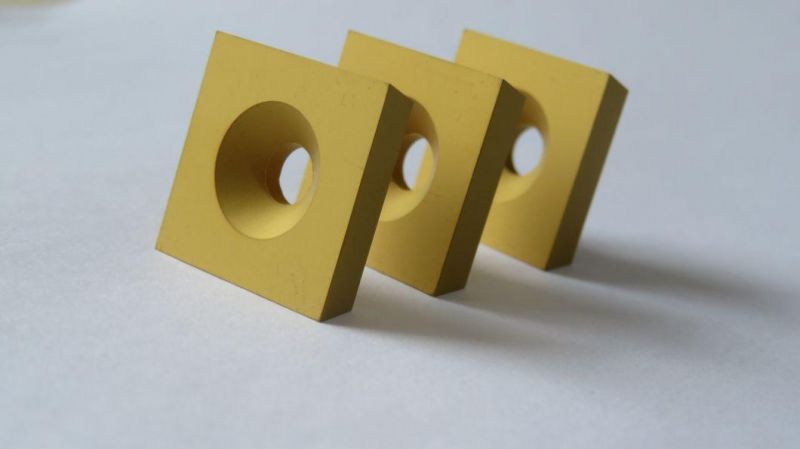

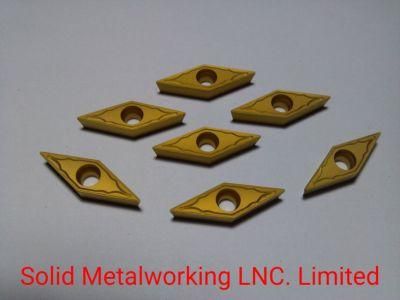

Carbide Turning Inserts with excellent edge strength

Solid Metalworking LNC. Limited- Customized:Non-Customized

- Material:Metal

- Application:Metal Cutting Machine

- Code:Tnmg160404

- Coating:CVD

- Chip-breaker:Special design

Base Info

- Model NO.:ISO-OEM

- Customization:Available

- Standards:P

- Style:Universal Tool

- Structure:Special Type

- Cutting Process:Turning Tools

- Work Type:External Work

- Transport Package:Plastic Box

- Specification:ISO

- Trademark:Excelledge

- Origin:Chengdu, China

- HS Code:82080100

- Production Capacity:50, 000 PCS,Month

Description

Basic Info.

Model NO. ISO-OEM Customization Available Standards P Style Universal Tool Structure Special Type Cutting Process Turning Tools Work Type External Work Transport Package Plastic Box Specification ISO Trademark Excelledge Origin Chengdu, China HS Code 82080100 Production Capacity 50, 000 PCS/MonthProduct Description

We are a professional manufacturer of Tungsten CarbideTools, and can supply you with TNMG Series Turning Inserts:1. Super fine grain size material.

2. Excellent toughness and hardness.

3. Diversity of Chip-breaker for different workpiece materials.

4. Special grades for different workpiece materials.

5. Advance CVD multi-layer coating technology for extended tool life.

The Turning Inserts also can be made according to your own specification or against samples.

CVD Coated Grades are as follows:

| Grade | Description | Equivalent to ISO |

| JCP1015 | MT-CVD coated, the substrate with excellent wear resistance in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is suitable for finishing of steel. | P05~P15 |

| JCP2015 | MT-CVD coated, Cutting edge with good toughness in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is suitable for semi-finishing of steel. | P10~P25 |

| JCP3015 | MT-CVD coated, the substrate with excellent toughness and plastic deformation resistance in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is suitable for roughness of steel. | P20~P35 |

| JCM1015 | MT-CVD coated, the substrate with excellent wear resistance in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is optimal for finishing and semi-finishing of stainless steel. | M05~M15 |

| JCM2015 | MT-CVD coated, the substrate with special micro structure in combination with TiCN+Al2O3(thick)+TiN multi-layer coating, which is optimal for finishing and roughing of stainless steel. | M10~M25 |

| JCM3015 | MT-CVD coated, the substrate with excellent toughness in combination with TiCN+Al2O3(thin)+TiN multi-layer coating, which is optimal for semi-finishing and roughing of stainless steel. | M20~M35 |

| JCK1025 | MT-CVD coated, the super fine grain size substrate with excellent hardness in combination withAl2O3(extra thick) + TiCN(thick) coating, the smooth surface, which is suitable for turning and milling of grey cast iron at high speed | K05~K15 |

| JCK2025 | MT-CVD coated, the substrate with excellent hardness and stripping resistance in combination withAl2O3(thick) + TiCN(thick) coating, the smooth surface of the tools, which is suitable for turning and milling of cast iron at middle and high speed. | K10~K30 |

| JCK3025 | MT-VD coated, the substrate with excellent wear resistance and toughness in combination withAl2 |

Sample reference