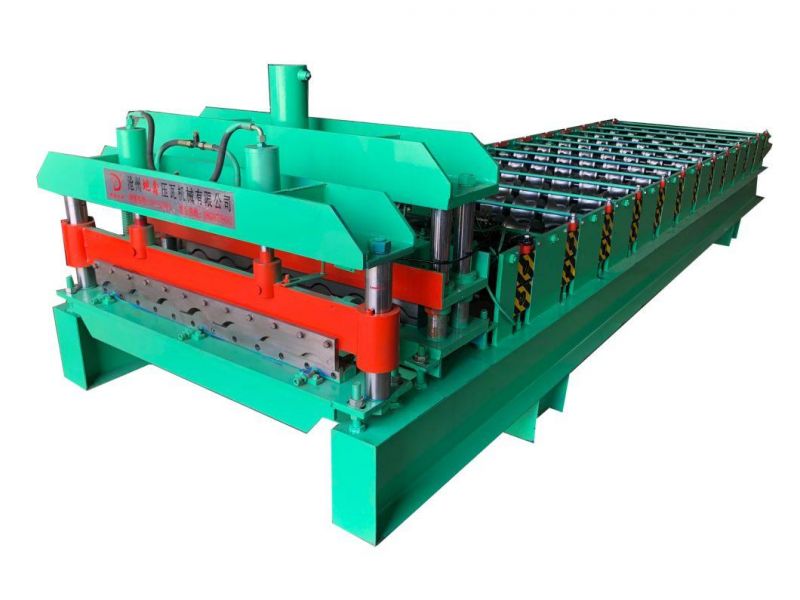

Aluminium Sheets Machine /Glazed Tile Color Roof Roll Forming Machine

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

Base Info

- Model NO.:DX1200

- Power Source:Hydraulic Pressure

- Feature:High Efficiency

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

- Customized:Customized

- Advantage:Use Widely

- Condition:New

- Name:Aluminum Coil Rolling Machine

- Feeding Material:Metal Steel Sheet,Color Steel,Galvanized Sheet

- Feeding Thickness:0.3-0.8 mm for Common Use

- Motor Power:8kw

- Shaft:75 mm, High Grade No. 45 Carbon Steel

- Roller:0.05mm Chromn and High Grade No. 45 Carbon Ste

- Control System:PLC Automatic Control System

- Cutting Blade:Cr12 Mould Steel with Quenched Treatment

- Forming Steps:13 Rows or as Your Requirement

- Type of Forming:Single Station with Chain Transmission

- Transport Package:Water-Proof Packaging, Covered with Plastic Film

- Specification:DX1080

- Trademark:DX

- Origin:Botou Hebei China

- HS Code:845522

- Production Capacity:20 Set Per Month

Description

Basic Info.

Model NO. DX1200 Power Source Hydraulic Pressure Feature High Efficiency Certification CCC, ISO9001, CE Warranty 12 Months Customized Customized Advantage Use Widely Condition New Name Aluminum Coil Rolling Machine Feeding Material Metal Steel Sheet/Color Steel/Galvanized Sheet Feeding Thickness 0.3-0.8 mm for Common Use Motor Power 8kw Shaft 75 mm, High Grade No. 45 Carbon Steel Roller 0.05mm Chromn and High Grade No. 45 Carbon Ste Control System PLC Automatic Control System Cutting Blade Cr12 Mould Steel with Quenched Treatment Forming Steps 13 Rows or as Your Requirement Type of Forming Single Station with Chain Transmission Transport Package Water-Proof Packaging, Covered with Plastic Film Specification DX1080 Trademark DX Origin Botou Hebei China HS Code 845522 Production Capacity 20 Set Per MonthProduct Description

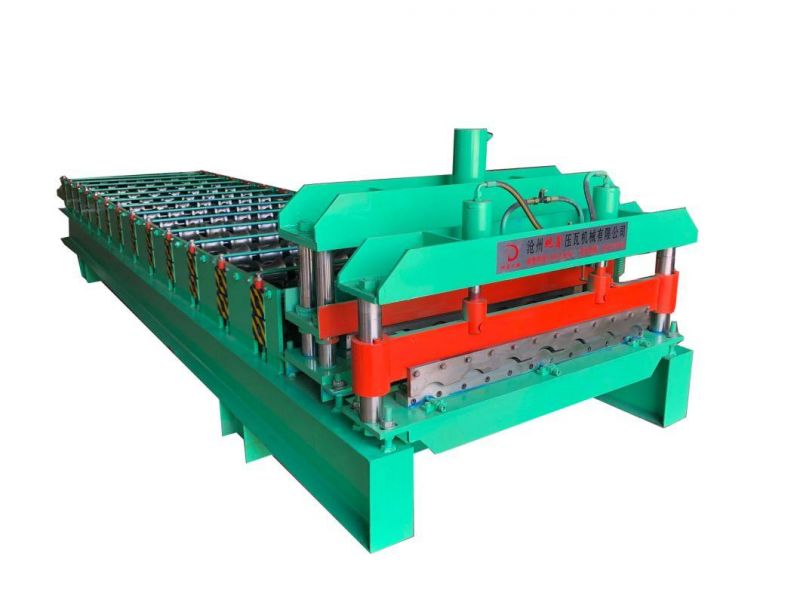

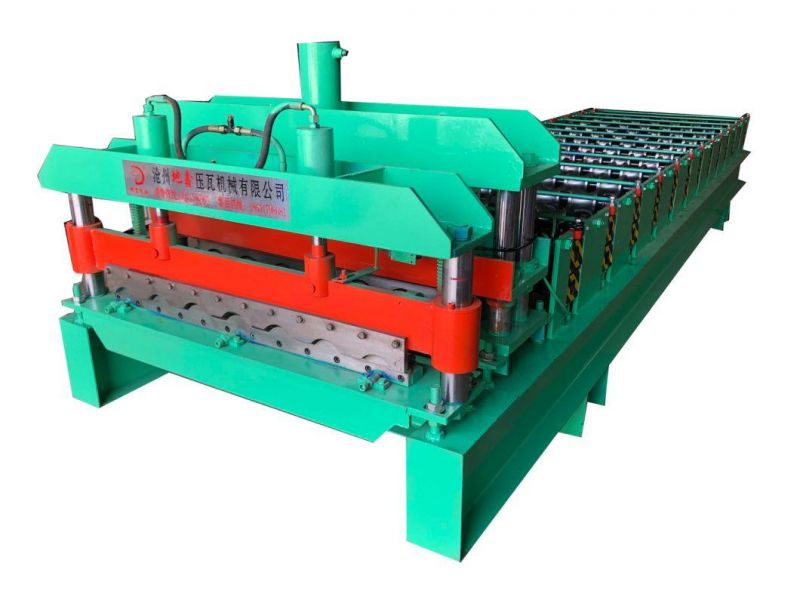

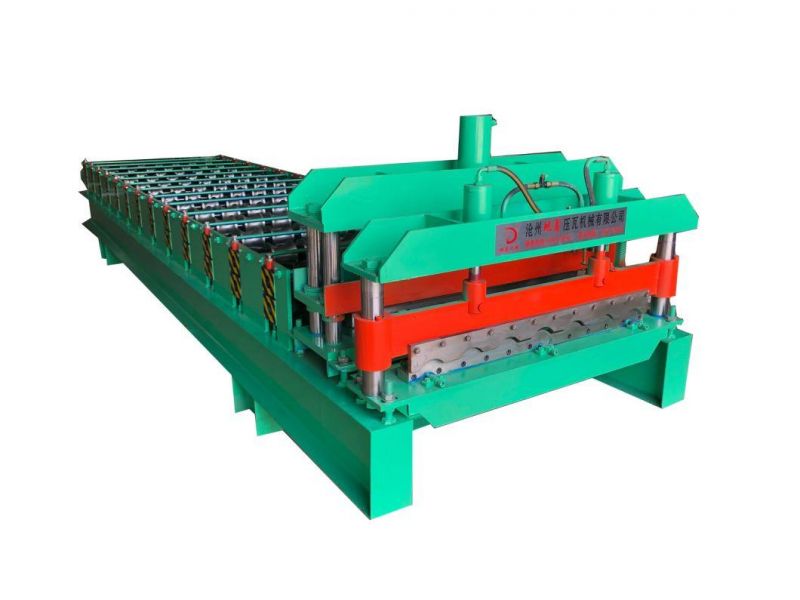

Aluminium Sheets Machine /Glazed Tile Color Roof Roll Forming MachineComponents for the Machine:

The roll forming machine includes manual uncoiler unit, infeed guide, fixed position driven forming stations, pressing die, cutting equipment, hydraulic station, PLC console and manual unload product run out table.

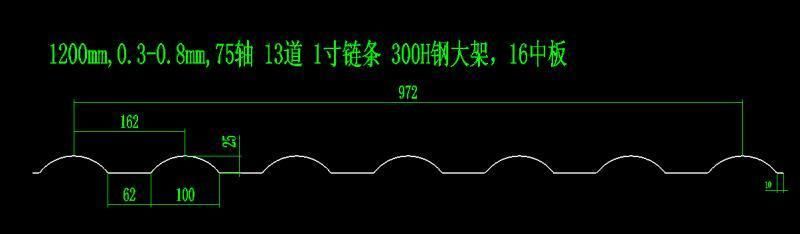

1.Panel drawing as customers request

2. Technique parameters

2. Technique parameters| Material specification | Aluminum, alu-zinc, galvanized and pre-painted galvanized steel. |

| Thickness | 0.3-0.7mm.(perfect is 0.4mm-0.6mm) |

| Main motor power | 5.5 kw. |

| Hydraulic station power | 4kw. |

| Feeding width | 1200mm. |

| Cover width | 972mm |

| Yield stress | 235Mpa (33KSI) ~ 345Mpa (50KSI). |

| Roll forming Speed | 15-18 m/min |

| Cutting Tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm<length≤10000mm). |

| Manual Uncoiler | Max. Capacity: 5000kgs. |

| Coil inner diameter | 508mm. |

| Voltage | 380V,3 Phase,50HZ,Or As per customer's request. |

| Numbers of stands | 17 stations |

| Type of cutting | Roll-formed and length-set profile cutting. |

| Roller Material | High grade S45C forged steel, coated with hard chrome. |

| Active Shaft Material | High grade S45C carbon wrought steel, diameter 76mm. |

| Electric Elements | PLC control console, touch screen and transducer, from Siemens, Germany. Other elements, from Schneider Electric, Germany. |

| Cutter Blades | Cr12MoV steel with quenched treatment, hardness HRC58~61, wear-resistance, good steel structure, long life. |

4.Company Introduce

Our enterprise, Cangzhou Dixin Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc. We can satisfy the different needs of different markets.

Warmly welcome to China to visit our factory and select the machines you need. Our address,Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China.

Our Serivice:

1. we can produce the special machine,send your drawing to us,we can design for you.

2. if you buy our products,we also can help you to purchase the material,like color roll,the price is lower than you buy by yourself.

3. we provide a one year warranty and lifelong technical support, we can send our technicians to you to give you on-site training.

The training period would be for no more than one week with the customer paying for the visa, return ticket, food, accommodations and a daily wage of US50.

4. engineers available to service machinery overseas.

5. if you come to visit our factory,we can book the room for you, car pick up to send.

Thanks for visiting our products, if you have interest, pls leave your message, or you can contact us, speical design is avaliable!