Customized Injection Mold for Auto Parts of Spoiler with PC/ABS/PA6+GF Chinese Manufacturer

Kunshan Wangdaxin Precision Mould Technology Co., Ltd.- Condition:New

- Certification:CE, ISO9001

- Standard:DIN, ASTM, GOST, GB, JIS, ANSI, BS

- Customized:Customized

- Material:Metal

- Application:Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery

Base Info

- Model NO.:25

- Mold Design:According to Customer′s Drawing and Sample

- Transport Package:Ocean Shipping

- Specification:50X50X50

- Trademark:WDX

- Production Capacity:10

Description

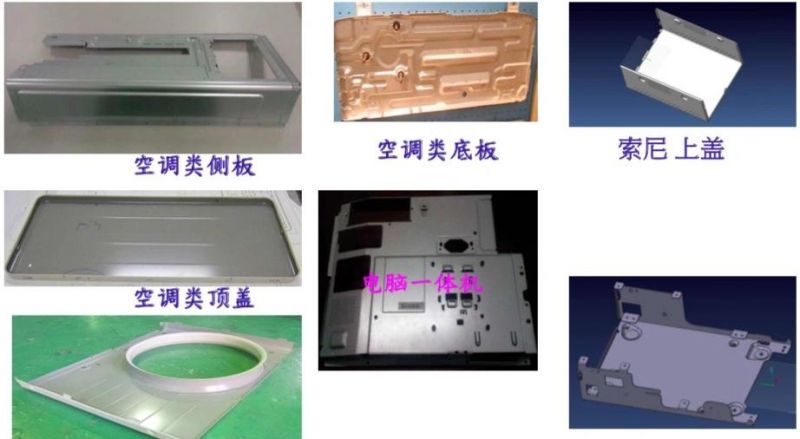

Cases of household appliances:

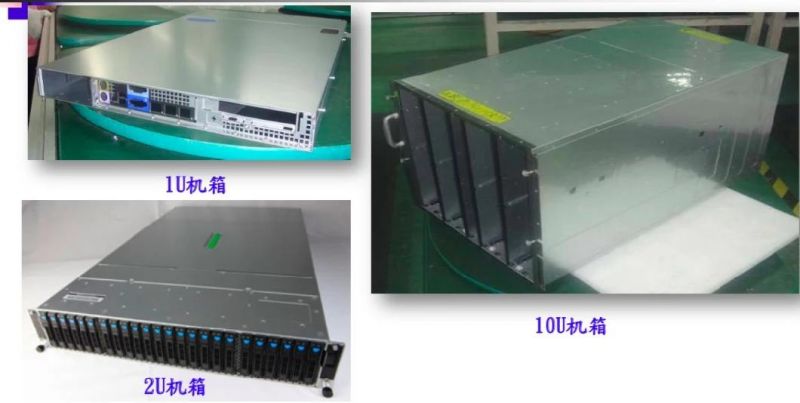

Cases of household appliances: Development of server mould:

Development of server mould:

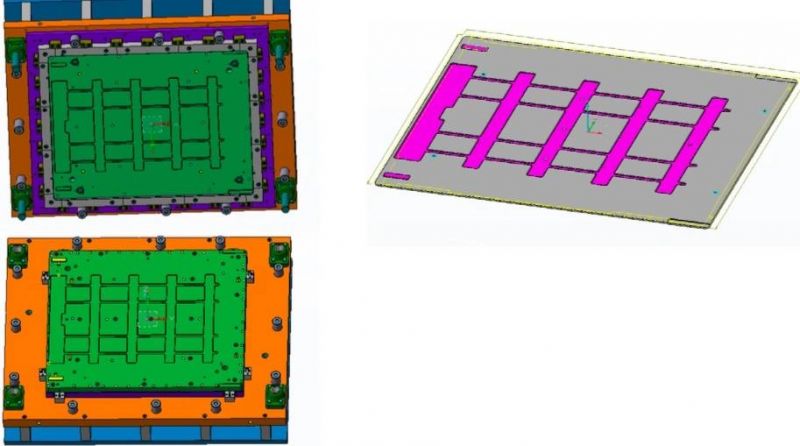

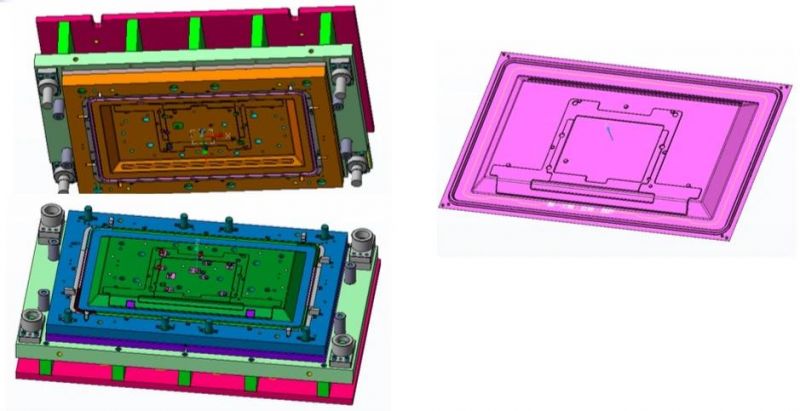

Mold development case:

Precision Metal Cutting Punching Forming Mould Other Information:

Precision Metal Cutting Punching Forming Mould Other Information:1. Mold Main project:

Precision metal mold manufacturing, metal stamping parts (CNC processing)

2. Equipment description:

All the processing equipment in the factory is imported from well-known domestic and foreign brands, lathes, grinders, milling machines, punches, wire cutting machines, CNC series

3. Mold type:

Metal mold, stamping mold, continuous mold, deep drawing mold, multi-station progressive mold

4. Mould material: A3.45 CR12.CR12MOV.D2.SKD-11.DC53.2510.3697.XW40.ASP-60

5. Mold shape:

The length, width and height of the mold can be determined according to the size of the drawings or samples provided by the customer.

6. Mold Use life:

During the use of the mold, combined with the manufacture of mold materials, stamping materials, and stamping times, the mold life is one million times.

7. Mould Process:

Customers provide the product drawings or samples-process review and order confirmation-mold design-mold steel processing-machine process-heat treatment-grinding processing-wire cutting processing-mold assembly-trial mold- Product Inspection-Customer confirm the sample--Mold Inspection--Mold Delivery