Minitype Standing Seam Roofing Machine with Adjustment Forming Panel Rolling

Xiamen Xinhonghua Machinery Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Tire Mold Forging

- Power Source:Electric

- Feature:Automation

- Certification:SGS

- Warranty:12 Months

Base Info

- Model NO.:KLS25-200-650

- Customized:Customized

- Advantage:Work Flexible

- Condition:New

- Dimension:2000*1100*1200mm

- Weight:1500kgs

- Motor Power:2.2kw

- Power for Hydraulic Forming Cutter:0.75kw

- Forming Steps:6

- Thickness:0.5-1.0mm

- Forming Speed:6-8m,Min

- Voltage:380V,50Hz,3pH

- Delivery Time:Delivery Immediately After The Machine Is Assemble

- After-Sales Service:Engineers Available to Service Machinery Overseas

- Transport Package:Nude in Container

- Trademark:XHH

- Origin:Xiamen of China

- HS Code:84552290

- Production Capacity:20 Sets,Month

Description

Basic Info.

Model NO. KLS25-200-650 Customized Customized Advantage Work Flexible Condition New Dimension 2000*1100*1200mm Weight 1500kgs Motor Power 2.2kw Power for Hydraulic Forming Cutter 0.75kw Forming Steps 6 Thickness 0.5-1.0mm Forming Speed 6-8m/Min Voltage 380V/50Hz/3pH Delivery Time Delivery Immediately After The Machine Is Assemble After-Sales Service Engineers Available to Service Machinery Overseas Transport Package Nude in Container Trademark XHH Origin Xiamen of China HS Code 84552290 Production Capacity 20 Sets/MonthProduct Description

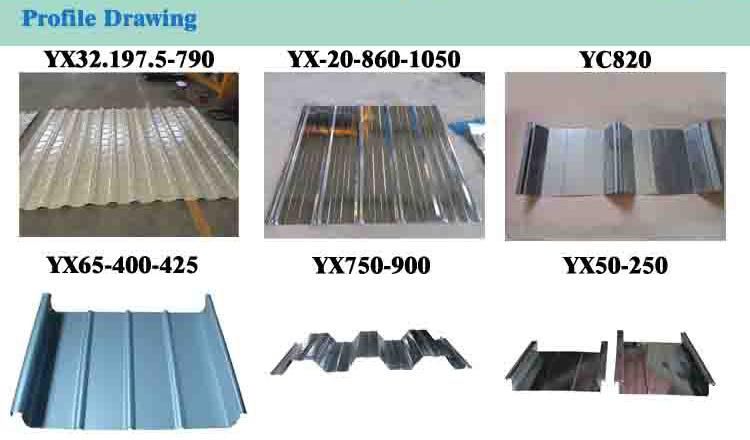

KLS25-200-650 Roof Panel Forming Machines with Adjustment detailed informations are as follows:

Main Accessories

(1). Main Standing Seam Roofing Machine;

(2). 3 Tons Manual Uncoiler;

(3). PLC Computer Controlling System for Touch Screen;

(4). Hydraulic System;

(5). Device for adjusting variable width;

(6). Hydraulic Forming Cutter;

(7). Run out table (3 PCS);

(8). Protective Cover;

(9). Tools;

(10). Hand Seamer (2 PCS);

(11). Operation Manual.

| 1. | Size | 2000*1100*1200mm |

| 2. | Weight | 1500KGS |

| 3. | Motor Power | 2.2KW |

| 4. | Power for hydraulic forming cutter | 0.75KW |

| 5. | Voltage | 415V/50HZ/3PH |

| 6. | Forming Steps | 6 steps |

| 7. | Thickness for steel | 0.5-0.8mm |

| 8. | Thickness for Aluminum | 0.5-1.0mm |

| 9. | Thickness for common use and test | 0.7-0.9mm |

| 10. | Forming Speed | 6-8m/min |