-

OEM Iron CNC Precision Parts Bed Casting Milling Machine Base with Good Price Custom Tool

Basic Info. Model NO. Custom machine tool casting

-

±0.2592.5018.318.03309.02.3097.9519.319.03309.72.00103.3920.320.033010.0±0.52.50108.83Product Show:More information, please kindly contact us.Best regardsGrewin carbide

-

New Hot UPVC Window Fabrication PVC Profile Double Head Cutting Saw China Factory

Product Name:CNC Automatic Double Head Mitre Saw for AluminumPower Supply:380V/50Hz or CustomizedCutting Height:160mmCutting width:120mmCutting Angle: -45,90 and 45 degreeSpecificationPower Supply380V/50Hz or CustomizedModelDS1-STB450-3700-2Motor RPM2800r/minCutting Width*height120*160mmCutting Angl

-

High Capacity Nails Equipment Manufacturing Steel Nail Making Machine

Overview Product DescriptionProduct ParametersCertificationsPackaging & ShippingOur CustomersCompany Profile

-

Overview Product DescriptionPackaging & ShippingCompany ProfileFAQQ: Are you trading company or manufacturer ?A: We are factory.Q: How long is your delivery time?A: Generally it is 5-10 days if the goods are in stock. or it is 15-50 days if the goods are not in stock, it is ac

-

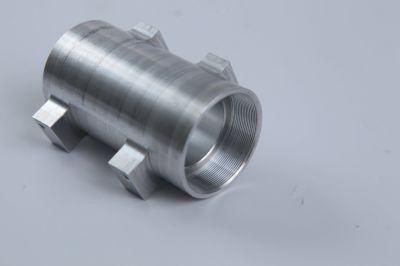

OEM Turning Milling Aluminum 6061 Metal CNC Machining Service

Overview Company ProfileProduct DescriptionCertificationsPackaging & ShippingAfter Sales ServiceFAQAre you factory?Yes, we are the manufacturer of metal parts by CNC machiningwith rich experience.What's your advantage?We providenon-standard//OEM//customized service.How long is

-

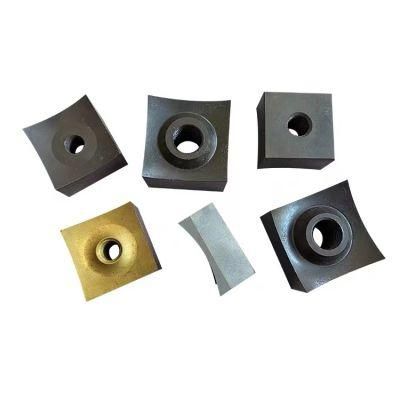

Factory Price Tungsten Carbide Tools Aluminum Inserts Tcgt CNC Aluminum Tools for Cutting

500000 pieces in stockPacking of milling insertsInner packagePlastic box,normally 10 pcs in a box, other customized pacakge are avaliable.Exterior PackageStandard high quality paper cartons.Company InformationZhuzhou OBT Carbide Tools CO.,Ltd is a professional producer for solid carbide end mills, i

-

High Quality Hot Forging Ring Custom

Basic Info. Model NO. RXT-2615

-

High Quality OEM Auto Parts New Alloy Materials Engine Valve Seats

The Advantage of Powder Metallurgy Process1. Cost effectiveThe final products can be compacted with powder metallurgy method ,and no need or can shorten the processing of machine .It can save material greatly and reduce the production cost .2. Complex shapesPowder metallurgy allows to obtain complex