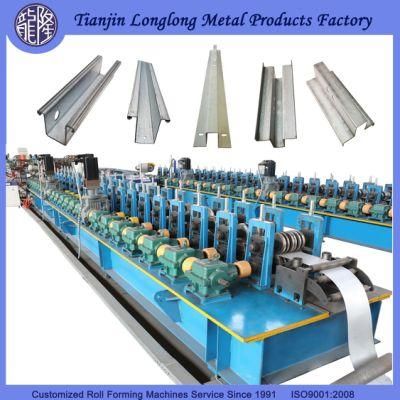

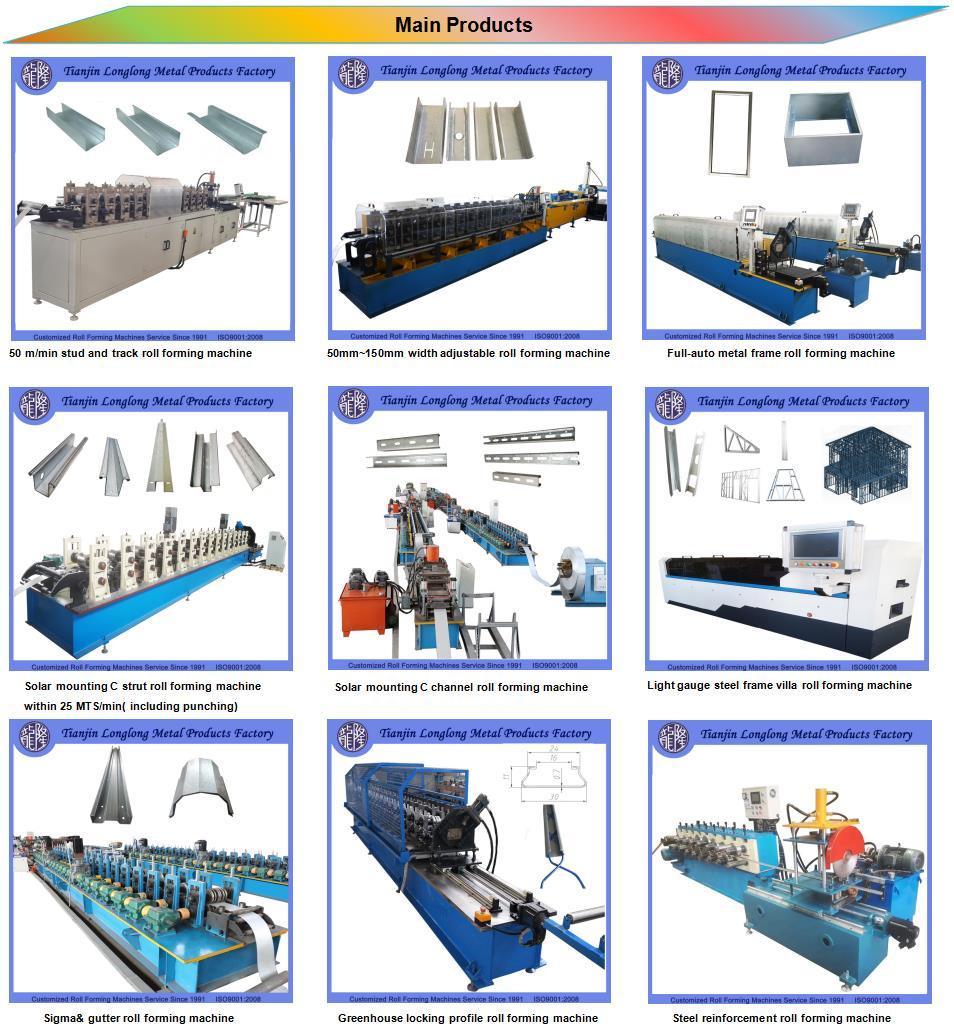

PV Steel Purlin C/U/Custom Profile/Steel Channel Roll Forming Machine for Solar Mounting Brackets Roll Former Factory

Tianjin Longlong Metal Products Factory- After-sales Service:Whole Life

- Warranty:One Year

- Cutting:Auto

- Speed:10-30 Meters,Min

- Roller Material:Cr12 MOV

- Drive:Gear Box

Base Info

- Model NO.:LL-70-24

- Power:37.5kw

- Control:PLC Control

- Transport Package:Main Machine Bulk and Spare Parts by Wooden Box

- Specification:1.8mm~3.0mm

- Trademark:LONGLONG

- Origin:Tianjin China

- HS Code:84552200

- Production Capacity:50sets,Month

Description

LL-70-24STMain components list -- Whole Line No. Item Unit Qty 1 Decoiler Set 1 2 Roll Forming machine Set 1 3 PLC Set 1 4 Hydraulic station Set 1 5 Cutting device Set 1 6 Punching device Set 1 7 Collector Set 1

Advantage

Advantage

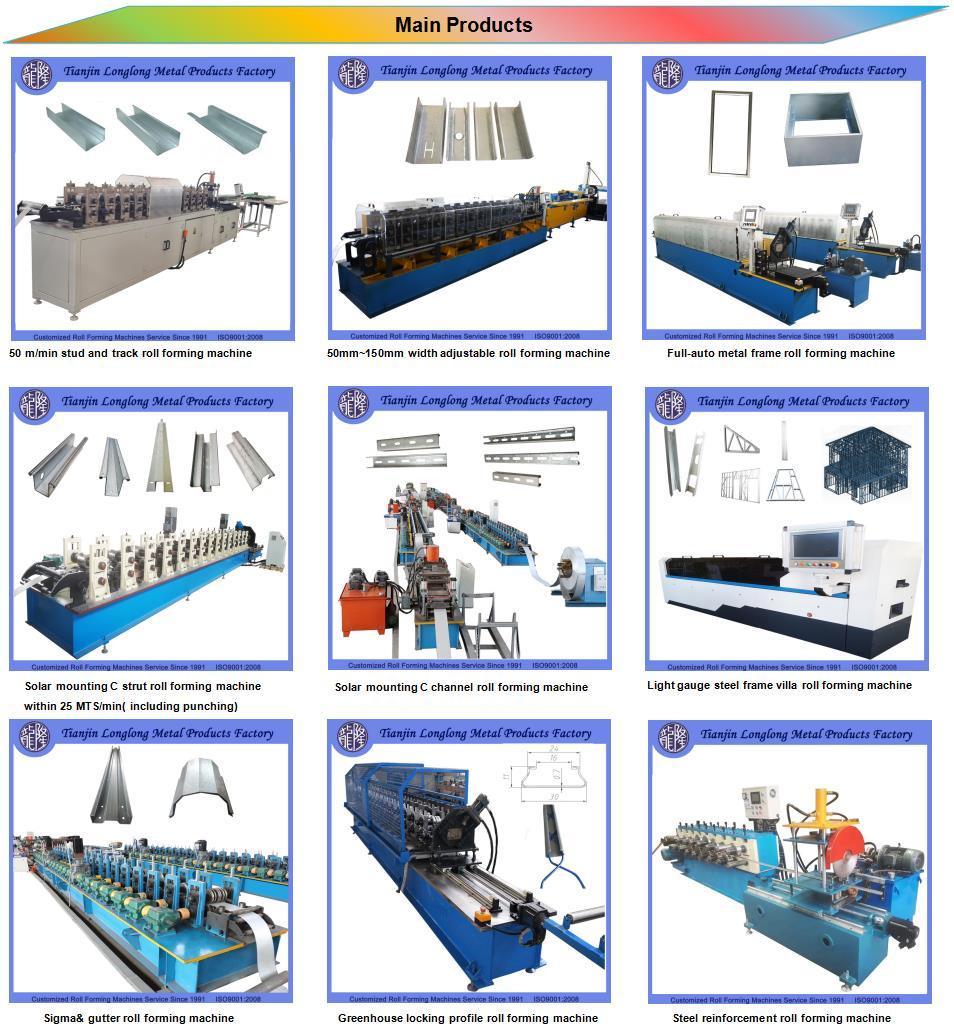

1.We are manufacturer and have export entitlement.

2.We have more than 30 years' experience, our products have been exported to more than 80 countries all over the world.

3.We supply manufacturing, design, installation, after-sales and other services.

FAQs

1.Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.

We need your machines running in order to keep your business running.

2.How to visit your company?

a. Fly to Beijing airport, we can pick up you.

b. Fly to Tianjin Airport, we can pick up you.

3.How to get a quotation?

a. Give me the profile drawing and thickness, this is the important. If no, I will suggest you some.

b. Other specific requirements are welcome, such as the speed, power and voltage you want.

4.You are trade company or factory?

We are factory. Welcome to our workshop for visiting.

5.Can you be responsible for transport?

Yes, please tell me the destination port or address. We have rich experience in transport.

6.How long the machine could be made?

Normally speaking, common roll forming machine could be made within 45 working days.

If you need machines in a hurry, we can make it for you less than a month.

| Production process flow chart: uncoiling → Leveling → pre punching → roll forming → hydraulic&servo tacking cutting → collection |

| Process description |

| The type production line can produce variety of sizes steel through changing punching molds.cutting, all sizes of punching and cutting length are measured directly by the counter, and the size is set arbitrarily in the man-machine interface. |

Advantage

Advantage1.We are manufacturer and have export entitlement.

2.We have more than 30 years' experience, our products have been exported to more than 80 countries all over the world.

3.We supply manufacturing, design, installation, after-sales and other services.

FAQs

1.Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.

We need your machines running in order to keep your business running.

2.How to visit your company?

a. Fly to Beijing airport, we can pick up you.

b. Fly to Tianjin Airport, we can pick up you.

3.How to get a quotation?

a. Give me the profile drawing and thickness, this is the important. If no, I will suggest you some.

b. Other specific requirements are welcome, such as the speed, power and voltage you want.

4.You are trade company or factory?

We are factory. Welcome to our workshop for visiting.

5.Can you be responsible for transport?

Yes, please tell me the destination port or address. We have rich experience in transport.

6.How long the machine could be made?

Normally speaking, common roll forming machine could be made within 45 working days.

If you need machines in a hurry, we can make it for you less than a month.