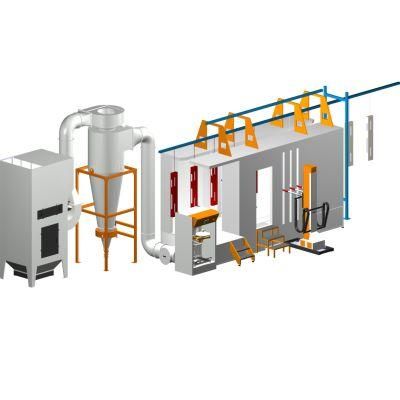

High Quality Powder Coating Machine with Overhead Conveyor

Yangzhou OURS Machinery Co., Ltd.- Type:Coating Production Line

- Coating:Powder Coating

- Substrate:Steel

- Certification:CE, ISO

- Condition:New

- Power:50kw-200kw

Base Info

- Model NO.:OURS-2014

- Voltage:380V,220V,110V

- Warranty:1 Year After Acceptance

- Size:up to The Client

- Transport Package:Standard Container

- Specification:CE, SGS, ISO

- Trademark:N,M

- Origin:China(Mainland)

- HS Code:8424200000

- Production Capacity:60 Sets,Year

Description

Basic Info.

Model NO. OURS-2014 Voltage 380V/220V/110V Warranty 1 Year After Acceptance Size up to The Client Transport Package Standard Container Specification CE, SGS, ISO Trademark N/M Origin China(Mainland) HS Code 8424200000 Production Capacity 60 Sets/YearProduct Description

High Quality Powder Coating Machine with Overhead ConveyorProduct advantages:

1.Corrosion resistance

2.High efficiency

3.Prolong the life of workpiece

4.Lower cost

Operating principle:

The powder coating machine sprays the powder paint on the surface of the workpiece which will adsorb on the surface evenly to powder coatings under the effect of static electricity. And the powder coatings will level and solidify under high-temperature baking to the final coating. This technology is superior to others in the field of mechanical strength, adhesive force, corrosion resistance and aging resistance.

Technological process:

Loading--Predegreasing--Degreasing--Water rinse 1--Water rinse 2--Surface conditioning--Phosphating--Moisture drying--Natural cooling--Powder spraying--Powder curing--Natural cooling--Unloading

| Main parts of powder coating line: |

| *Pre-treatment system: Sand-blasting, Shot blasting and dipping pre-treatments are available; |

| *Drying oven: Drying oven which is used for drying the water after pre-treatment is designed according to customer actual conditions. Electricity, gas, diesel are all available for the heating energy; |

| *Powder coating system: Automatic spray reciprocator , Manual spray equipment and Semi-auto (Auto-spraying with manual repairing spraying) are for your choice; |

| *Powder recycling system: Cyclone equipment and cartridge filters is customized and introduced according to actual requirement by customer; |

| *Curing oven: Tunnel curing oven, bridge type curing oven, Electric power heating curing oven, Gas-heating curing oven, Diesel heating curing oven, High-temperature and lower-temperature curing ovens are available for fitting your sole factory; |

| *Conveying system: Various design according to different requirement by customer on the basis of customers' workpiece and output information, including plate conveyor, chain conveyor, overhead conveyor etc.; |

Package and shipment:

OURSCOATING quantifies the production of standard coating equipment and one-to-one service is our important and special sale method. For special requirements of different customers from different countries, we will design based on the workshop size, the workpiece size and weight, the types of paint, the budget level, etc., and will solve all the problems 100% from your point of view.

OURSCOATING is the expert manufacturer you can never miss! If you are interested in our products, pls feel free to contact us.