Horizontal Automative Aluminum PVD Evaporation Vacuum Coater Vacuum Plating Coating Machine Vacuum Metallizing Machine for Different Plastic Products

Shandong Zhongpump Power Equipment Co., Ltd.- After-sales Service:Support

- Warranty:1-3 Years

- Type:Coating Production Line

- Coating:Vacuum Coating

- Substrate:Steel

- Certification:CE, ISO, RoHS, REACH

Base Info

- Model NO.:PVA Coating Machine

- Condition:New

- Structure Type:Vertical or Horizantal Type

- Control System:Auto &Manual

- Kinds of Coating:Tin, Ticn

- Machine Size:Custom Made

- Paint Color:Gold, Rose Gold, Blue, Gray, Black

- Process:Environmental

- Transport Package:Export Wooden Box

- Specification:Please check the following product details

- Trademark:SD Pump Power

- Origin:Shandong, China

- HS Code:8543300090

- Production Capacity:500 Set,Month

Description

Basic Info.

Model NO. PVA Coating Machine Condition New Structure Type Vertical or Horizantal Type Control System Auto &Manual Kinds of Coating Tin, Ticn Machine Size Custom Made Paint Color Gold, Rose Gold, Blue, Gray, Black Process Environmental Transport Package Export Wooden Box Specification Please check the following product details Trademark SD Pump Power Origin Shandong, China HS Code 8543300090 Production Capacity 500 Set/MonthProduct Description

Vertical/Horizontal Evaporation Coating Machine:

Principle:

About forms the coating, First, the coating using the powerful current source (tungsten filament) heating, Then hangon tungsten aluminum or aluminum (chrome) melting Aluminum (Cr) material is evaporated, and scattered to adhere to the various aspects of the member to be plated. Melting aluminum (Cr) aluminum (Cr) atoms exist in amorphous or liquid state and is attached to the plate member, so that after cooling into a crystalline aluminum (Cr) film

Applies to:

Plastics, ceramics, glass, resin, candles, and metal materials, etc.

Widely used:

Crafts, gifts, hardware appliances, accessories, cosmetics, automotive and other industries

Main features:

1. No environmental pollution, the film non- toxic, harmless to human body.

2. Double-door, two evaporation electrode configuration, clamping convenient, efficient and time - saving.

3. Turret rotation and revolution, reversible, smooth and flexible.

4. Pumping speed, high efficiency, energy saving.

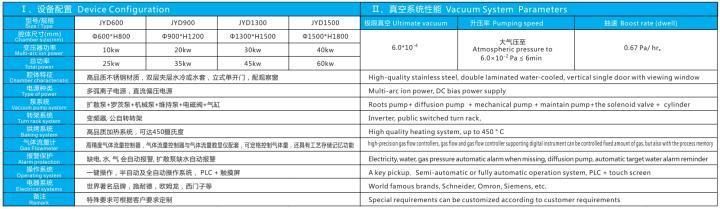

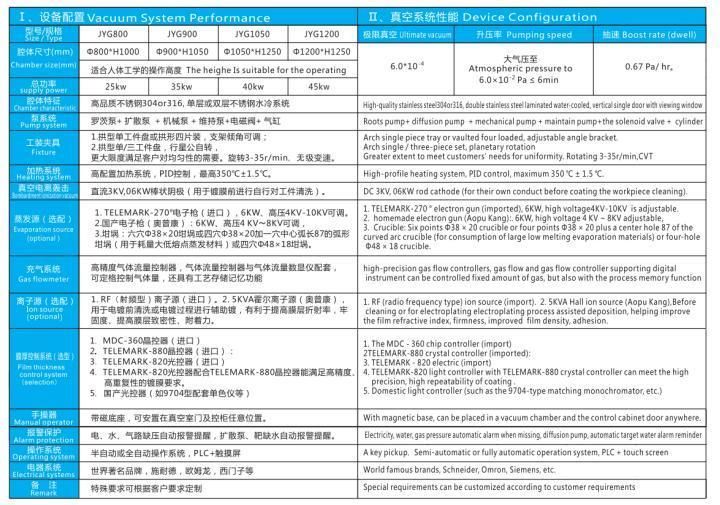

Technical Parameters:

Multiple Arc Ion Coating Machine:

Principle:

Lon plating in a vacuum chamber, Use gas discharge or partially ionized substances evaporate, In the gas ion bombardment or evaporated particles material,of the same time, The vaporized material or reactant deposited on the substrate, The glow discharge ion plating phenomenon, plasma and vacuum evaporation techniques combine the three, Not only can significantly improve the film quality, But also expanded the scope of application of the film, The advantage is that the film adhesion, good diffraction, extensive membrane.

Applies to:

Metal, ceramics, glass and other materials of the surface coating Various hard metal film, a metal compound film and the decorative film.

Widely used

In watches,glasses information products,tools,model,metal,glass,ceramics, building materials and other industry.surface treatment

Main features

1.No environmental pollution, the film non-toxic, harmless to human body, is an alternative to traditionalwater plating gold plated, chrome plated ideal equipment.

2.Stable arc target and power, low-voltage arc, arc spots stable, easy to run arc current is low, small ionparticles;

Technical Parameters:

Magnetron Sputtering Coating machine:

Principle

Magnetron sputtering is the working principle of the electric field E electrons in the substrate during the fly collide with argon atoms, to produce an ionized Ar ions and new e n; The new electronic fly substrate, Ar ions accelerated in the electric field toward the cathode target, and high energy bombarding the target surface, so that the occurrence of the sputtering target. Since the electron energy is low, the energy transfer to the substrate is small, resulting in a lower substrate temperature.

Widely used:

Watches, glasses, communications, electronics, machinery, and transportation and viation decorative , high- end decorative and functional film

Main features:

1.No environmental pollution, the film non-toxic, harmless, high- -end decorative and functional films.

2. In the film deposition device density, uniformity, purity, hardness, adhesion, etc. are improved.

3. The deposition rate, and temperature is low, can be used for plastic, glass ceramics, hardware products.etc, high-end film

Technical Parameters:

Electron Beam Optical Lens Coating Machine:

Applicable Areas:

This machine is mainly used for plating various films such as transparency enhanced film, spectroscopic film, band pass filmcutoff film, and high reflection film It can plate a super large film system with 100 lays of film, and a transparency enhanced film with various colors, a reflection film with a red, yellow, blue, green or rainbow color.

Main Configuration:

The vacuum chamber is a vertical type boxed structure wit a front door; the box is completely made of stainless steel; dimensions of the internal cavity are Ф800mm - Ф 1800mm;

Vacuum System Configuration: with molecular pump (or diffusion pump), Roots pump, mechanical pumps.

Deep Cooling System with a Fast Cycle Water Vapor Cryopump

Work Piece Rack is an integrated arched shape work piece, can be customized according to the customer.

Coating System is equipped with one or two sets of high power e-type 2700 magnetic deflection electronic gun scanning in XY directions. The auxiliary metallization system is equipped with a Holl ion source.

Baking :Digitally displayed and automatically controlled with a temperature control precisionof *1.5C.

The film thickness monitoring system can control evaporation rate of the electronic gun. The optical film thickness monitoring system, in which the wave length is controlled within the range of 200-900mm.

Control System: The vacuum is controlled by a 10.4 inches color touch screen coupled with a programmable logic otoller. The vacuum and Coating process are controlled fully automatically.

Technical Parameters:

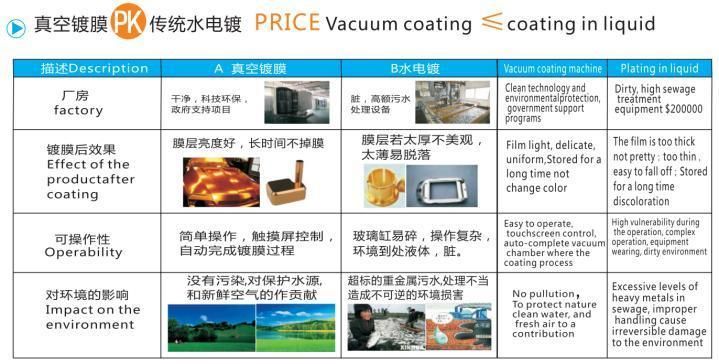

Vacuum Coating Machine PK Plating in liquid: