Beveling Milling Machine for LNG Tank and Heavy Duty Metal

Shanghai Taole Machine Co., Ltd.- After-sales Service:Online or Remote Support

- Warranty:1 Year Guarantee

- Type:Plate Beveling Machine

- Style:Auto Walking

- Layout:Vertical

- Automatic Grade:Semi-Automatic

Base Info

- Model NO.:GMMA-100L

- Power Source:Electric

- Certification:CE, ISO

- Bevel Angel:0-90 Degree

- Plate Thickness:8-100mm

- Milling Head:Dia 100mm

- Single Bevel Width:0-30mm

- Max Bevel Width:Upto 100mm

- Transport Package:Wooden Case

- Specification:1200J*1200

- Trademark:TAOLE

- Origin:Shanghai, China

- HS Code:846090

- Production Capacity:600 Sets Per Year

Description

Basic Info.

Model NO. GMMA-100L Power Source Electric Certification CE, ISO Bevel Angel 0-90 Degree Plate Thickness 8-100mm Milling Head Dia 100mm Single Bevel Width 0-30mm Max Bevel Width Upto 100mm Transport Package Wooden Case Specification 1200J*1200 Trademark TAOLE Origin Shanghai, China HS Code 846090 Production Capacity 600 Sets Per YearProduct Description

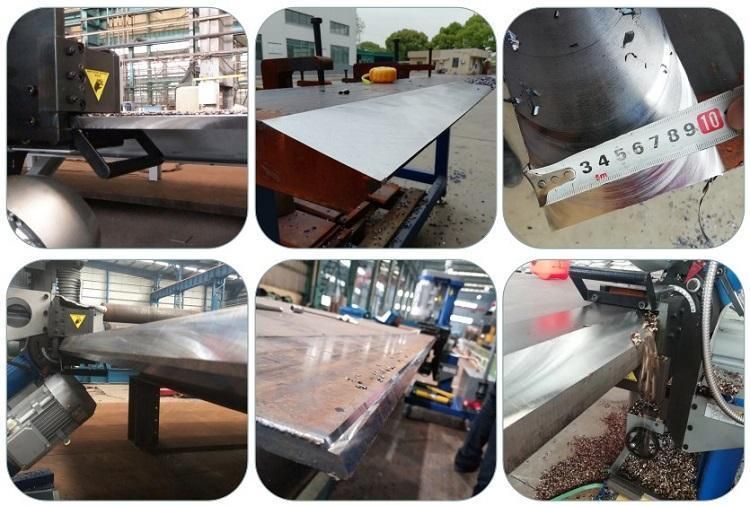

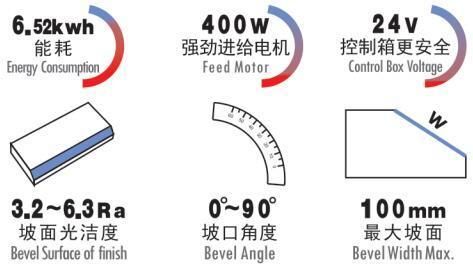

GMM-100L Beveling Milling Machine for LNG TANK and Heavy Duty MetalGMM-100L Beveling Milling Machine for LNG TANK and Heavy Duty Metal mainly to do bevel cutting or clad removal / clad stripping on steel plates material like mild steel, stainless steel, aluminum steel,alloy titanium,hardox,duplex etc. GMMA-100L heavy duty plate beveling machine for plate thickness from 8 to 100mm, bevel angel from 0 to 90 degree adjutable. GMMA-100L can make 30mm per cut. 3-4 cuts to achieve bevel width 100mm which is high efficiency and helps a lot for saving time and cost.

Specifications for GMM-100L Beveling Milling Machine for LNG TANK and Heavy Duty Metal

| Models | GMMA-100L |

| Power Suppy | AC 380V 50HZ |

| Total Power | 6520W |

| Spindle Speed | 500-1050mm/min |

| Feed Speed | 0~1500mm/min |

| Clamp Thickness | 8~100mm |

| Clamp Width | >100mm |

| Clamp Length | >300mm |

| Bevel Angel | 0~90 degree |

| Singel Bevel width | 15-30mm |

| Bevel Width | 0-100mm |

| Cutter Diameter | Dia 100mm |

| Inserts QTY | 7 pcs/9pcs |

| Worktable Height | 810-870mm |

| Suggest Table Height | 830mm |

| Worktable Size | 1200*1200mm |

| Clamping Way | Auto Clamping |

| Wheel Size | 4 Inch Heavy duty |

| Machine Height Adjust | Handwheel |

| Machine N.Weight | 420 kgs |

| Machine G Weight | 480 kgs |

| Wooden Case Size | 950*1180*1430mm |

Futures for GMM-100L Beveling Milling Machine for LNG TANK and Heavy Duty Metal

1) Automatic walking type beveling machine will walk along with plate edge for bevel cutting

2) Beveling machines with universal wheels for easy moving and storage (Heavy duty wheels for heavy duty plates)

3) Cold cutting to aovid any oxide layer by using milling head and inserts for higher performance on surface Ra 3.2-6.3 . It can do welding directly after bevel cutting. Milling inserts are market standard.

4) Wide working range for plate clamping thickness and bevel angels adjustable.

5) Unique design with reducer setting behand more safe.

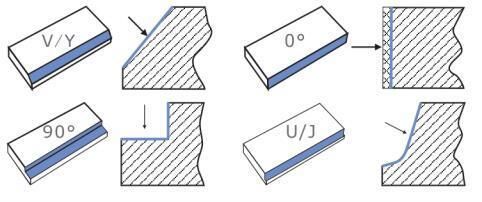

6) Available for multi bevel joint type and easy operation.

7) High efficiency beveling speed reach 0.4~1.2 meters per min.

8) Automatic Clamping system and hand wheel setting for slight adjustment.

Application for GMM-100L Beveling Milling Machine for LNG TANK and Heavy Duty Metal

1. GMMA-100L specially for heavy duty plates

2. Applicatd industry like steel construction, shipbuilding,pressure vessel,welding manufacturing

RFQ

Q1: Are you factory?

A1: Yes. We are the direct manufacture for beveling machine with brand of "TAOLE" and export with company name of "SHANGHAI TAOLE MACHINE CO.,LTD"

Q2: How long do you need for shipment?

A2; Standard models of beveling machine are stock avaiblable which could be test and pack ready in 3-5 days. Customized solutions normally need 30-45 days fresh made. CNC edge milling machine request 3-4 months.

Inquiry Guide for plate beveling machine

Before exact price offer. Can you pls advise below points to choose suitable models for metal sheet beveling?

- Are you user or reseller for this beveling machine?

- What is your plate material? ( Like Carbon steel, stainless steel or alloy steel etc)

- What is your plate sizes? (Maximum and Minimum will be OK)

- Do you request high precisions on the bevel surface?

- What kind of bevel joint do you need to process? Mostly like V/Y, K/X, U/J,L type, 0 degree clad removal.

- How about bevel sizes ? (Better if could share the drrawing and sizes)