Advanced Non-Contact Series Ultrasonic Assisted Milling & Drilling Machine

Hangzhou Shengpai Technology Co., Ltd.- Warranty:One Year

- Condition:New

- Certification:CE

- Customized:Customized

- Material:Stainless Steel

- Application:Metal Processing Machinery Parts, Ultrasonic Milling and Drilling

Base Info

- Model NO.:SP-AM20

- Frequency:20kHz

- Power:500watt

- Spindle Mode:Bt, ISO, Hsk, Cat

- Amplitude:More Than 10um

- Speed:20000 R,Min

- Matching Tool:Carbide End Mill Head Diameter 2- Diameter13

- Leading Time:30 Working Days

- Transport Package:Wooden Case

- Trademark:SP

- Origin:China

- HS Code:8543709990

- Production Capacity:1000pieces,Month

Description

Using wireless transmission technology. For surface-to-surface or ring-to-ring, the emitter can be 1/4 circle to whole round, adapt to different processing machine and machining center, and realize the quick cutters change.

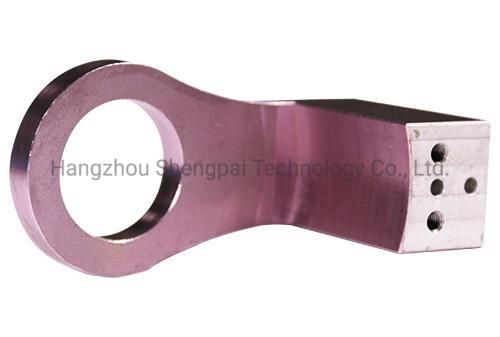

3. Amplitude Transformer

Amplitude Transformer with vertical-twisted design made two dimensional ultrasonic machining come true. Torsional vibration is applied in the direction of main cutting speed, which can greatly reduces cutting force and cutting heat. Cutting force can reduce 1/3 compared with traditional cutting. For multi-dimensional vibration, cutting force decreased 1/16 of common cutting. The cutting temperature is less than 1/3 of the ordinary machining.

Amplitude Transformer with vertical-twisted design made two dimensional ultrasonic machining come true. Torsional vibration is applied in the direction of main cutting speed, which can greatly reduces cutting force and cutting heat. Cutting force can reduce 1/3 compared with traditional cutting. For multi-dimensional vibration, cutting force decreased 1/16 of common cutting. The cutting temperature is less than 1/3 of the ordinary machining.Taking the lead in putting forward the part-resonance design theory of high speed ultrasonic holder. Through the ultrasonic barrier technology, all connecting place is vibration null point. There is no influence on the spindle and ensure the safe operation of the machine.

Advantage:

The ultrasonic processing can be used for high speed milling,drilling, grinding, and boring.

Under the same condition, the surface roughness can be increased byone magnitude. For processing of hard and brittle materials, the machiningefficiency can be increaseed 100% than that of the traditional machining.The tool lifespan can be increased more than 3 times.

Applications:

1. Various kinds of materials especially fragile rigid material.

2. Processing plane, groove, all kinds of form surface (such as spline, gear and thread) and special surface of mould.

3. Application area: machining industry, machine tool equipment manufacturing.

4. Application occasion: manufacturing enterprise, universities and colleges, scientific research institution, mechanical equipment transformation industry.