Grinding and Polishing of Plates Dry Machining Automated Deburring Machine

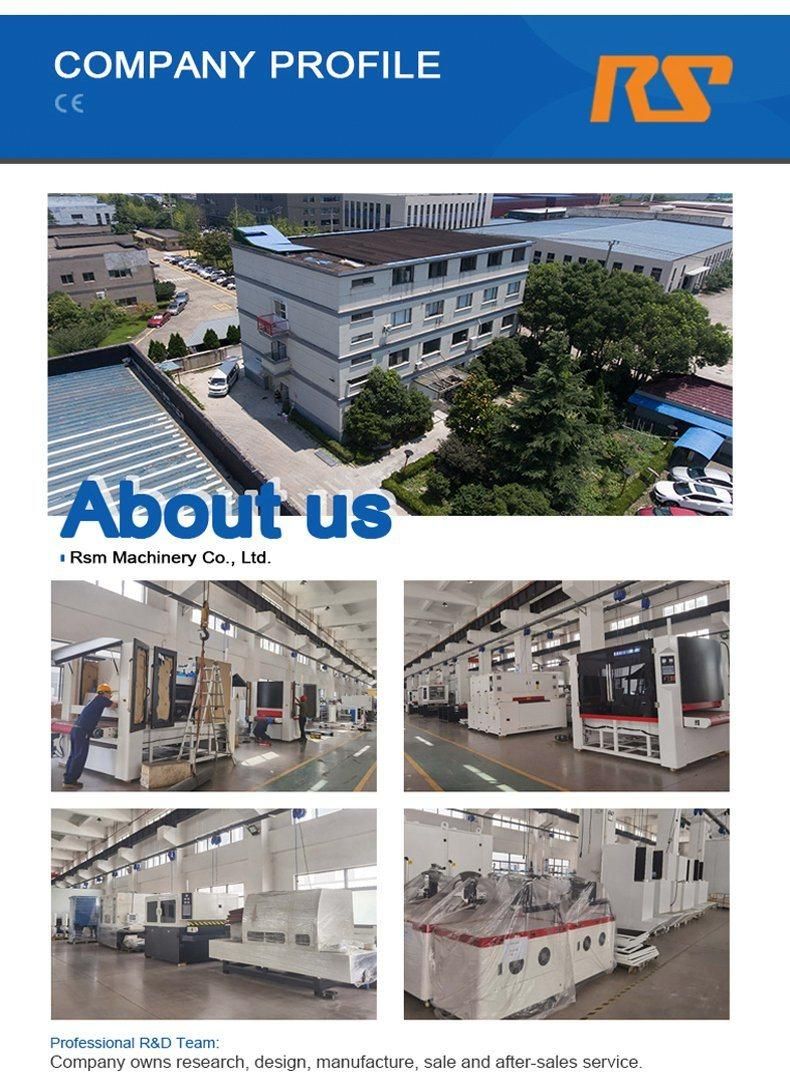

RSM Machinery Co.,Ltd.- After-sales Service:Online Video

- Warranty:12 Months

- Certification:CE

- Condition:New

- Voltage:380V

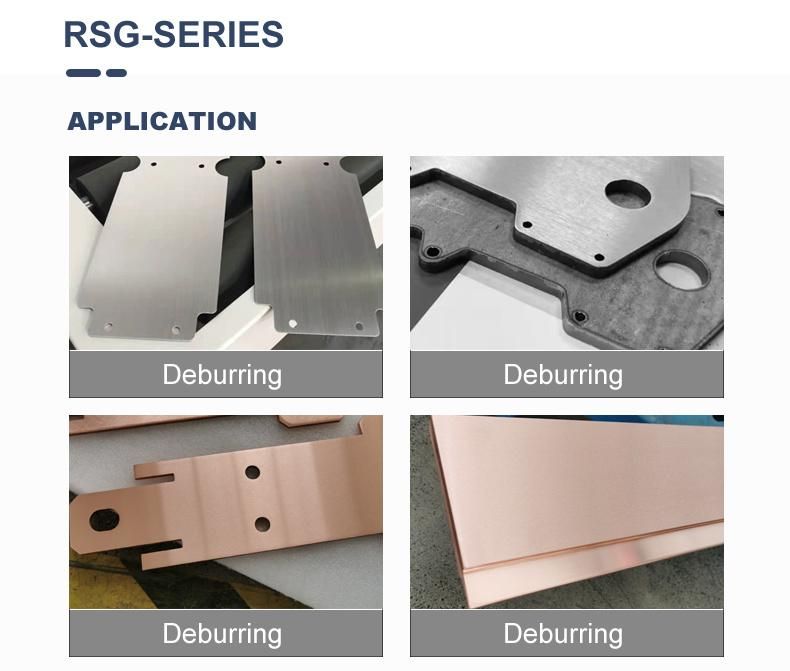

- Application:Metal Sheet

Base Info

- Model NO.:RSG-350

- Total Power:31.2kw

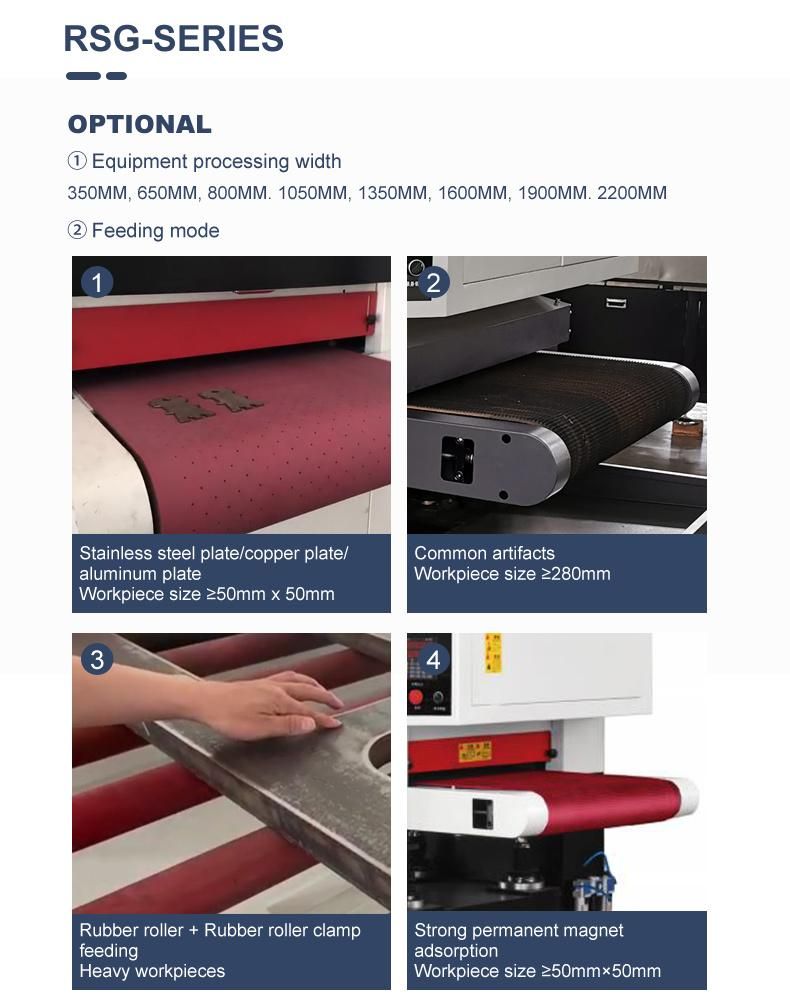

- Max Processing Width:2200mm

- Processing Thickness:1-80mm

- Feeding Speed:2-11m,Min

- Equipment Noise:<80dB

- Polishing Wheel Speed:20m,S

- Belt Speed:18m,S

- Transport Package:Export Wood Box

- Specification:2800*1650*2050mm

- Trademark:RS

- Origin:Shanghai, China

- Production Capacity:10 Pieces,Month

Description

FAQ

1. How many series do you have?

A: We currently offer RMD,PMP,RSP,RSB,RSD,RSG.

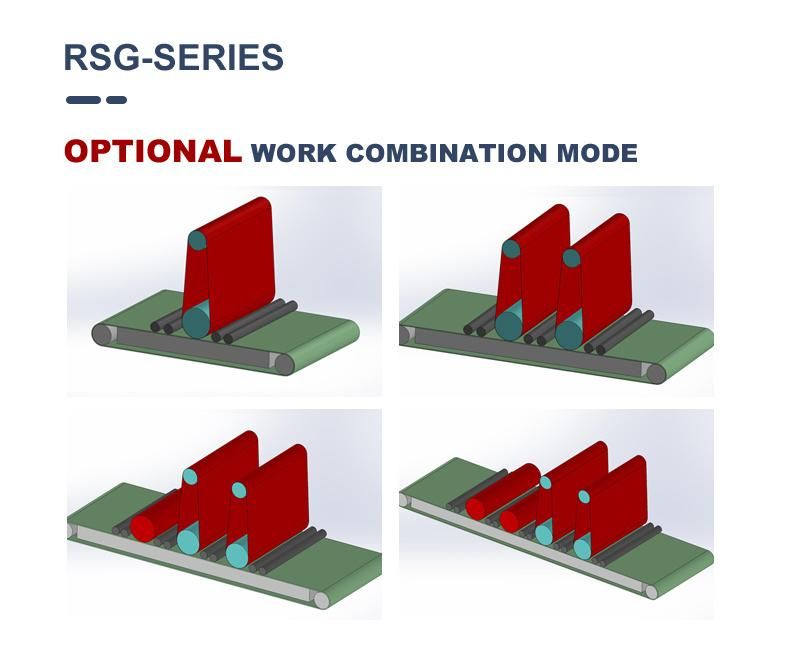

2. What is the equipment combination?

A: Wide abrasive belt+ Universal roller brush single or multiple combination structure

3. What is the equipment combination?What are the functions of the device?

A: Suitable for flat plate parts,carbon steel plate,stainless steel plate,aluminum plate,copper plate,titanium alloy,all kinds of non-ferrous metals,rubber and plastic materials.

4. How do we ensure the safety of workers

A: Matching wet vacuum cleaner or industrial pilse vacuum cleaner to treat grinding dust to achieve environmental protection production