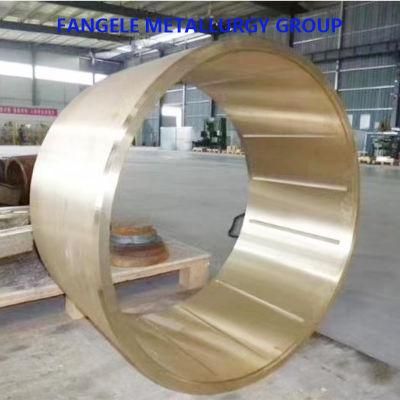

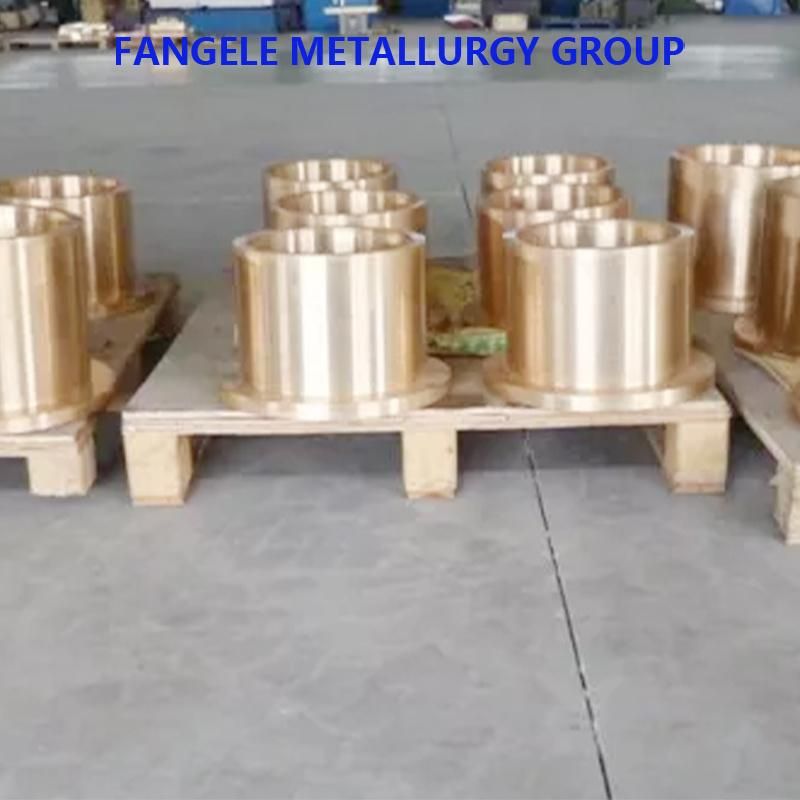

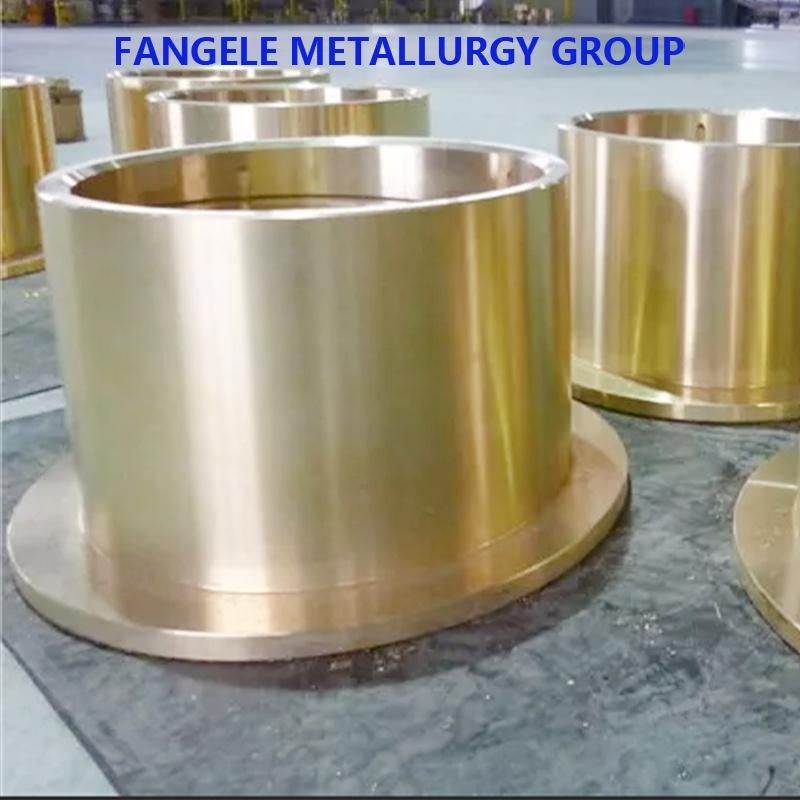

Crusher Copper Sleeve

Yantai Fangle Metallurgy Group Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, GB

- Customized:Customized

- Material:Copper

- Application:Metal Processing Machinery Parts

Base Info

- Model NO.:as the drawing

- Application Range:Crusher Spare Parts

- Transport Package:Seaworthy Package

- Specification:as the requirement

- Trademark:FANGLE

- Origin:China

- Production Capacity:50000 Tons,Year

Description

Basic Info.

Model NO. as the drawing Application Range Crusher Spare Parts Transport Package Seaworthy Package Specification as the requirement Trademark FANGLE Origin China Production Capacity 50000 Tons/YearProduct Description

Crusher copper sleeveDescription

Tin bronze is generally used as the material for the copper sleeve on the baffle wheel of rotary kiln or crusher copper bush. Tin bronze has tin as its main alloying element. Compared with other bronzes, tin bronze is relatively corrosion resistant and has high cost performance in rotary kiln.This alloy has high mechanical properties, wear reduction properties and corrosion resistance, free cutting, good brazing and welding properties, small shrinkage coefficient, no magnetism.

The bearing bush of rotary kiln is usually made of aluminum bronze or zinc-based alloy.Aluminum bronze has high mechanical properties, good wear resistance in air, fresh water and sea water, good casting performance, compact structure, high air tightness, good wear resistance, not easy to brazing, casting performance is still good.It is mainly used in important castings requiring high strength and good corrosion resistance.

Zinc-based alloy is an alloy made of zinc and other elements.The alloy elements commonly added in zinc-based alloys include aluminum, copper, magnesium, cadmium, lead, titanium, etc.Zinc-based alloy has the advantages of low melting point, good fluidity, easy welding, brazing and plastic processing, corrosion resistance in the atmosphere, and easy recovery and remelting of deformity materials.

Compared with babbitt alloy, it has the advantages of higher strength and toughness, lower specific gravity and wider application range.The alloy can be used for heavy, thick, large parts, low temperature, alternating and impact loads and other harsh conditions.

Parameters

| Material | Brass bush, Tin bronze bush, Lead bronze bush, Aluminum bronze bush etc |

| Standard | As customized requirement |

| Fearture | 1. High load capacity and good anti-wearing 2. Low coefficients of friction 3. Good heat conductivity 4. High corrosion resistance 5. Long life and maintenance-free 6.No contaminant by oil or grease |

| Process | Melting -Centrifugal casting copper bush-Machining-inspection-package |

| Quality assurance | MT certificate ,Dimension certificate etc |

| Tolerance | Roundness::+/- 0.01mm. Flatness:+/- 0.005mm. Height and length:+/- 0.01mm. |

| Lead time | According to required time |

Prodcuts Show

Customer Visit