for you.

3.Confirm sample order and making after you approve the quotation and submitting for your inspection.

4.Confirm production order after you approve samples.

5.Payment and shipping terms are negotiable.

1)favourable price

2)High quality control : 100% full inspection before shipment

3)High precision, tolerance can be ± 0.005mm

4)Fast lead time (5-7days for samples, 20-25 days for mass production)

5)Non-standard/customized service

6)No MOQ, 1pcs is acceptable.

7)Factory ISO 9001, ISO14001certification, BV and TUV certification, ROHS system.

9)Professional export packing.

Contact info.