Aluminum Three Layer Metal Roofing Sheet Making Machine Best Price

Cangzhou Dixin Roll Forming Machine Co., Ltd.- Type:Rolling Machine

- Forging Forming Method:Mold Forging

- Power Source:Hydraulic Pressure

- Feature:Automation

- Certification:CCC, ISO9001, CE

- Warranty:12 Months

Base Info

- Model NO.:DX 1000-825-76-18

- Customized:Customized

- Advantage:Easy to Maintenance

- Condition:New

- Machine:Dx Corrugated Roof Rolling Machine

- Profile:1000-825-76-18

- Power:Electricity

- Voltage:380V,415V,240V

- Feeding:1000mm*0.25-0.08mm PPGI,Gi

- Production Line:16m*2.0m*2.0m

- Machine Size:6450m*1450m*1.5m

- Machine Weight:4.2 Tons

- Froming Speed:10-12m,Min

- Control System:Good Delta

- Transport Package:Waterproof Package and Naked Packing

- Specification:825 corrugated panel

- Trademark:DIXIN

- Origin:China, Hebei

- HS Code:845522

- Production Capacity:1 Set

Description

Basic Info.

Model NO. DX 1000-825-76-18 Customized Customized Advantage Easy to Maintenance Condition New Machine Dx Corrugated Roof Rolling Machine Profile 1000-825-76-18 Power Electricity Voltage 380V/415V/240V Feeding 1000mm*0.25-0.08mm PPGI/Gi Production Line 16m*2.0m*2.0m Machine Size 6450m*1450m*1.5m Machine Weight 4.2 Tons Froming Speed 10-12m/Min Control System Good Delta Transport Package Waterproof Package and Naked Packing Specification 825 corrugated panel Trademark DIXIN Origin China, Hebei HS Code 845522 Production Capacity 1 SetProduct Description

Aluminum three layer metal roofing sheet making machine best price

2.Technique parameters

(1) Processing material: aluminium /aluzinc/galvanized steel/colored steel coil

(2) Material thickness: 0.3-0.85mm,( max 0.85mm)

(3) Effective width: 825mm

(4) Feeding width: as panel drawing picture. Or up to you.

(5) Main motor power: 4 kw

(6) Pump power: 4 kw

(7) Shaft diameter: 75 mm

(8) Forming steps: 13 steps

(9) Roller material: 45# forged steel, with hard chrome plating

(10) Main frame: 300H steel

(11) Medium plate thickness: 16 mm

(12) Control systerm: PLC computer control with inverter

(13) Power supply: 380V, 3 Phase, 60Hz or as requirement

(14) 0veral size: 6450mm*1400mm*1500mm (a 20 foot container available)

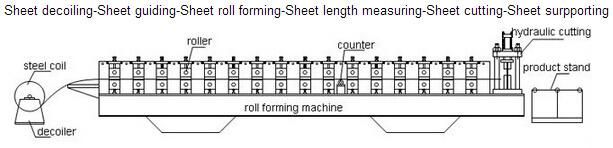

3. Work flow

1. Manual decoiler-Roll forming machine-PLC control-Hydraulic system -Post cut-Stacking

2. Whole line:

1)One set 5 ton manual uncoiler for free

2)Three sets collection tables for free

3) And other quick wear parts for free.

4.Loading

Pls,contact me for more details.

5.Payment term

TT 30% as the deposit on the order day,70% before delivery

6.Warranty

12 months, and lifelong technical support service

7. Installation

If you need, we will send one technician to your factory to install & testing the machine. You should assist the technician to get Visa and pay for flight tickets and local accommodation,

If u have any other question,please contact me any time.