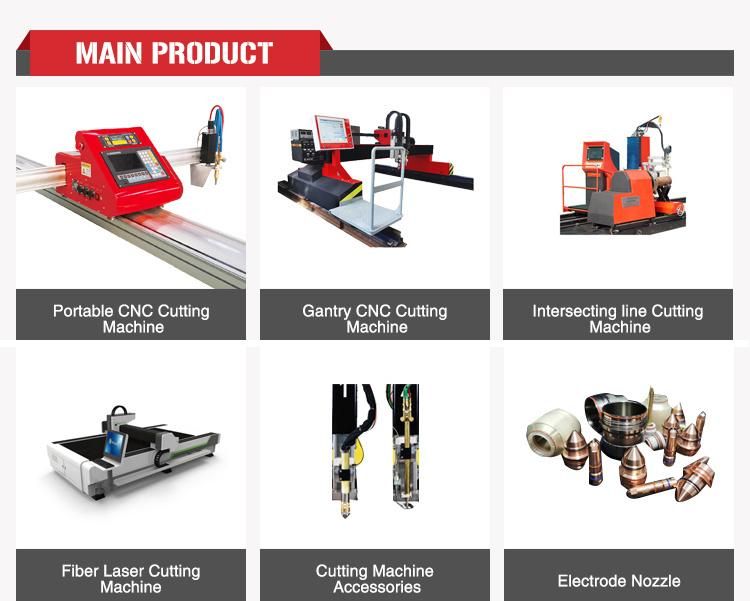

CNC Portable Plasma Cutting Machine 1500*3000mm with Plasma and Flame Cutting Mode

Meisar Changzhou Intelligent Technology Co., Ltd.- Warranty:1 Year

- Customized:Customized

- Layout:Horizontal

- Cutting Material:Copper, Carbon Steel, Iron, Aluminum, Metal Alloy, Stainless Steel

- Automatic Grade:Automatic

- Power Source:Electric

Base Info

- Model NO.:MS-1530HDX

- Cutting Mode:Plasma Cutting

- Motor:57 Stepper Motor

- Cutting Thickness:0-150mm

- Working Area:1500mm*3000mm

- Cutting Speed:0-8000mm,Min

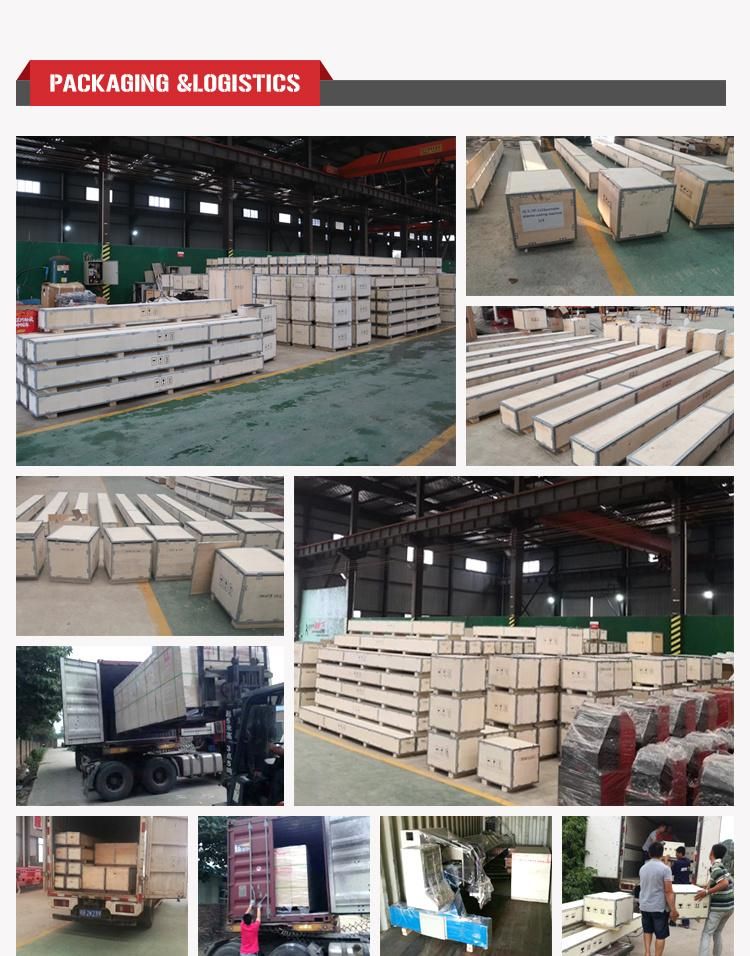

- Transport Package:Wooden Box

- Specification:300x300x3500mm 70kg+ 450x450x500mm 45kg

- Trademark:Meisar

- Origin:China

- HS Code:8456401000

- Production Capacity:1000sets,Month

Description

Technical Specification

Product Name

Portable Flame and Plasma CNC cutting machine

Model

MS-1530HDX

Control System

Fang Ling F2100B

Motor

57 Stepper Motor

Color

Red,Blue,Yellow.

Cutting Mode

Plasma Cutting+ Flame Cutting

Flame Cutting Gas

Oxygen with propane or acetylene

Plasma Torch Gas

Compressed air/N2/O2

Working Area

1500mm*3000mm or 2000mm*3000mm

Cutting thickness

0-150mm

Cutting speed

0-8000mm/min

Operation precision

0.2mm/m

Main Features:

1.Cross beam driving model, enables a more stable balance movement, avoid the head declining due to gravity

2.Reasonable cutting area: effective 1.5m*3.0m, suitable most common sheet 4ft*8ft

3.Light and smart, no fixed place occupation, sustain cutting on sheet directly

4.Simple structure, easy for packing, delivery, installation and disassemble

5.Overall processing alloy base, assure light and precise, no base shape deformation

6.Cross beam and rail both with linear guide, high accuracy good stability moving

7.With motor enable/disable button, ensure operator and machine safety and start position random select,save material save time.

QUALITY MANAGEMENT SYSTEM

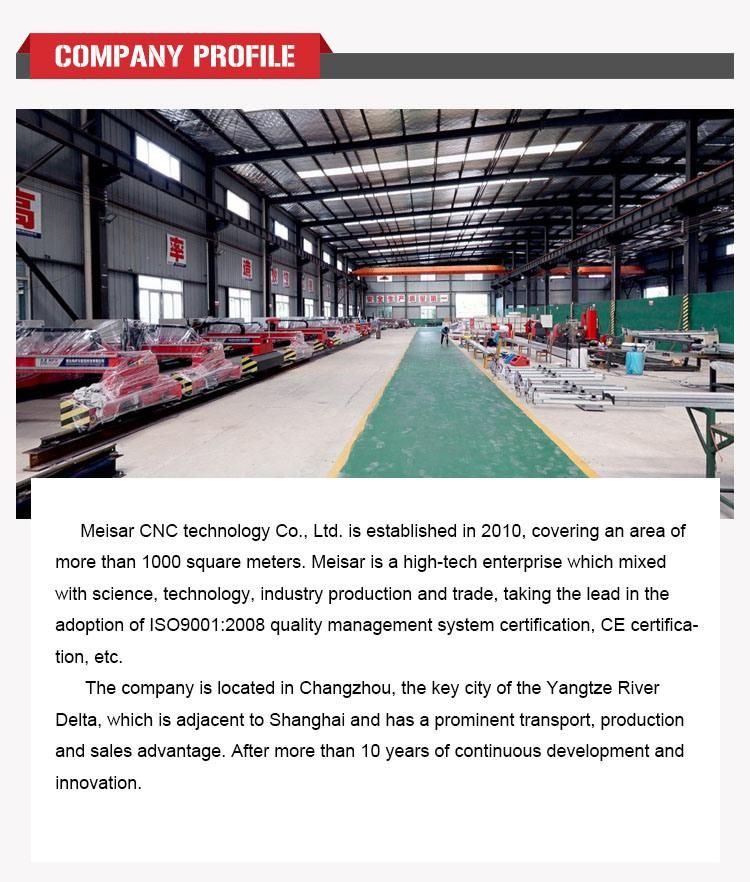

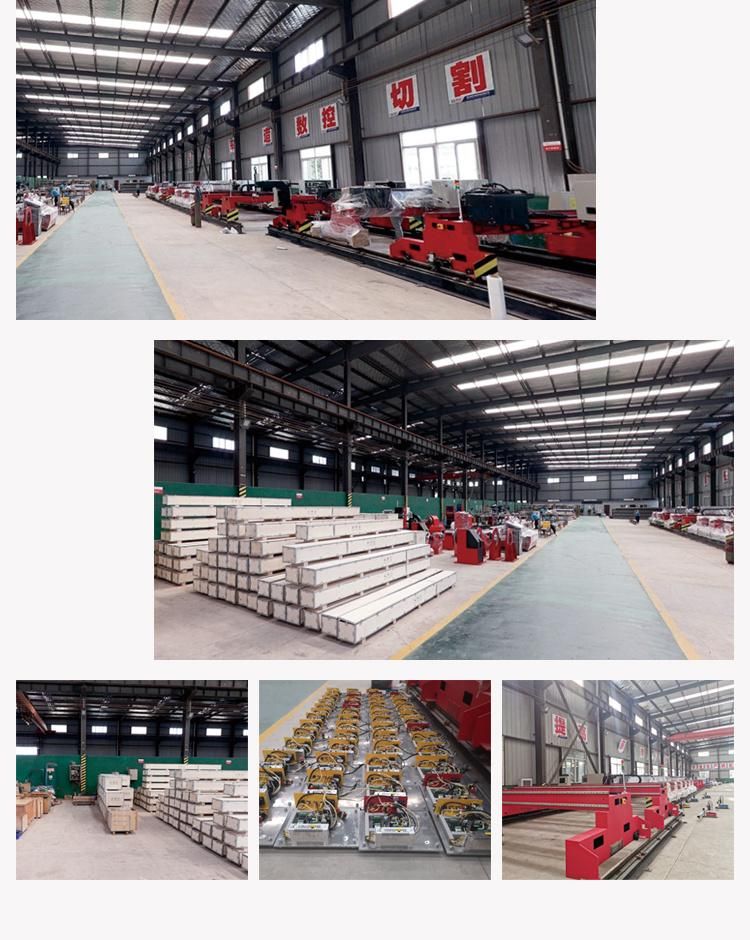

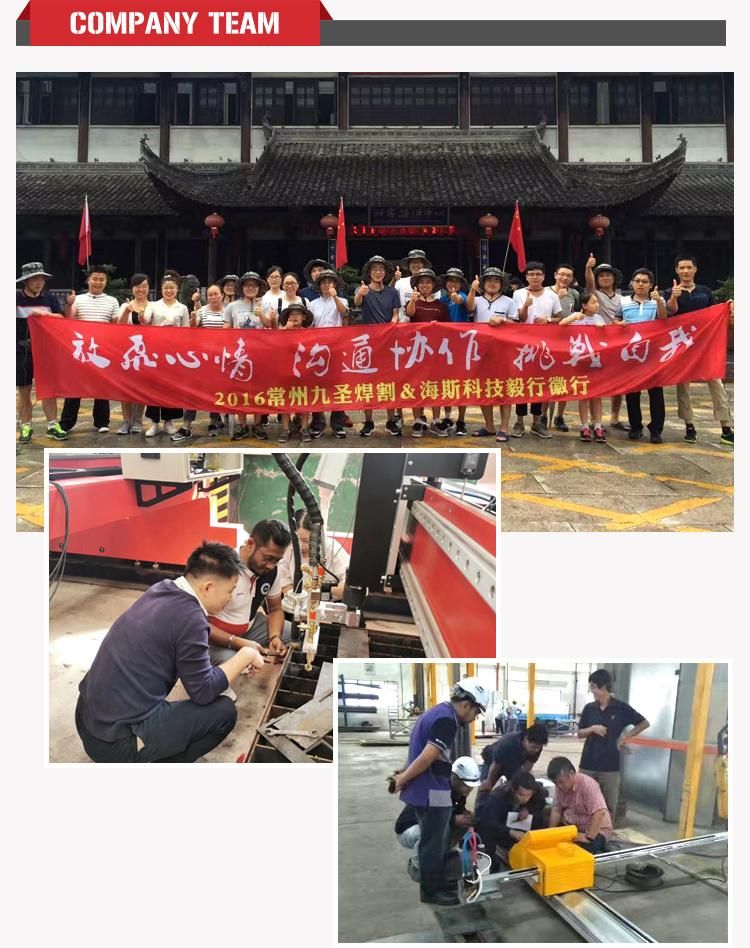

Heavth CNC is one of the biggest suppliers among cutting equipment in east China. Company mainly engage in CNC plasma cutting machine, CNC laser cutting machine, CNC Pipe/Tube cutting machine, etc. Heavth CNC has 14 years history, serving more than 80 countries and regions.

Heavth CNC has strict quality control system and quality management team. Strictly adhere to the general standards of the industry and company guidelines. Implement quality monitoring from every aspect of R&D, production and after-sales of laser equipment, to ensure that each device can meet customer's requirements.

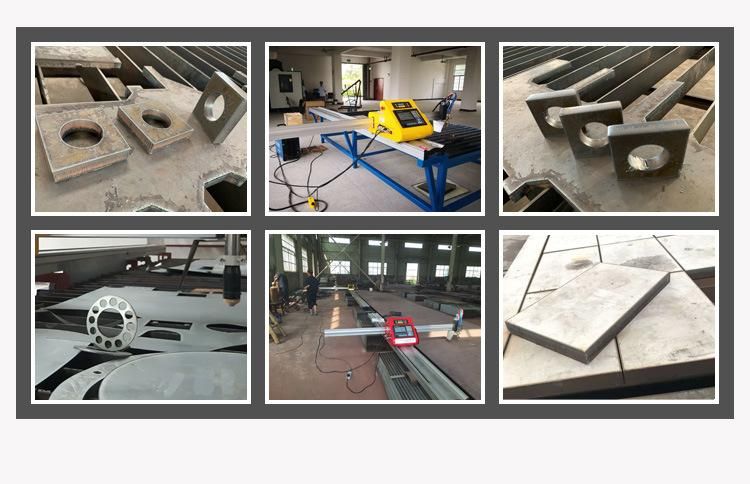

Incoming Inspection

For every part of the machine, Heavth CNC is strictly control the quality.

Not only require suppliers to provide quality inspection reports, but also strict quality monitoring will be carried out when the parts are in the factory.

Process Control

The assembly process of the machine will also affect the customer's feeling when using the machine, Therefore, in the process of machine assembly, Heavth CNC from the most basic machine bed to the final assembly of the whole machine is strictly followed by the quality management standard.