High Precision Industrial Parts Aluminum Die Casting

Xiamen Stick Industry Co., Ltd.- Condition:New

- Certification:CE, RoHS, ISO9001

- Standard:DIN, ASTM, JIS

- Customized:Customized

- Material:Alloy

- Application:Metal Recycling Machine, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal Casting Machinery

Base Info

- Model NO.:STK-ADC-192

- Machine Size:80-280 Tons

- Brand Name:Customized or Stk

- Product Material:Zinc Alloy, Aluminum Alloy, Stainless Steel, Steel

- Served Industry:Availabel for Home Door or Other Building Room Doo

- Lead Time:2-4 Weeks

- Packaging:Carton Box, Wooden Crate, as Your Requirement

- Door Thickness Fits:Customized

- OEM/ODM:Both Available

- Weight Available:10GS to 10kgs

- Quality Control:Professional Inspection

- Tolerance:Machining:+,-0.05mm

- Process:Casting. Deburring .Drilling .Threading

- Free Sample:Availble

- Market:Global

- Size:Customer′s 3D Drawing

- Transport Package:Bubble Bag+Export Carton

- Specification:As per required

- Trademark:STK or customized

- Origin:Xiamen, Fujian, China

- HS Code:76169090

- Production Capacity:500, 000 PCS,Month

Description

Surface Finish1. Shot Blasting 2. Vibratory Finishing 3. Light-bead Blasting 4. Thermal De-Burr 5. Anodizing 6. Powder Coating 7. Sand Blasting 8. E-Coating 9. Passivation 10. T-Coating OEM Service Provided Yes Production Capacity Automated equipment handles high volume casting jobs of up to 100,000 pieces per week

Aluminum Die Casting Solution:

Aluminum die casting alloys are lightweight while possessing high dimensional stability for complex shapes and thin walls. Aluminum has good corrosion resistance and mechanical properties, high thermal and electrical conductivity, as well as strength at high temperatures.

Production Capability:

1. Automated equipment can handle high volume casting jobs of up to 100, 000 pieces per week

2. Manual machines for low volume jobs of as little as 500 pieces per year

3. Can cast from 0.02 to10kgs

4. Single to Multiple Cavities

5. Most aluminum die casting alloys are offered such as ADC10, ADC12, A380, 383, B390 (YL117), YL112, YL104

6.10 die casting and gravity casting lines, each with an individual aluminum furnace - this allows us to cast multiple alloys each day

7.7 Sets of cold chamber die casting machines range from 125 tons to 800 Tons, 3 sets of gravity machines

Molds Created On-Site:

In addition to die-casting, Stick Industry is a full-service mold manufacturing facility offering in-house tooling design and production. Where most die-casting facilities only offer mold repair, Stick Industry can create a custom mold on-site, and then simply transfer that mold to the die-casting area.

Stick Industry is capable to obtain the relevant data to produce molds and product samples according to the latest3-D solid model and a simple sketch or a sample part. Plus, we use the most modern multi-axis CNC machine tools for optimum precision

Xiamen Stick Industry Co., Ltd offers the cost-saving advantage for the manufacture of customers' Aluminum die casting parts requirements .

STICK INDUSTRY, a multi-plant die caster and injection molder. We have full-service capabilities making us a one-stop die casting and molding source.

We will serve as a single source of responsibility for everything from initial design assistance to precision machining, metal finishing and final assembly.

We are committed to producing quality products, providing total customer satisfaction and delivering Chinese Made value, competitively and quickly.

We look forward to servicing your casting needs.

Aluminum Die Casting Workshop

We have a comprehensive production line, and equipped with advanced facilities. The Factory is consist of the below departments, as Casting Dept, CNC Machining Dept, Polishing Dept and Surface treatment Dept etc.

At the same time, our quality inspector will daily check the production staus, include the 5S sanitary environment and guarantee the good quality, and get rid of the defects

Aluminum Die Casting

Equiped with 7 cold chamber aluminum die casting machines and 3 gravity machine, can handle high volume casting jobs of up to 100,000 pieces per week.

Equipment List

Secondary Machining Process

Drilling, Milling, Tapping, CNC Machining , Deburring ect

Surface Treatment:

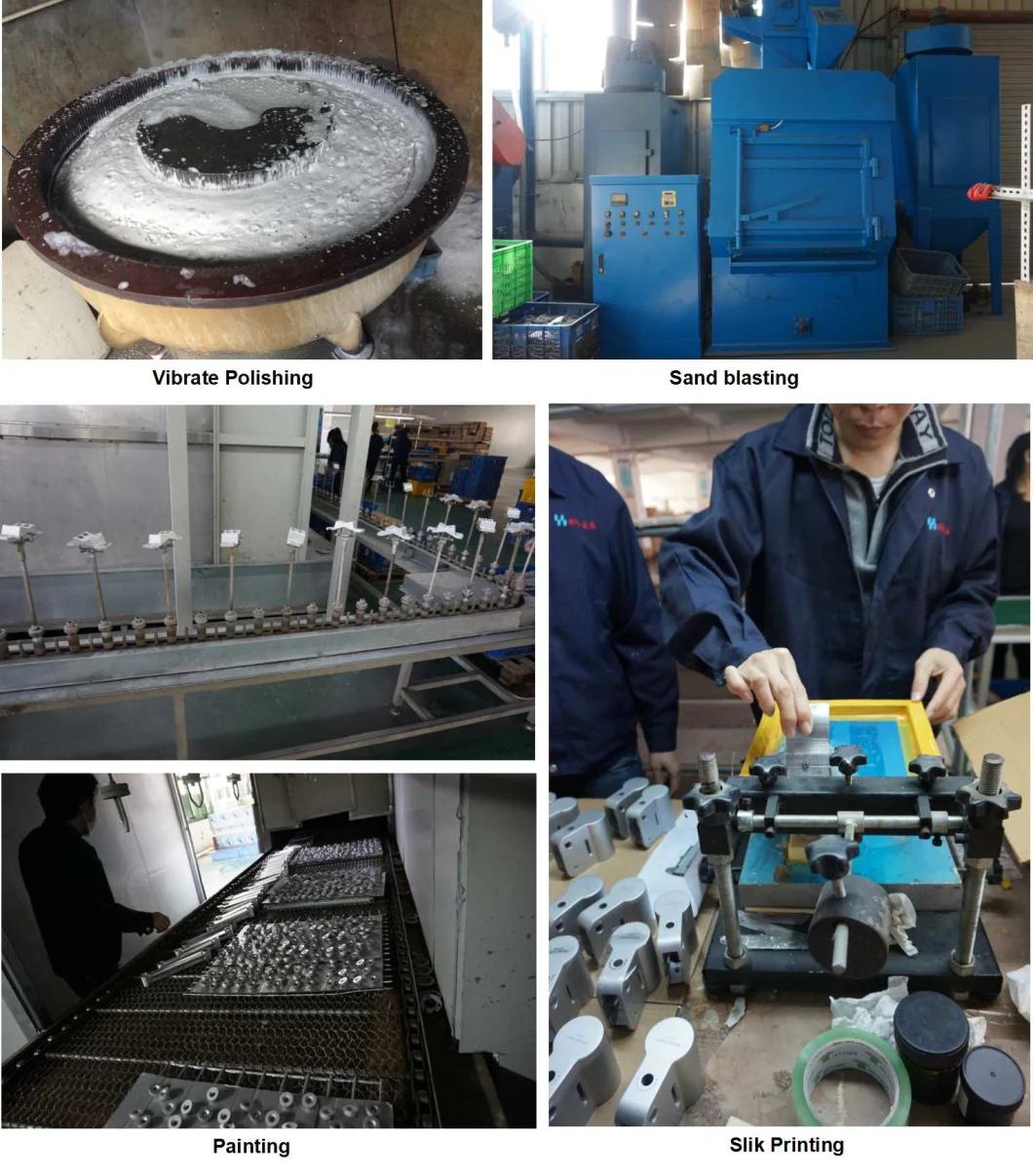

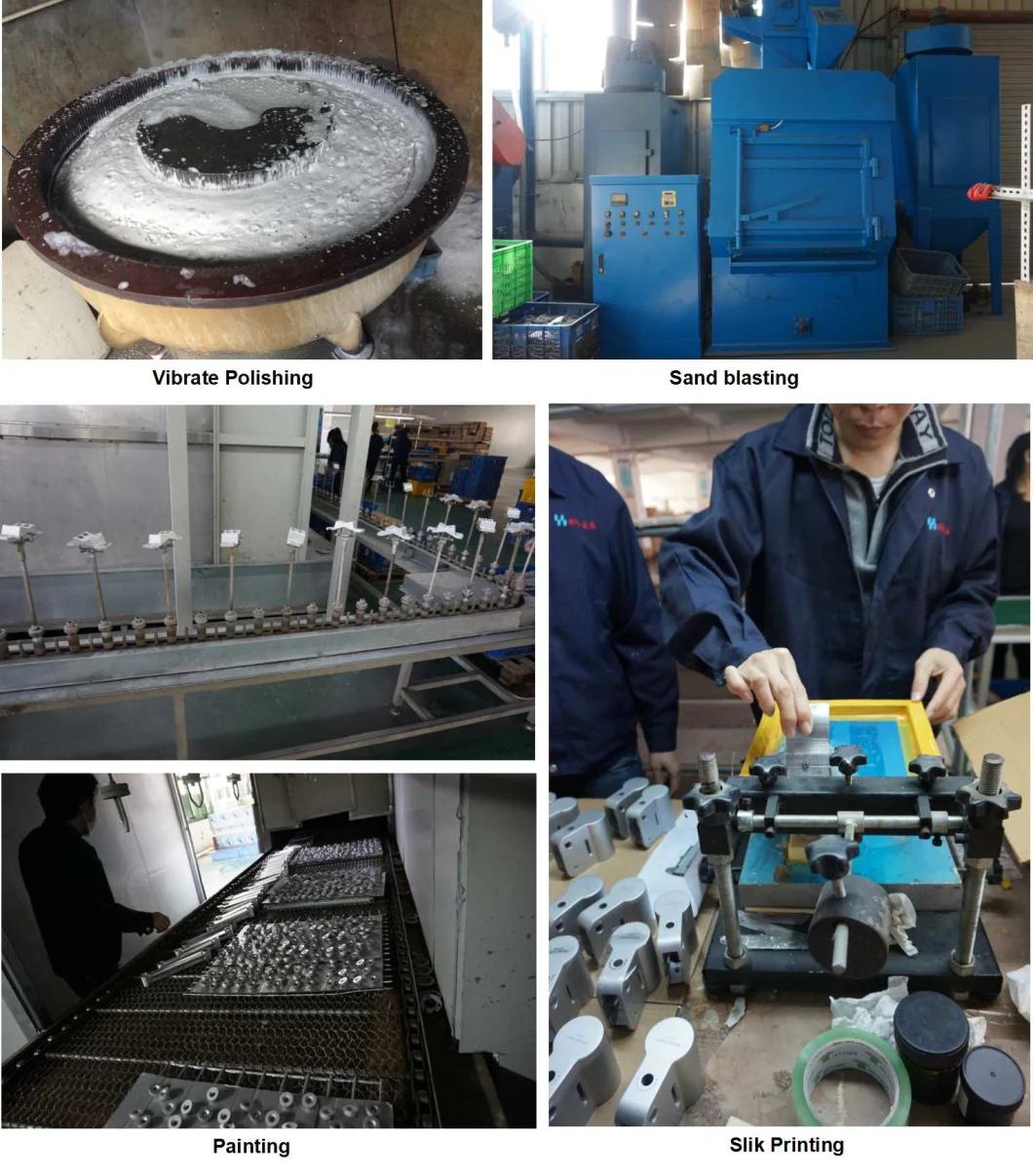

Surface treatment department can make various surface treatment to meet client's request. Such as Vibrate Polishing , Sandblast , Painting , Silk printing , Powder Coating etc .

We own a full service line for aluminum die casting, from raw castings, secondary machining to polish and painting, we all finish in our own factory. Which makes us easier to control the quality and meet the urgent request of some customers.

Inspection & Warehousing

Certificate:

Aluminum Die Casting Solution:

Aluminum die casting alloys are lightweight while possessing high dimensional stability for complex shapes and thin walls. Aluminum has good corrosion resistance and mechanical properties, high thermal and electrical conductivity, as well as strength at high temperatures.

Production Capability:

1. Automated equipment can handle high volume casting jobs of up to 100, 000 pieces per week

2. Manual machines for low volume jobs of as little as 500 pieces per year

3. Can cast from 0.02 to10kgs

4. Single to Multiple Cavities

5. Most aluminum die casting alloys are offered such as ADC10, ADC12, A380, 383, B390 (YL117), YL112, YL104

6.10 die casting and gravity casting lines, each with an individual aluminum furnace - this allows us to cast multiple alloys each day

7.7 Sets of cold chamber die casting machines range from 125 tons to 800 Tons, 3 sets of gravity machines

Molds Created On-Site:

In addition to die-casting, Stick Industry is a full-service mold manufacturing facility offering in-house tooling design and production. Where most die-casting facilities only offer mold repair, Stick Industry can create a custom mold on-site, and then simply transfer that mold to the die-casting area.

Stick Industry is capable to obtain the relevant data to produce molds and product samples according to the latest3-D solid model and a simple sketch or a sample part. Plus, we use the most modern multi-axis CNC machine tools for optimum precision

About us more detail:

Xiamen Stick Industry Co., Ltd is a professional OEM/ODM Manufacturer and Exporter of die castings, zinc die casting parts, zamak die castings, Aluminum Die Casting parts, die casting mold, gravity casting, gravity casting partsXiamen Stick Industry Co., Ltd offers the cost-saving advantage for the manufacture of customers' Aluminum die casting parts requirements .

STICK INDUSTRY, a multi-plant die caster and injection molder. We have full-service capabilities making us a one-stop die casting and molding source.

We will serve as a single source of responsibility for everything from initial design assistance to precision machining, metal finishing and final assembly.

We are committed to producing quality products, providing total customer satisfaction and delivering Chinese Made value, competitively and quickly.

We look forward to servicing your casting needs.

Aluminum Die Casting Workshop

We have a comprehensive production line, and equipped with advanced facilities. The Factory is consist of the below departments, as Casting Dept, CNC Machining Dept, Polishing Dept and Surface treatment Dept etc.

At the same time, our quality inspector will daily check the production staus, include the 5S sanitary environment and guarantee the good quality, and get rid of the defects

Aluminum Die Casting

Equiped with 7 cold chamber aluminum die casting machines and 3 gravity machine, can handle high volume casting jobs of up to 100,000 pieces per week.

Equipment List

| Machine | Capacity | Qty |

| Cold Chamber Die Casting Machine | 125 Tons | 2 Sets |

| Cold Chamber Die Casting Machine | 250 Tons | 2 Sets |

| Cold Chamber Die Casting Machine | 350 Tons | 1 Set |

| Cold Chamber Die Casting Machine | 650 Tons | 1 set |

| Cold Chamber Die Casting Machine | 800 Tons | 1 Set |

| Gravity Die Casting Machine | 750mm x 630mm | 3 Sets |

| CNC Lathe Machine | 10 Sets | |

| Milling Machine | 8 Sets | |

| Drilling Machine | 20 Sets | |

| Tapping Machine | 10 Sets | |

| Vibrate Polish Machine | 3 Sets | |

| Sand Blasting Machine | 2 Sets | |

| Painting Line | 2 Lines |

Secondary Machining Process

Drilling, Milling, Tapping, CNC Machining , Deburring ect

Surface Treatment:

Surface treatment department can make various surface treatment to meet client's request. Such as Vibrate Polishing , Sandblast , Painting , Silk printing , Powder Coating etc .

We own a full service line for aluminum die casting, from raw castings, secondary machining to polish and painting, we all finish in our own factory. Which makes us easier to control the quality and meet the urgent request of some customers.

Inspection & Warehousing

Certificate: