Forging Industrial Valve CNC Machining Stainless Steel Hygienic /Sanitary Ball Valve Parts

Ningbo Hento Metal Products Co., Ltd.- After-sales Service:Maintenance

- Warranty:1 Year

- Condition:New

- Certification:CE, RoHS, GS, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

Base Info

- Material:Stainless Steel

- Application:Metal Cutting Machine, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

- Service Support Country:U.S,Canada, South America ,MID-East ,etc

- Transport Package:Carton + Pallet

- Specification:Sizes 1,2 "-4"

- Trademark:Hento

- Origin:China

- HS Code:84779000

- Production Capacity:50000PCS ,Year

Description

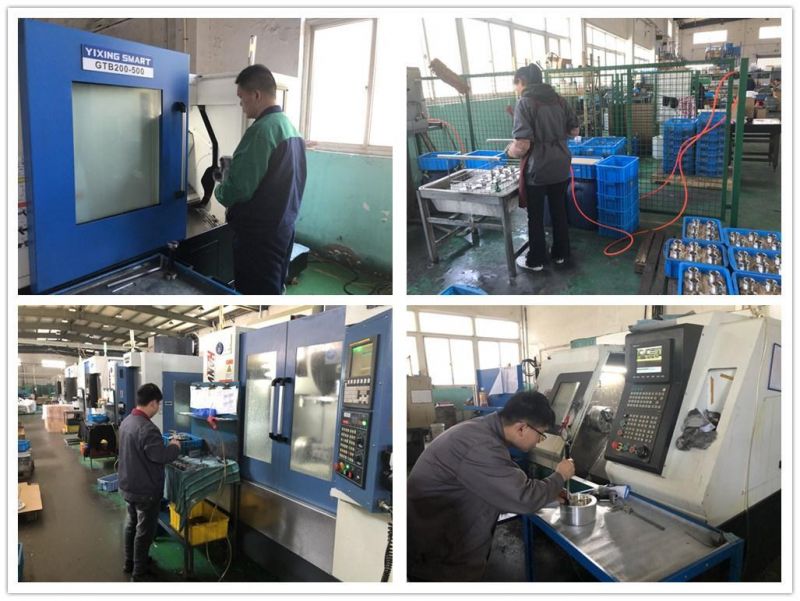

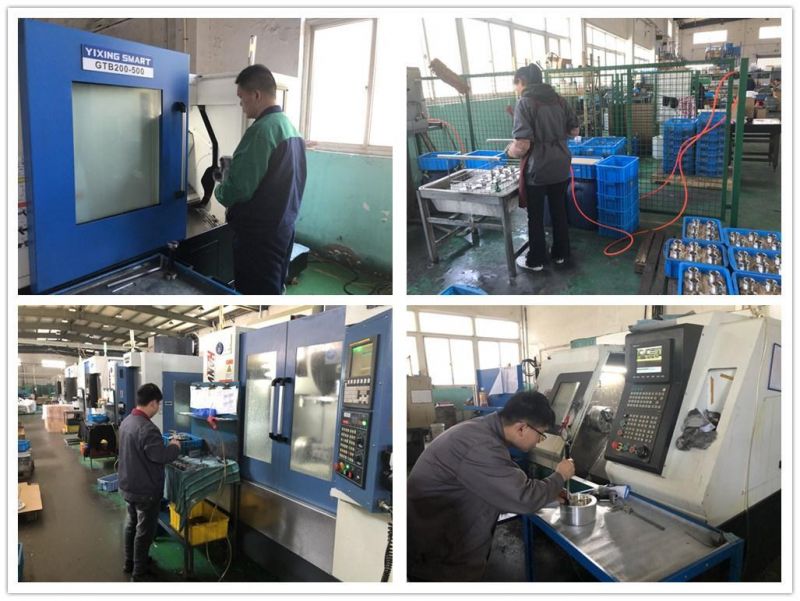

Our AdvantagesReliable Quality Competitive Price High precision, high quality, tight tolerance On-Time Delivery Continuous Improvement Defect-Free Products Customer Satisfaction Excellent After-Sales Service No. Name Model Q'TY Equipment Manufacturer Size Spec./ Range of Work Machine Accuracy 1 CNC machining center 850(950*520) 10 HANVOS ¢500*800(D*L) 0.002 2 CNC machining center V52(750*420) 2 HANVOS ¢400*600(D*L) 0.002 3 CNC machining center V64(1300*600) 1 HANVOS ¢600*1000(D*L) 0.002 4 CNC lathe SX-6136P/450 9 ShengXiang ¢150*400(D*L) 0.005 5 CNC lathe SX-6150/450 2 ShengXiang ¢150*400(D*L) 0.01 6 CNC lathe CJK0640B 2 YaoFa 200*500(D*L) 0.01 7 CNC lathe D370 1 David Beijing 300*700(D*L) 0.005 8 Benchtop tapping machine SWJ-6 3 West Lake ¢1-¢25 9 Bench boring machine Z512-2 2 West Lake ¢1-¢20 10 Laser marking machine JG300/200 1 HongGuang 300*200(L*L)

About Hento

Ningbo Hento Metal Products Co., LTD, located in Ningbo City, Zhejiang Province, China, is a professional manufacturer integrated with production and research & development.

Products are widely used in industries such as petroleum, electric power, automobile, food, chemical engineering, railway, mining, steel, shipbuilding and machinery etc.;

Our main products are silica sol precision casting, forging and precision machining of stainless steel 304, 304 L, 304, 316 L and A182 - F316L; other related materials: zinc alloy, alloy steel, brass, lead-free copper, ductile iron, grey iron, etc.; related technology: precision casting, forging, zinc-aluminum die-casting, punching press, welding, structural section and bar processing etc.

The tolerance of finished products can be controlled within 0.01 mm (0.0004 in); and the roughness can be controlled at Ra0.4

90% of Products are exported to countries and regions such as the United States and the European Union

Manufacturing equipment: 4-axis CNC machining center; CNC lathe; and related auxiliary equipment;

Test equipment: advanced testing methods and equipment such as tensile strength tester, hardness tester, projector and CMM are adopted to ensure production process

Surface treatment: powder spraying, painting, electroplating, electrophoresis and polishing, etc.

Working Time

About Hento

Ningbo Hento Metal Products Co., LTD, located in Ningbo City, Zhejiang Province, China, is a professional manufacturer integrated with production and research & development.

Products are widely used in industries such as petroleum, electric power, automobile, food, chemical engineering, railway, mining, steel, shipbuilding and machinery etc.;

Our main products are silica sol precision casting, forging and precision machining of stainless steel 304, 304 L, 304, 316 L and A182 - F316L; other related materials: zinc alloy, alloy steel, brass, lead-free copper, ductile iron, grey iron, etc.; related technology: precision casting, forging, zinc-aluminum die-casting, punching press, welding, structural section and bar processing etc.

The tolerance of finished products can be controlled within 0.01 mm (0.0004 in); and the roughness can be controlled at Ra0.4

90% of Products are exported to countries and regions such as the United States and the European Union

Manufacturing equipment: 4-axis CNC machining center; CNC lathe; and related auxiliary equipment;

Test equipment: advanced testing methods and equipment such as tensile strength tester, hardness tester, projector and CMM are adopted to ensure production process

Surface treatment: powder spraying, painting, electroplating, electrophoresis and polishing, etc.

Working Time