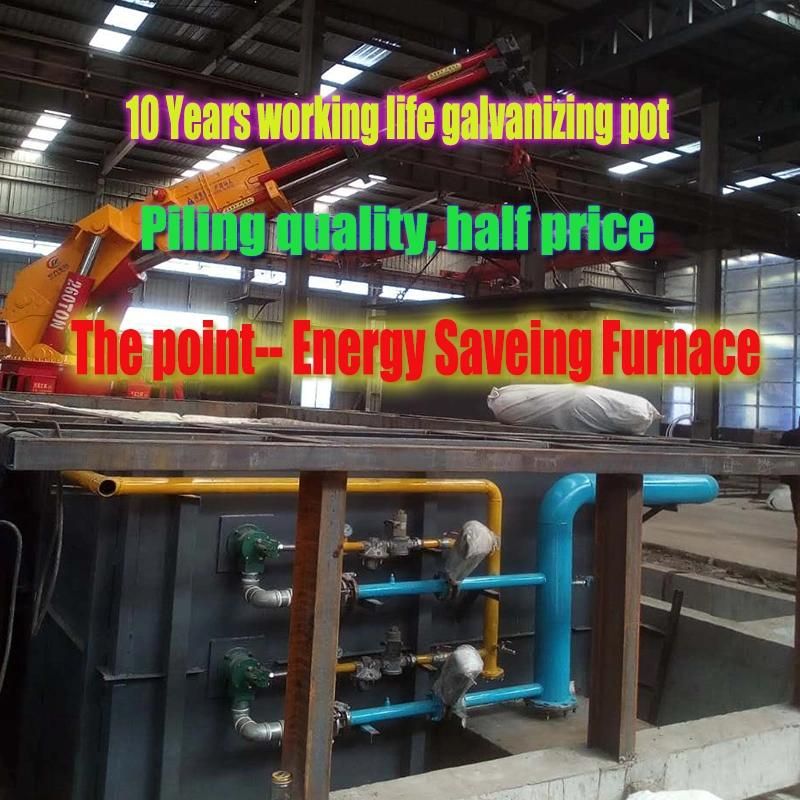

CNG Energy Saving Hot DIP Galvanizing Melting Zinc Pot Galvanizing Kettle with Galvanizing Furnace

Hebei Annuo Automation Technology Co., Ltd.- After-sales Service:Long Life

- Warranty:Long Life

- Type:Coating Production Line

- Coating:Galvanized

- Substrate:Steel

- Certification:CE, ISO

Base Info

- Model NO.:HDG-ZPF

- Condition:New

- Material:Steel (Angang Xg08), Ceramic

- Heating Method:Electric, Steam, Hot Water or Other

- Steel Plate Thickness:50mm, 60mm

- Shape and Size:Customized

- Delivery Term:Fob, CIF, CNF

- Characteristic:Low Si, C, S, P, Long Service Life

- Working Life:8-10 Years

- Furnace Fuel:CNG, LNG, Electric Power, Oil

- Transport Package:Bulk

- Specification:Customized

- Trademark:Annuo

- Origin:Hebei, China

- HS Code:73090010

- Production Capacity:300 Sets,Year

Description

The features of manufacturing process:

- We recheck the chemical composition of steel plate one by one after the steel materials arrive in our factory.

- Strict quality control, reliable quality. We do 100% Ultrasonic Test to the steel plate and the welding line strictly complying with the national standards GB/T11345-1989.

- Rational use of plate width to reduce the welding line.

- Weld position are as per customer's requirements or as per the characteristics of the furnace, keep away from the heating area.

- The finished galvanizing pot must be Ultrasonic Tested before sending to customers.

- Automatic Firing system, saving energy! Only need 3 years, you can save a new zinc pot!Heating Furnace for Hot

High velocity pulse fired system is fixed at the corner of galvanizing furnace, the combustion air continuously surrounds the zinc pot by the flue duct.

The thermal conductivity of the heat evenly passes to each point of zinc pot, which also absorbs heat generated by the burner. It can greatly prolong kettle life.No.3: To Know Us BetterIf you want to know whether you money is worth to buy our equipment and whether our company has the ability to meet your requirements, we are expecting a facial conversation with you to solve your questions and to let you know what can we do.

Related ProductsHeat system Krom,Honeywell,Dungs Electronic control Siemens Insuation module Morgan or Isolite Japan The combustion stability is greatly improved, the combustion is uniform, stable, energy-saving, and the service life of the zinc pot is prolonged.

Our furnaces can save customers' production costs!We have higher cost performance!

If that product interest you, please contact us.!

Related Products:

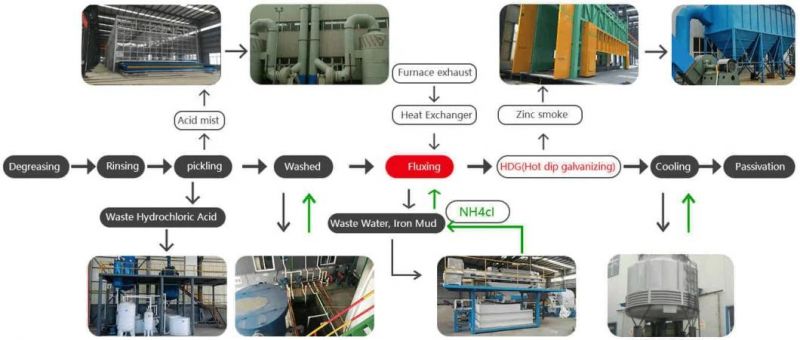

Technical Process for Galvanizing line:

Certificates:

All products are CE Authentication

Five Advantages:- Technical advantages

Strong research team including 50 experts, professors, senior engineers and other high-tech R&D specialists.

Established strategic partnership with famous universities and research institues in China and abroad.

World-Class leading hot-dip galvanizing techniques.

Latest concept of factory and production line design.

Capability of new equipment invention and development.- Planning and design advantages of whole production line

- Quality advantages

- Project construction advantages

- Service advantages