Powder Coating Production Line System for Metal Parts

Zouping Hongyuan Eco-Friendly Mechanical Technology Co., Ltd.- After-sales Service:Available

- Warranty:12month

- Type:Coating Production Line

- Coating:Powder Coating

- Substrate:Ceramic

- Certification:CE, ISO, SGS

Base Info

- Model NO.:HY-PLD

- Condition:New

- Powder Coating Spray Gun:Manually or Automatically

- Painting Method:Automatically or Manually

- Powder Coating Spray Booth:Automatically or Manually

- Powder Coating Curing Oven:Batch Type, Air Curtain Type, Bridge Type

- Transfer Equipment:Automatically or Manually

- Heating System:Gas, Diesel, Electricity

- Powder Recovery System:Fcm, Rcm, Large Cyclone, Small Cyclone

- Pretreatment:with or Without

- Control System:English Panel, Other Language for Option

- Load Capacity:as You Required

- Transport Package:Standard Package for Sea Shipment

- Specification:40HQ for FCL

- Trademark:N,A

- Origin:Shandong, China

- Production Capacity:100 Set Per Month

Description

Basic Info.

Model NO. HY-PLD Condition New Powder Coating Spray Gun Manually or Automatically Painting Method Automatically or Manually Powder Coating Spray Booth Automatically or Manually Powder Coating Curing Oven Batch Type, Air Curtain Type, Bridge Type Transfer Equipment Automatically or Manually Heating System Gas, Diesel, Electricity Powder Recovery System Fcm, Rcm, Large Cyclone, Small Cyclone Pretreatment with or Without Control System English Panel, Other Language for Option Load Capacity as You Required Transport Package Standard Package for Sea Shipment Specification 40HQ for FCL Trademark N/A Origin Shandong, China Production Capacity 100 Set Per MonthProduct Description

Choose the best powder coating project for you according to your actual requirements, Please see the following steps:PS: If you want to save the one-time investment for the equipment, we could guide you to make the parts of the equipmentby yourself to ensure the performance.

1st step: Please confirm which kind of powder coating project you need(manually, semi-auto or fully automatically).

2nd step: Please confirm the following parameterswhen confirm the detailed project.

3rd step: after get the information about the 1st step and 2nd step, we will design the best powder coating spray plan for you according to the info you provided.

1st step: Regular modes for choice and suggestion:

1.small output and few investment about the equipment: Mode A(every part will be by manually).

2. Large volume output, just one kind of workpiece, suggest Mode C(every part would be automatically except the manually painting and the pretreatment) and Mode D(every part will be by automatically excluding the pretreatment).

3. Large output, just one kind of workpiece, advise Mode D(every part will be by automatically exclude the pretreatmenT) and Mode B (every part will be by automatically).

4. Large output, and large size of the workpiece(such as profile), advise Mode E(manually painting and the batch type curing and the conveyor line) and Mode C(every part would be automatically except the manually painting and the pretreatment).

2nd step: the parameters we need to know and consider for design:

1. The largest size of work piece, length, width, height and thickness.

2. The max weight of the work piece

3. Is there any requirements about the suspension of the work piece?(confirm during following email)

4. The material of the work piece

5. The anticipate output for the largest size of the work piece(how many pieces in 8 hours)

6. The clear length, width and height of the factory available for the powder coating line

7. The heating power: Liquefied Petroleum Gas, Liquefied natural gas, diesel, or electric? The LPG and LNG are the most popular choice.

8. Do you need to change colors every day? How many colors do you have in total?

9. Do you need automatic painting or manual painting?

10. Do you need pre-treatment process? If yso, you prefer spray pre-treatment or bath pre-treatment?

11. The local electricity conditions(_V/3Phase, ----V/1phase, frequncy, 50Hz or 60Hz)

12. Do you have any special requirements about the package?

Advantages

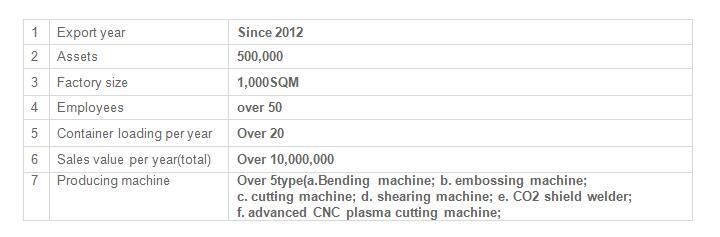

Production area and equipment for Powder Coating Production Line System for Metal Parts

Package Show of Powder Coating Production Line System for Metal Parts

Certificate of our product and company

Our Team is serving you at any time

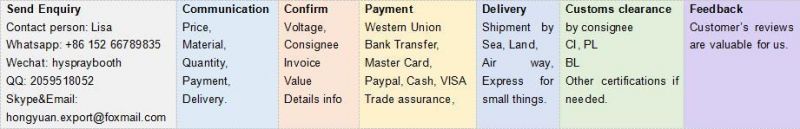

Send us inquiry for more info about Powder Coating Production Line System for Metal Parts

Without communication, there is no relationship;

without respect, there is no love;

without trust, there is no reason to continue!

Happy new year to you all! Wish the best to your family!