CNC Machined Customized Anodized Non-Standard Aluminum Optic Lens Holder

Wuhan ZHD Precision Technology Co., Ltd.- After-sales Service:Rework If The Problem Is Due to Our Responsibility

- Warranty:Rework If The Problem Is Due to Our Responsibility

- Condition:New

- Certification:RoHS, ISO9001

- Standard:DIN, ASTM, GB, JIS, ANSI

- Customized:Customized

Base Info

- Model NO.:According to Customers′

- Material:Alloy

- Application:Optic Device

- Designing:Available

- OEM:Available

- Surface Process:Multi-Option

- Transport Package:Carton

- Specification:800X500X300mm

- Trademark:ZHD

- Origin:Wuhan, China

- HS Code:8401200000

- Production Capacity:5000PCS,Year

Description

Basic Info.

Model NO. According to Customers′ Material Alloy Application Optic Device Designing Available OEM Available Surface Process Multi-Option Transport Package Carton Specification 800X500X300mm Trademark ZHD Origin Wuhan, China HS Code 8401200000 Production Capacity 5000PCS/YearProduct Description

Note: This product is just a sample part we once machined according to a customer's drawing, and the price shown on this page is NOT the real price.Our procedure for customizing parts for you is as follows:

- Customer provides 2D or 3D drawings;

- We quote the prices according to your drawings(we can also design the parts according to your specific requirements);

- Orders are confirmed by both parties;

- We start to put your parts into machining;

- We package and deliver the parts the customer;

Description of This Part

Material:

2A12-T4

Product Use:

Holder for optical lens

Machining characteristics:

1.Lathe rough turning, stock left out.

2. CNC 4-axis rough machining.

3.Aging treatment to fully remove the cutting stress in the workpiece.

4.Lathe finish machining, dimensions machined to the requirement, cylindricity of installation positions of internal optical components is within 0.007mm, and concentricity within 0.01mm.

5.The shaft is to be finished by milling inside and outside the workpiece, and the position accuracy, perpendicularity and flatness shall be within 0.02mm.

Surface Treatment:

Black anodizing, meeting the requirements of environmental protection

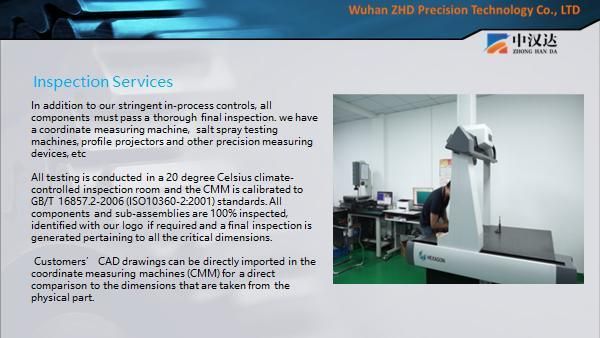

Inspection:

The places where accuracy is required meet the requirements of drawing, and the flatness and perpendicularity are within 0.02mm, and cylindricity 0.007mm, and co-axiality 0.01mm. it is inspected with CMM, and finished product reports from CMM are generated.